Lithium Battery PACK Production Line Processes

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design,

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Current manufacturing processes for LIBs LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature

The Complete Guide to Lithium Ion Battery

Jul 18, 2023 · Every stage of the lithium-ion battery manufacturing process brims with rigorous quality checks, expert skills, and state-of-the-art technology.

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

The Manufacturing Process of Lithium Batteries

Sep 18, 2024 · Lithium battery manufacturing encompasses a range of processes designed to produce efficient and reliable energy storage solutions. The

Basic knowledge and manufacturing process of

Introduction The production process of lithium-ion batteries is divided into four main processes: pole piece production, battery cell (cell) production, cell

Key Points of Lithium Battery PACK

Jun 27, 2024 · Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The Battery Production specialist department is the point of contact for all questions relating to battery machinery and plant engineering. It researches technology and market

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

(Infographics #3) Battery Making at a Glance

Jun 14, 2023 · (Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Unraveling Lithium Battery Pack Production: A

May 10, 2023 · The production of lithium-ion battery packs is complex due to the direct impact of safety performance on consumers'' wellbeing. High

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Lithium Battery Pack Production | Industrialist

Aug 18, 2025 · The Lithium Battery Pack is a great way to make money and is required for the Logic Assembler research for making Microchips. This page

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · From precise cell welding to smart BMS integration—uncover how lithium-ion battery packs are engineered for safety and power.

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Current and future lithium-ion battery

Apr 23, 2021 · Current manufacturing processes for LIBs LIB industry has established the manufacturing method for consumer electronic batteries

How lithium-ion batteries are manufactured

Jul 4, 2025 · How lithium-ion batteries are made in detail—from electrode slurry preparation to final battery pack assembly. Learn about key materials, equipment, and processes used in

Production requirements of lithium battery PACK

May 27, 2024 · Lithium battery processing, production requirements of lithium battery PACK manufacturers. The process of assembling lithium battery cells into groups is called PACK,

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

How Are Lithium Ion Batteries Manufactured

Nov 21, 2024 · Discover the step-by-step process of lithium ion battery manufacturing, from raw material extraction to battery pack assembly,

Lithium Battery Manufacturing Process Revealed:

Jul 6, 2023 · Discover the fascinating journey of lithium battery production, unraveling the secrets behind this cutting-edge technology. From Start To

Lithium Ion Battery Production Line

4 days ago · Lithium Ion Battery Production Line Lithium ion batteries are manufactured on a large-scale production line consisting of electrode formation, stacking, inspection, packaging,

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Lithium-ion Battery Manufacturing Process

Aug 3, 2023 · Lithium-ion battery manufacturing is a complex process. In this article, we will discuss each step in details of the production, meanwhile

PRODUCTION PROCESS OF A LITHIUM-ION

Apr 19, 2023 · Cost‐savings in lithium‐ion battery production are crucial for promoting widespread adoption of Battery Electric Vehicles and achieving

The production of lithium-ion cells

Jan 25, 2023 · When discussing lithium batteries, it is impossible to avoid focusing on their essential component, namely, the cells of which they are

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · The lithium battery module PACK production line is a complex system project involving multiple links and aspects of management and

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · Intro Creating a lithium-ion battery is like piecing together a complex puzzle where every part plays a crucial role in achieving the final goal. These batteries, which power

Lithium battery module design production

Aug 18, 2025 · Key points of lithium battery module structure design Reliable structure: anti-vibration and anti-fatigue. Controllable process: no over

6 FAQs about [Production of simple lithium battery pack]

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

How a lithium ion battery is made?

The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries. The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Industry Information

