Low Frequency vs High Frequency Inverters:

4 days ago · There are two main types of frequencies to be compared: low frequency vs high frequency inverters. The inverter frequency determines the

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter, also known as a variable frequency drive (VFD), is an essential device used to control the speed and torque of electric motors by adjusting the input

Low frequency inverter vs high frequency

Mar 12, 2025 · When choosing an inverter for your solar system, one of the key decisions is whether to use a low-frequency inverter or a high-frequency

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency and low-voltage alternating current;

Frequency inverters

The tasks and function of a frequency inverter are varied depending on the model, for example the " frequency inverter 400v " or " frequency inverter 230v ", and

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · Line-Frequency vs. High-Frequency Inverters: A Technical Deep Dive for Engineers In the world of power electronics, the inverter is a cornerstone technology, responsible for the

The difference between a high and low frequency inverter

2. Low Frequency Inverters: Robust and Durable: Low frequency inverters are better suited for applications requiring high power output and reliability. Their robust design allows them to

Technical comparison between Low Frequency

Aug 19, 2025 · What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output

How to Distinguish High Frequency Inverter and Low Frequency Inverter

Apr 11, 2024 · The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer

Low Frequency vs High Frequency Inverters:

4 days ago · A low-frequency inverter is a superior choice if you need an inverter for heavy-duty applications that require handling high surge loads—such as

Understanding the Difference Between

Jan 21, 2025 · Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power

Low Frequency VS High Frequency Inverter

May 2, 2023 · Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for

What is a High-Frequency Power Inverter?

1 day ago · Introduction A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize

What are the Types of Frequency Inverter?

Oct 22, 2023 · These frequency converters are typically used in low-power applications and high-frequency applications. Frequency inverters are

Inverters High or Low Frequency ? | DIY Solar Power Forum

Apr 15, 2020 · Low-frequency inverters use high-speed switches to invert (or change) the DC to AC, but drive these switches at the same frequency as the AC sine wave which is 60 Hz (60

The differences and similarities between high-frequency inverters

Industrial frequency inverters are usually used for higher power applications, such as home power systems, industrial power, etc. High frequency inverters are often used in applications that

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · Yet, not all inverters are created equal. One of the most critical architectural decisions an engineer faces is the choice between a line-frequency (or low-frequency) and a

What is Frequency Converter? How it works?

But, it will always be there in high quality, general purpose frequency converters (those manufactured by dedicated frequency converter manufacturers).

Harmonic Overload: Impacts Of High-Frequency

5 days ago · During the CIGRE Grid of the Future symposium and workshop, harmonics were recognized as a critical focus in modern electrical systems,

The difference between high frequency and industrial frequency of inverter

What is the difference between industrial and high-frequency inverters? Industrial frequency inverters have high stability and are suitable for high-demand occasions; high-frequency

Low-Frequency vs. High-Frequency Inverters:

Dec 3, 2024 · Introduction When selecting a solar inverter, understanding the difference between low-frequency and high-frequency models is essential.

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · Power Frequency Inverter vs High-Frequency Inverter- Which One Should I Prefer? To conclude, power-frequency inverters and high-frequency inverters each have pros

What is the difference between a high frequency

Apr 25, 2024 · Since the high-frequency inverter uses small-sized, lightweight high-frequency magnetic core materials, the power density of the circuit is

Frequency inverter basics

Frequency inverters are widely used throughout industry to provide adjustable speed control of ac motors. Although modern versions are relatively simple to

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

High-frequency versus low-frequency inverters which is right

Jun 13, 2025 · Key Takeaways High-frequency inverters are small, efficient, and cost-effective, making them ideal for light loads and limited spaces like homes and offices. Low-frequency

Is it better to choose industrial frequency or high frequency inverter

Aug 23, 2024 · Compared with industrial frequency inverters, the operating frequency of high-frequency inverters is significantly higher, usually up to several thousand hertz or even higher.

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

A Complete Guide to Inverters/Variable

Jan 1, 2025 · There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical

Demystifying High Frequency vs Low Frequency

Jul 2, 2023 · The main difference between High-frequency and Transformer-based Low-Frequency Inverters/UPS is the frequency at which they operate.

What is the difference between a low frequency inverter and a high

Feb 6, 2025 · Low-Frequency Inverter: Operates at a lower frequency, typically around 50Hz or 60Hz. Because its frequency is close to that of utility power, it is suitable for applications

Low Frequency vs High Frequency Inverters: Key

Aug 15, 2025 · Explore the key differences in low frequency vs high frequency inverters including their applications, advantages, and which is best for your

6 FAQs about [Is the inverter industrial frequency or high frequency]

What is a high frequency inverter?

A high-frequency inverter is a type of power inverter that uses advanced electronic switching technology to convert DC into AC. Instead of heavy transformers, these inverters use smaller, lightweight components that operate at very high switching speeds (several thousand Hz). High-frequency inverters are compact, lightweight, and efficient.

What is the difference between low frequency and high frequency inverters?

Low-frequency Inverters are designed to handle high-surge loads, typically 2-5 times their rated power output. This makes them perfect for refrigerators, compressors, or air conditioners requiring extra power during startup. High-frequency inverters typically have 1.5-2 times their rated power, which limits their surge capacity.

What is a frequency inverter in pool pumps?

A frequency Inverter is a device that converts the alternating current of one frequency to another frequency for motor speed change in a pool pump application. The majority of pool pumps installed in the market now are single speed, which are quite powerful when used for heavy-duty operations such as backwash.

What is a low frequency inverter?

