BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · There are several interesting milestones to oversee when manufacturing a Battery Energy Storage Sys- tem: • Battery pack assembly and testing • PCS assembly and testing •

Container energy storage battery assembly method

What is a battery energy storage system? g containers, allowing for versatile deployment. When planning the implementation of a Battery Energy Storage System, policy makers face a range

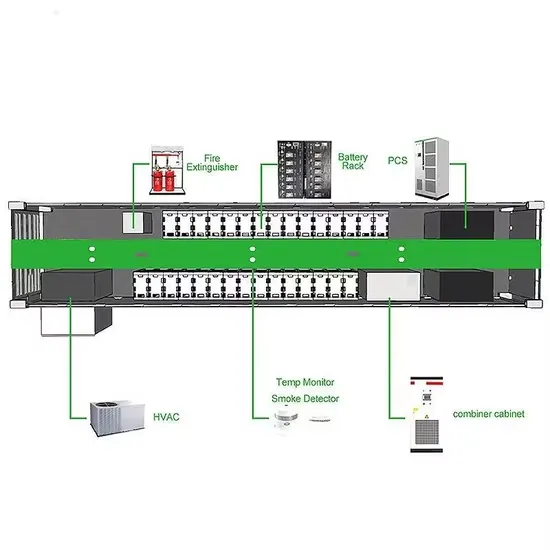

Detailed Understanding of the Containerized Battery System

Dec 13, 2024 · The containerized battery system has become a key component of contemporary energy storage solutions as the need for renewable energy sources increases. This system is

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Introduction: Due to the instability of photovoltaic power generation, energy storage battery Pack, as an efficient and flexible power

BMS, PCS, and EMS in Battery Energy Storage Systems

Jul 19, 2025 · Explore the essential components of Battery Energy Storage Systems (BESS): BMS, PCS, and EMS. Learn their functions, integration, and importance for efficient, safe

Battery Pack Assembly Process Series 9

Jun 12, 2025 · This issue will introduce in detail the basic knowledge about the specifications and dimensions of energy storage containers, transportation methods, code meanings, protection

5MWh Battery Storage Container (eTRON BESS)

This is a 45.8% increase in energy density compared to previous 20 foot battery storage systems. The 5MWh BESS comes pre-installed and ready to be

ETN News | Energy Storage News | Renewable

4 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

Overview of Battery Energy Storage (BESS) commercial

Sep 9, 2021 · Overview of Battery Energy Storage (BESS) commercial and utility product landscape, applications, and installation and safety best practices Jan Gromadzki Manager,

Energy Storage System

Aug 20, 2025 · Whole-life Cost Management Thanks to features such as the high reliability, long service life and high energy efficiency of CATL''s battery systems, "renewable energy + energy

The BESS System: Construction, Commissioning,

4 days ago · A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

What Is A Battery Container?

Nov 4, 2024 · Battery containers are large-scale, flexible energy storage systems housed in shipping containers, crucial for grid stabilization, renewable energy

HOW TO DESIGN A BESS (BATTERY ENERGY

Mar 11, 2023 · The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety,

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Understanding Battery Pack Technology: Key Components,

Mar 14, 2025 · Battery pack technology is a sophisticated system integrating battery cells, a battery management system (BMS), structural components, and thermal management

The Art and Science of Energy Storage Equipment Assembly:

Let''s face it – when most people hear "energy storage equipment assembly," they imagine technicians casually snapping battery modules together like LEGO bricks. But in reality, this

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

Intensium Energy Storage Systems | Saft

6 days ago · Saft, has extended its energy storage system (ESS) offering with the launch of its latest innovation: the Intensium® Flex (I-Flex) battery storage

Lithium battery energy storage cabinet assembly method

Our cutting-edge battery charger cabinets, seamlessly integrated within our Lithium-Ion Energy Storage Cabinet lineup, ensure secure and fire-resistant containment during battery charging.