- Inverter grid-connected box combiner box

- Circulation wind power generation system

- Hybrid power inverter factory in France

- Photovoltaic panel production and manufacturing companies

- St Johns 72v60a battery cabinet

- Prospects for home energy storage battery maintenance

- How much is the subsidy for energy storage batteries in Cordoba Argentina

- Zimbabwe Grid Energy Storage

- Container outdoor power supply light charging

- Hollow photovoltaic panel price

- Base station uses power chip or power supply

- Kyrgyzstan communication base station wind tower manufacturer customization

- 5g base station 1 electricity fee introduction

- Which battery plus inverter is better

- Are there any flywheel energy storage companies in Dhaka

- Shushi New Energy Battery Cabinet

- 220v circuit breaker for sale in Argentina

- Huawei liquid flow battery usage scenarios

- Communication base station solar energy price trend China

- Doesn t the Paris energy storage power station use lithium batteries

- Villa outdoor roof solar lights

- France Energy Storage Cabinet Container

- Energy storage power in solar-storage-charging projects

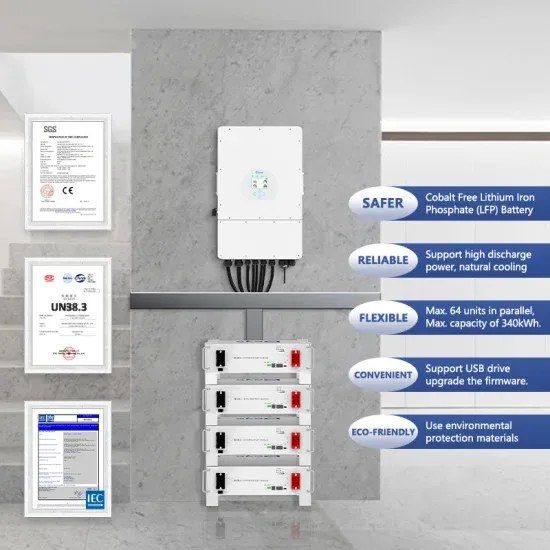

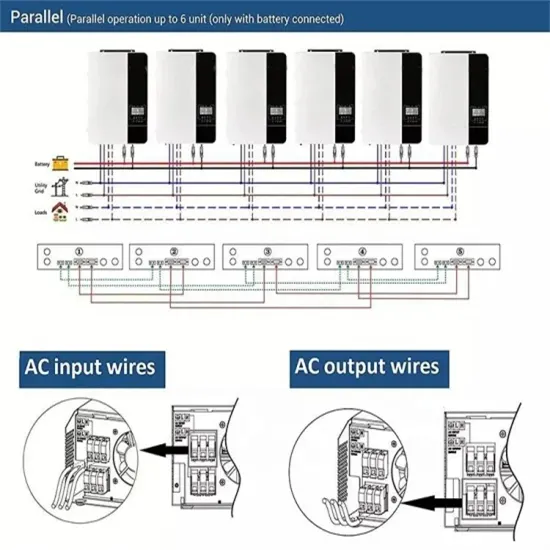

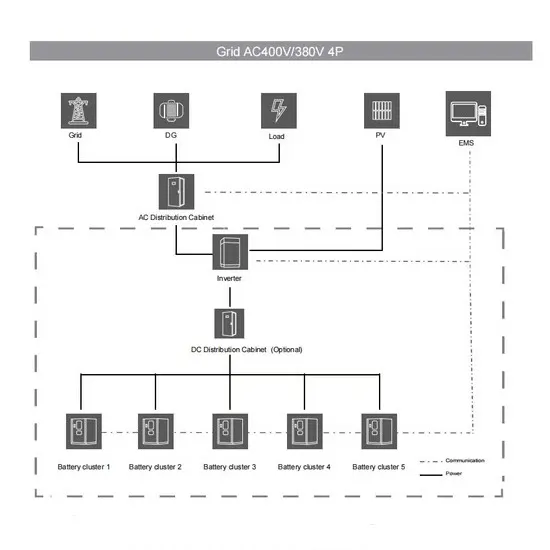

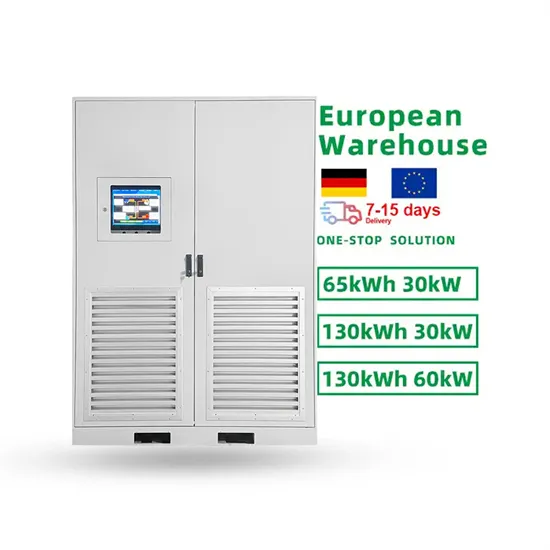

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

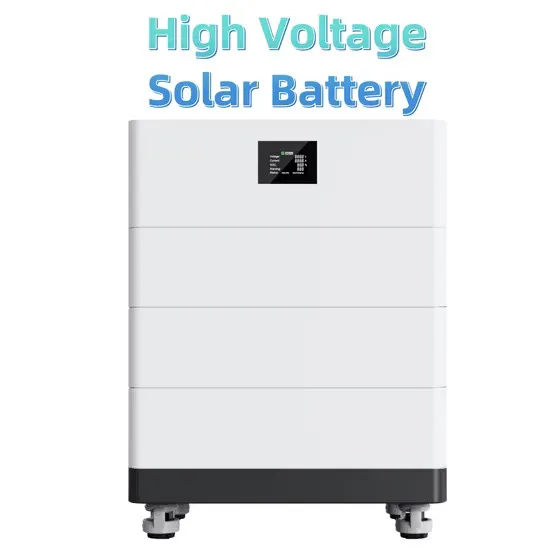

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.