Research on Consistent Separation Method of Lithium

Oct 22, 2022 · Abstract. Lithium ion batteries are widely used in electric vehicles because of their high energy density, small self discharge, long storage time, long cycle life and no capacity

Lithium-ion Battery Consistency: Causes

Ensuring consistent performance in lithium-ion batteries is crucial, especially for power wheel and motorcycle applications. Battery consistency encompasses

All You Need to Know About Li-ion Batteries

Mar 9, 2021 · Li-ion batteries have a voltage and capacity rating. The nominal voltage rating for all lithium cells will be 3.6V, so you need higher voltage

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · Accurately calculating the capacity of battery packs is of great significance to battery fault diagnosis, health evaluation, residual value assessment, and predictive

Impact of Individual Cell Parameter Difference

Abstract Lithium-ion power batteries are used in groups of series–parallel configurations. There are Ohmic resistance discrepancies, capacity

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Understanding aging mechanisms in lithium-ion battery packs

Mar 15, 2015 · However, engineering practice indicates that battery packs always fade more critically than cells. We investigate the evolution of battery pack capacity loss by analyzing cell

Understanding property variability of lithium-ion cells in

This study investigated the influence of natural cell-to-cell variability (CtCV) in capacity and internal resistance on the electrothermal behavior of lithium-ion battery modules composed of

Understanding Battery Basics: Chemistry,

Aug 14, 2025 · Batteries store chemical energy and convert it into electrical energy, powering countless devices from cars to laptops. Key concepts in

What does the consistency of lithium battery packs mean?

Through the research on the inconsistency of single cells in lithium-ion series-parallel combined batteries, SES Power analyzes that the main influencing factor in parallel battery packs is DC

What is Inconsistency in the Battery Packs? And

Nov 27, 2021 · The inconsistency of lithium-ion (li-ion) batteries is mainly manifested in two aspects: the difference in battery cell performance

The Significance of Cell Balancing in Lithium Packs

Apr 25, 2024 · The use of lithium-ion battery packs for storing energy generated from renewable sources, such as solar and wind power, is increasing. Cell

Understanding Lithium-Ion Battery Packs: A Beginner''s Guide

Aug 9, 2024 · A lithium-ion battery pack is a collection of individual lithium-ion cells grouped together to increase voltage and capacity. These packs are designed to store and deliver

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Learn the differences between battery cells, modules, and packs, and how they work together to power applications efficiently.

Experimental study on lithium-ion cell characteristics at

Jan 1, 2022 · Clarifying the relationship between the characteristics of lithium-ion battery and the discharge rate is beneficial to the battery safety, life and state estimation in practical

Study on battery pack consistency evolutions and equilibrium diagnosis

Dec 1, 2017 · The consistency among lithium-ion battery pack is an important factor affecting their performance. The paper analyzes the impact sensitivity of parameters consistency including

Influence of the connection topology on the performance of lithium

Sep 1, 2021 · In summary, the impact of parameter variations on the performance of battery packs with different topologies was widely published, from series to parallel, through statistical

Maximizing Shelf Life: Understanding Battery

Oct 11, 2023 · The ideal storage temperature range for lithium-ion batteries is typically between 0°C and 25°C (32°F and 77°F). Storing batteries within this

A modified reliability model for lithium-ion battery packs

May 31, 2019 · The reliability assessment of battery packs is an important topic in the reliability design of electric vehicles. To improve the accuracy of the reliability analysis, a modified

The composition, method and parameter

Nov 13, 2023 · The lithium-ion battery PACK technology is an essential component in the energy storage industry. Let''s explore some fundamental

Lithium-Ion Battery Packs for EVs

Jan 1, 2014 · Battery pack development for electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs) includes many of the same considerations involved in the development of

What You Need to Know About Lithium Ion

Jan 5, 2024 · Lithium-ion battery packs offer high energy density, providing more energy storage capacity compared to other battery types of similar size and

