A Polyolefin Elastomer Encapsulant Modified by

Jan 8, 2024 · In this study, a newly designed adhesion promoter, a modified ethylene–propylene–diene terpolymer (m-EPDM), was constructed via a

Recover value materials from waste photovoltaic modules as

Jan 1, 2025 · In the recovery of dual glass waste PV modules, chemical swelling dissociation has significant advantages. According to the results, DMC had excellent effect on the separation of

Photothermal Chemistry Based on Solar Energy

Nov 26, 2021 · Solar-driven chemistry is an attractive way to solve energy and environmental problems, among which photothermal chemistry (PTC) can

Green recycling of end-of-life photovoltaic modules via

Nov 1, 2024 · Sustainable End-of-life (EOL) photovoltaic (PV) modules recycling is essential for achieving resource conservation and alleviating environmental issues. Ethylene vinyle acetate

Investigating the Crosslinking, Degradation, and Adhesion

Dec 16, 2024 · Degradation of photovoltaic (PV) module encapsulant characteristics that lead to mechanical embrittlement and delamination remains a cause of failure in solar installations. A

표2

Reaction with glass and the gel state etching solution have for 30sec~120 sec. RTAG glass of PV cell cover glass is completed washing with distilled water and thoroughly dry the glass surface.

Study on the separation of crystalline silicon photovoltaic

Jun 1, 2025 · In chemical reaction processes, especially in mass transfer-controlled reactions, the ability of reagents to penetrate into the substance is a crucial factor affecting the reaction.

Reaction Mechanisms and Interfacial Behaviors

Aug 7, 2019 · Corrosion of silicate glasses in aqueous environment is common and it impacts many physical and chemical properties of these materials that

What is a photovoltaic cell in chemistry?

Sep 7, 2022 · How do you create a photovoltaic cell? A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material

Al3+ driven-hydrolysis of amide group presented in the

Jun 30, 2025 · For the interface transition zone (ITZ) between glass and EVA, the chemical bonding state of the molecular cross-linking bridge formed by the coupling agent was

A novel method for layer separation of photovoltaic

Mar 15, 2023 · With the number of lifespan-limited photovoltaic (PV) modules rising significantly, the recycling of scrapped PV modules containing valuable and hazar

Efficient decapsulation of waste PV modules

TGM, a novel chemical reagent system of decapsulation was firstly applied for environmentally friendly recycling of waste PV modules.

Performance study and environmental evaluation of alkali

Dec 15, 2022 · The above valid information once again shows that the use of waste photovoltaic glass in the development of AAM is of great significance to solve the two problems of global

A review of self-cleaning coatings for solar photovoltaic

Jul 27, 2023 · When sunlight shines on the photovoltaic panel, it needs to pass through the photovoltaic glass and encapsulant before reaching the photovoltaic cell. Therefore, for

Innovative recycling of end-of-life photovoltaic panels with

Recycling end-of-life photovoltaic (PV) panels is challenging, as multiple-layer structure makes separation and material recovery processes complex and resource-intensive. This study

The Use of Glass from Photovoltaic Panels at the End of

Nov 4, 2021 · The research has shown that it is possible to prepare cement composite based on recycled glass from solar panels, with compressive and flexural strength after 28 days

Life Cycle Assessment of Recycling Waste Glass from Retired

Jul 29, 2025 · As the cumulative waste of retired photovoltaic (PV) modules is projected to exceed 1 million tons by 2030, the resultant loss of silicon, glass, and valuable metals has become a

Chemical treatment of crystalline silicon solar cells as a

Aug 1, 2010 · Photovoltaic modules in crystalline silicon solar cells are made from the following elements, in order of mass: glass, aluminium frame, EVA copolymer transparent hermetising

Al3+ driven-hydrolysis of amide group presented in the

Jun 30, 2025 · Hydrometallurgical decapsulation has been considered an important recovery method due to energy saving and the ability to recover all components of photovoltaic

Acetic acid production and glass transition concerns with ethylene

Feb 15, 2007 · Photovoltaic (PV) devices are typically encapsulated using ethylene-vinyl acetate (EVA) to provide mechanical support, electrical isolation, and protection against environmental

Utilization of photovoltaic panels waste glass in high

Feb 8, 2021 · Specifically, this work investigates waste glass from photovoltaic panels, which is examined in terms of chemical composition, optimization of concrete mixture, experimental

Insights into the Encapsulation Process of Photovoltaic

Aug 14, 2024 · Samples of 5 mg of a During the PV module encapsulation complex chemical reactions are expected commercially available fast-cure EVA process a crosslinked polymeric

Experimental investigation on the combustion performance

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

표2

Reaction with glass and the gel state etching solution have for 30sec~120 sec. RTAG glass of PV cell cover glass is completed washing with distilled water and thoroughly dry the glass surface.