Container Design for Battery Energy Storage

Aug 14, 2025 · Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient

Comprehensive Guide to Battery Assembly

Jun 18, 2024 · Battery assembly combines cells and connectors to create functional batteries. Using precise tools and steps ensures proper functionality

Container energy storage battery manufacturing process

A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechargeable batteries (storage devices) for later use. A battery is a

Full-scale walk-in containerized lithium-ion battery energy storage

Dec 1, 2022 · Three installation-level lithium-ion battery (LIB) energy storage system (ESS) tests were conducted to the specifications of the UL 9540A standard test method [1]. Each test

Battery Pack Assembly Process Series 7

Jun 6, 2025 · Installation process: Generally, the liquid cooling machine and the main liquid cooling pipe are installed first, and then the second and third level pipelines are installed. After

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The manufacturing quality of energy storage containers highly relies on precise and reliable equipment support - whether it is the production consistency of battery units, the

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy storage

Proper Grounding is Critical for Battery Energy

May 15, 2024 · For grid-scale battery energy storage systems (BESS), grounding and bonding is essential for safety and performance. The goal of grounding

Battery Pack Assembly Process Series 9

Jun 12, 2025 · Battery energy storage systems are mainly divided into: container energy storage, industrial and commercial energy storage, household energy storage and portable energy

Robust BESS Container Design: Standards-Driven

Jun 18, 2025 · A Battery Energy Storage System container is more than a metal shell—it is a frontline safety barrier that shields high-value batteries, power

CN116864854A

The invention discloses an energy storage battery container system and a control method of the energy storage battery container system, and relates to the technical field of electric energy

6 FAQs about [Energy storage battery container assembly method]

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

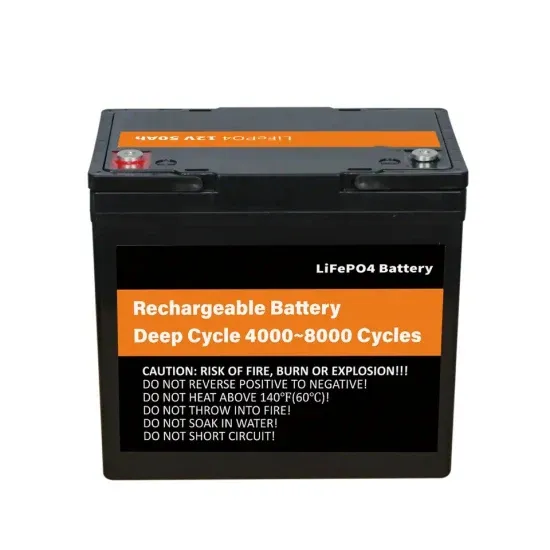

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

What is the production process for chisage ESS battery packs?

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly, pack testing, and packaging for storage. Now, following in the footsteps of Chisage ESS, our sales engineers are ready to take you on a virtual tour!

Industry Information

- Solar power satellite factory in El-Salvador

- Lobamba energy storage low temperature lithium battery

- Smart solar inverter in China in Sweden

- Huawei Portable Energy Storage Foundry

- Communication system base station

- Huawei Power System Energy Storage pAck Cooperation

- Xc90 high voltage inverter

- Maldives communication green base station room solution

- What is the spectrum range of flywheel energy storage in communication base stations

- Vanadium batteries for Cameroon energy storage power station

- Photovoltaic energy storage system villa

- Atess hybrid inverter factory in Uae

- Bangladesh communication base station flow battery module

- Roman Liquid Cooling Energy Storage

- How many square meters does solar energy have if it is 100 watts

- Double throw breaker in China in Niger

- Lome Photovoltaic Combiner Box Factory Direct Sales

- 4 2 kw solar inverter factory in Puerto-Rico

- Base station communication equipment power

- Huawei Mozambique Energy Storage Container

- How much does it cost to customize a containerized energy storage vehicle

- Voltage loss of photovoltaic panels

- Outdoor power cabinet design

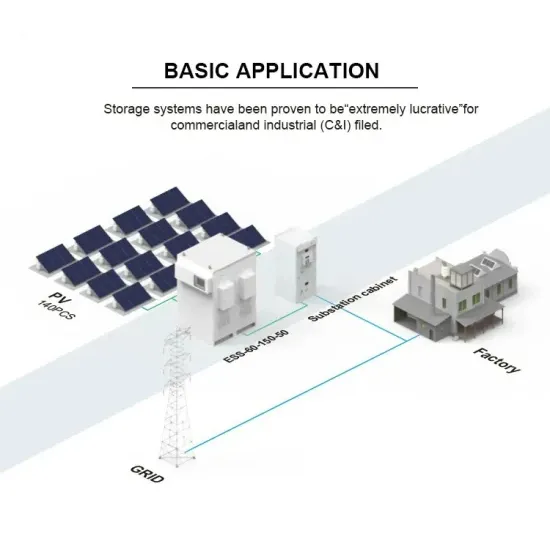

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.