A study of cell-to-cell variation of capacity in parallel

Feb 1, 2021 · Lithium-ion batteries have been widely used in electrified vehicles, such as plug-in hybrid electric vehicles (PHEVs) and electric vehicles (EVs) [1], and renewable energy

Understanding Lithium-Ion Battery

Nov 13, 2024 · Discover the essential lithium-ion battery characteristics, including capacity, voltage, lifespan, and safety features. Learn why these batteries are

Use of a multiphysics model to investigate the performance

Jan 1, 2023 · Lithium-ion battery (LIB) packs are the most important key component of EVs, where multiple cells are connected in series and in parallel to achieve high power and large

Why Proper Cell Balancing is Necessary in

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very

Cell Replacement Strategies for Lithium Ion

Jul 23, 2020 · The second scenario for reuse of lithium ion battery packs examines the problem of assembling a pack for less-demanding applications

Battery Sorting & Capacity Checks in Lithium-ion

In lithium-ion batteries production, even slight variations can significantly impact performance. Capacity and sorting are crucial steps that guarantee consistent

Lithium Battery Pack: Types, Design, Safety, and

Jun 25, 2024 · Lithium battery packs have revolutionized the landscape of portable electronics and electric vehicles, offering advanced technology that

lithium ion

Apr 13, 2021 · When matching li-ion cells in a battery pack how do you use both the cell''s resistance AND capacity? I''ve seen sources mentioning that each parallel group should have

Mechanisms for the evolution of cell-to-cell variations and

Dec 1, 2024 · The increasing demand for green energy and power has significantly boosted the development of lithium-ion batteries (LIBs) for electric vehicles (EVs) and energy storage

The consistency of battery cells is important for

The inconsistency of the lithium-ion battery pack or the discrete phenomenon of the battery pack refers to the voltage, charge capacity, capacity, decay rate,

The Main Factors Determine The Capacity

Aug 5, 2024 · Achieving good capacity, state of charge, internal resistance, and self-discharge consistency is essential for maximizing and utilizing the battery

6 FAQs about [Does the capacity of lithium battery packs have to be consistent ]

Is battery capacity consistent with battery consistency trend?

The actual capacity was compared and found to be consistent with the battery consistency trend of capacity characterization. This method can quickly describe the battery pack consistency problem, and can be applied during the normal charging process of the battery pack.

Are lithium-ion batteries safe?

With the prevailing application of lithium-ion batteries, the durability and safety for battery packs receive more and more attentions from researchers and engineers since the improper usage of batteries will shorten the battery life , , , and even sometimes cause severe fire hazards , .

Does lithium iron phosphate battery capacity increase curve reflect consistency between monomers?

In this paper, the lithium iron phosphate battery capacity increase curve (IC curve) was used as an analysis tool. It is found that the IC curve characteristic peaks of different monomers in the battery pack can reflect the consistency between the monomers.

What is the inconsistency of battery capacity and internal resistance?

The inconsistency of the battery capacity, the internal resistance and the initial SOC of discharge is illustrated in Fig. 1. In this battery pack, the ratios of the range to mean value for the capacity, the internal resistance and the initial SOC of discharge are 16%, 21%, 34%, respectively.

What is the state of health of a lithium ion battery?

The state of health (SOH) of lithium-ion batteries is a comprehensive evaluation index of battery aging. The characterization and estimation of battery health status is the key technology of the new generation battery management system. Since the SOH

What is the nominal capacity of a battery pack?

The nominal capacity of the battery pack is 105Ah, three cells with nominal capacity of 35 A h in parallel constitute a battery module, and 104 battery modules are then serially connected composed of the battery pack. The bus is off grid when parked at night, and the battery pack are not be charged when standing by.