Enhancing anti-reflective properties of electronic glass

Jun 15, 2024 · The mentioned studies predominantly concentrated on the composition system of soda-lime glass, with limited research conducted on the anti-reflective properties of

Unraveling the pyrolysis behavior and co-pyrolysis

Jan 15, 2025 · However, beyond 465°C, the presence of residual backsheet materials alters the chemical environment of the reaction system, resulting in an inhibitory effect. These findings

The causes and effects of degradation of encapsulant

Jan 1, 2018 · The appearance of bubbles is usually due to chemical reactions that release gases, which typically appear at back of the module and accumulate in the encapsulant, but may

A comprehensive Review on interfacial delamination in photovoltaic

Jan 1, 2024 · Delamination at various interfaces in a PV module is a prevalent degradation mode that impacts long-term performance and reliability. To prevent or mi

6 FAQs about [Chemical reaction of photovoltaic glass]

How does glass improve photon absorption & conversion?

Advances in glass compositions, including rare-earth doping and low-melting-point oxides, further optimize photon absorption and conversion processes. In addition, luminescent solar concentrators, down-shifting, downconversion, and upconversion mechanisms tailor the solar spectrum for improved compatibility with silicon-based solar cells.

What is photovoltaic glazing?

The photovoltaic (PV) glazing technique is a preferred method in modern architecture because of its aesthetic properties besides electricity generation. Traditional PV glazing systems are mostly produced from crystalline silicon solar cells (c-SiPVs).

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

How tempered glass is used to generate solar power?

This solar power is being generated by converting sunlight into electricity through Photovoltaics (PV) which is also called as solar cells. Solar cells comprise of many parts from which tempered glass is the one whose high strength acts as a shield for the solar modules by protecting them from mechanical loads and extreme weather conditions.

What oxides are used in solar glass?

In solar glass formulations, the key compo- magnesium oxide (MgO). These oxides are widely used because of their abundant they provide to the glass matrix. process. The resulting glass exhibits the mechanical and optical properties necessary transmission, and thermal resistance. The predominant use of these basic oxides solar technologies.

Industry Information

- 5g base station electricity is very expensive

- 1 2 kw solar inverter factory in Nicaragua

- What are the global base station communication equipment

- The impact of 5G base station power equipment on line losses

- Ankara complete mobile energy storage power supply structure

- 12v to 220v inverter for sale in Vaduz

- Huawei inverter import price

- St George UPS Uninterruptible Power Supply Battery Company

- Guatemala City Solar Panel Assembly Factory

- What photovoltaic panels are used to generate electricity on islands

- Solar power satellite factory in Us

- Energy storage inverter supply

- High quality factory price furnace breaker for sale

- What are the specifications of photovoltaic panel columns

- Pyongyang rechargeable energy storage battery

- Make photovoltaic panels to generate electricity for home use

- Is the explosion-proof box for energy storage batteries useful

- Sf6 circuit breaker in hindi in Burundi

- East African energy storage container customization company

- How to connect UPS with multiple battery cabinets

- Energy storage battery container assembly method

- Which lithium battery is cheaper in Kuala Lumpur

- Number of photovoltaic cell modules connected in series and parallel

Commercial & Industrial Solar Storage Market Growth

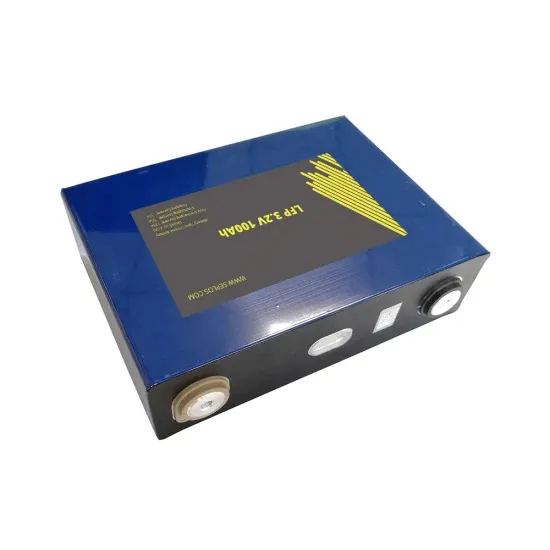

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.