Low-frequency inverters are known for their durability and ability to handle high surge loads. The heavy transformers inside these inverters allow them to deliver much power for short bursts, which is essential for starting devices like refrigerators, air conditioners, or power tools that need extra energy to start running.

Should you buy a high-frequency inverter?

On the other hand, if you’re looking for a portable solution for RVs, boats, or small solar setups, a high-frequency inverter is ideal for powering lighter loads, such as laptops, LED lights, and small electronics.

Are low frequency inverters reliable?

These transformers operate at lower frequencies (typically 50 or 60 Hz), making them robust and highly reliable. Low-frequency inverters are known for their durability and ability to handle high surge loads.

Industry Information

- How many photovoltaic panels are needed to generate 3 kilowatts of electricity

- Togo s new energy storage requirements

- Solar energy on site works 24 hours

- House inverter system factory in Hungary

- Finland Flexible Container Wholesale

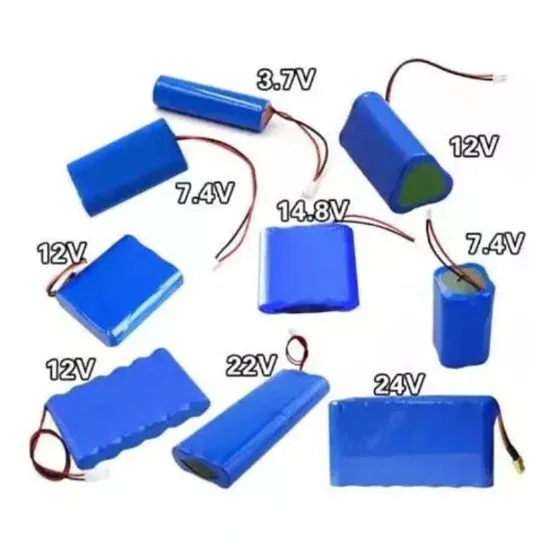

- Production of simple lithium battery pack

- Berlin Energy Storage Lithium Battery Price

- Guatemala City lithium battery pack custom manufacturer

- How many kilowatts does a solar panel generate

- High quality factory price solar powerbox Wholesaler

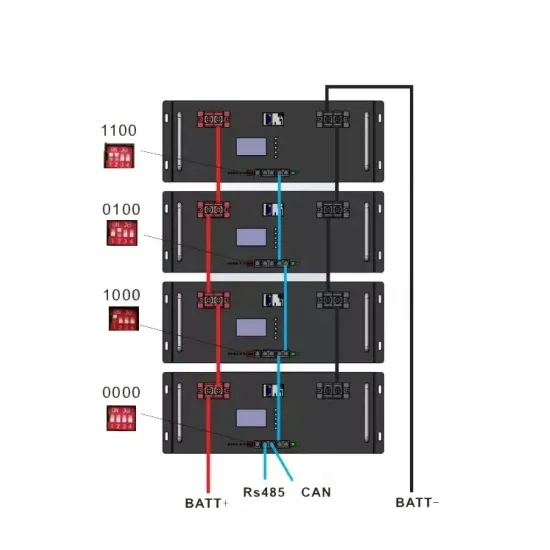

- Modular energy storage power station battery compartment installation

- Outdoor prefabricated cabin energy storage system

- Power management system for Hargeisa base station

- San Salvador Air Energy Storage Power Station

- Photovoltaic power station inverter

- Ups lithium iron phosphate battery station cabinet

- Photovoltaic glass composition lithium

- What are the special batteries for household energy storage in St Petersburg Russia

- Factory price 110 amp breaker in Guinea

- Application prospects of energy storage power stations

- Does the capacity of lithium battery packs have to be consistent

- Solar 220V power generation system

- Solar Inverter Quote

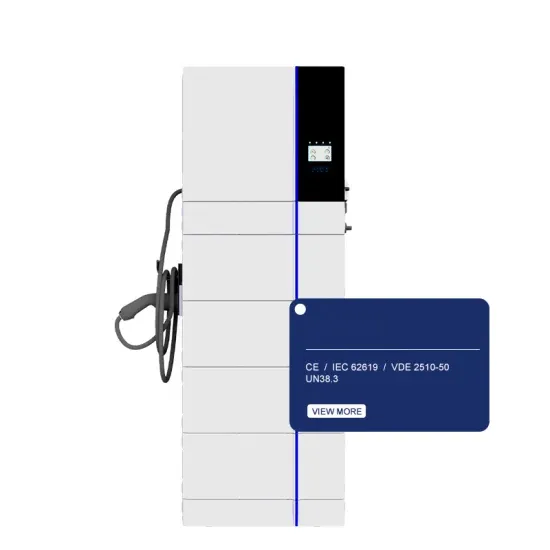

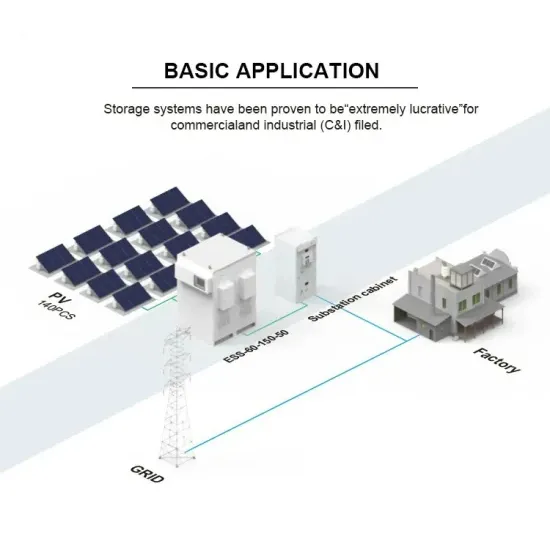

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.