Industry Information

- Best lifepo4 power station factory Factory

- Is the energy storage sector the same as the wind solar and energy storage sector

- AC Purification Uninterruptible Power Supply

- Micro photovoltaic power generation and energy storage

- How many kilowatts of power should be selected for outdoor power supply

- Suriname energy storage battery brand ranking

- China high tension switchgear in Vietnam

- 12v5w solar water pump

- China on grid hybrid inverter in Canada

- High frequency ultra-high voltage inverter square wave

- Banjul rooftop photovoltaic panel light room

- 320kw inverter maximum input current

- Portugal solar power generation and energy storage manufacturers

- 220v450w portable power bank

- Atess hybrid inverter factory in Laos

- Romanian outdoor power supply lithium iron phosphate

- 24v portable ups uninterruptible power supply

- How to calculate the current from the battery cabinet voltage

- Which inverter manufacturer is the best for sale

- Tajikistan grid-connected to off-grid inverter

- Managua Photovoltaic Curtain Wall Project

- Battery energy storage system share of Croatian communication base stations

- Omega solar inverter in China in Mongolia

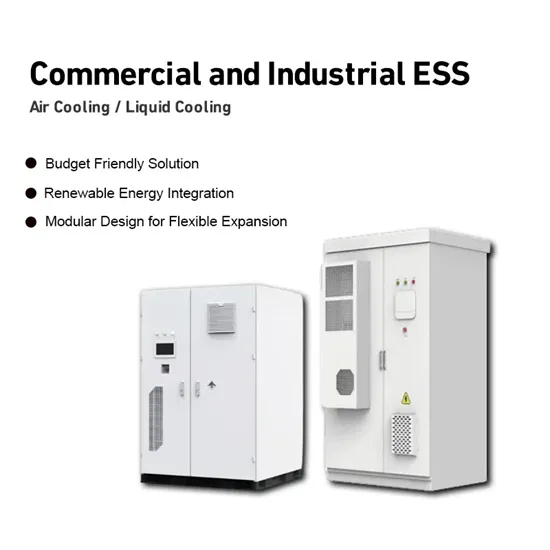

Commercial & Industrial Solar Storage Market Growth

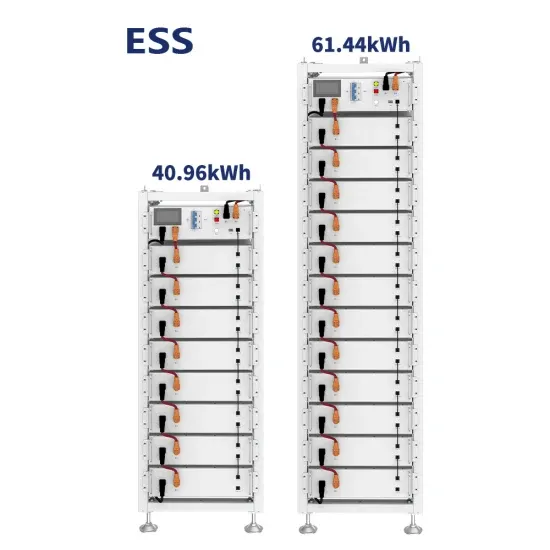

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

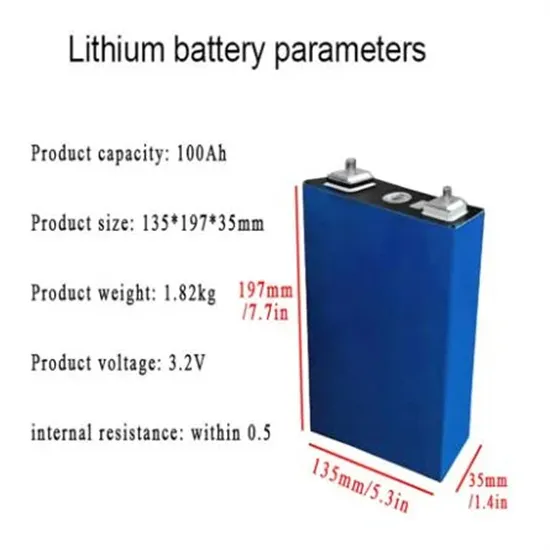

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.