A Review on Low-Temperature Performance Management of Lithium-Ion Batteries

Oct 26, 2023 · This review aims to resolve this issue by clarifying the phenomenon and reasons for the deterioration of LIB performance at low temperatures. From the perspective of system

NTC Thermistor Temperature Sensors Provide Li

NTC thermistor temperature sensors are a key component in Li-Ion battery charging and safety. They provide critical temperature data required to keep

Real-Time Prediction of Li-Ion Battery Pack

Mar 22, 2022 · To evaluate the thermal management system of a li-ion battery pack, the design of experiments (DOE) has to incorporate a range of

Low Temperature Lithium Ion Battery: 9 Tips for Optimal Use

Nov 6, 2024 · A low temperature lithium ion battery is a specialized lithium-ion battery designed to operate effectively in cold climates. Unlike standard lithium-ion batteries, which can lose

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Improving Temperature Measurement Accuracy in

Aug 14, 2023 · When a lithium-based battery operates outside of the cell manufacturer''s specified temperature range, there is a risk of thermal runaway occurring, which can ultimately result in

Reliable Battery Technology for Low Temperatures: -5°C to

Charging and discharging standard lithium batteries at extremely low temperatures (below 0°C/32°F) can result in lithium precipitation that can ultimately lead to battery pack fires or

Lithium Battery Performance at Low Temperature

The effects of low temperature on lithium ion battery performance and techniques to improve performance at these conditions.

Low-Temperature Cut-Off In Lithium Batteries

Oct 9, 2023 · Low-temperature cut-off (LTCO) is a critical feature in lithium batteries, especially for applications in cold climates. LTCO is a voltage

Large-capacity temperature points monitoring of lithium-ion battery

Mar 15, 2025 · At present, the application of FBG sensors in the temperature measurement of lithium-ion batteries is mostly focused on the embedded monitoring of a single cell, and there

Low-Temperature Performance Best Practices for Lithium Batteries

Jul 25, 2025 · Low-temperature performance is largely determined by electrolyte conductivity and solid electrolyte interface (SEI) stability. Modern additives (fluoroethylene carbonate, LiFSI)

Multi-Cell Battery Sensing and Protection IC With Integrated Low

Mar 26, 2025 · The demand for compact battery management systems (BMS) in applications such as two-wheelers and uninterruptible power supplies has driven the development of battery

Lithium Battery Operating Temperature: Min

Feb 22, 2024 · Learn the minimum and optimal temperature ranges for lithium batteries, and how cold weather affects performance and charging.

How does lithium battery BMS determine the

May 1, 2025 · Lithium battery BMS utilizes a high-precision sensor network to collect key parameters such as voltage, current, and temperature for each cell

Below -20℃ Low-Temperature Battery Pack in

Customized low-temperature battery packs with high capacity and long cycle life can be discharged at -40°C ~ 60°C and charged at -20°C~+55°C.

A low-temperature internal heating strategy without lifetime reduction

Nov 15, 2018 · To overcome the long-standing challenge of poor performance of large-size automotive lithium-ion battery pack at low temperature, an internal self-heating strategy

What voltage is too low for an AA battery? Minimum voltage

Sep 4, 2020 · A standard AA lithium (non-ion) battery is not intended to be rechargeable but they are powerful and very long-lasting cell type.?Lithium AA batteries?are perfect for more robust

Lithium-ion battery pack thermal management under high

Mar 1, 2024 · To ensure the stable operation of lithium-ion battery under high ambient temperature with high discharge rate and long operating cycles, the phase cha

Battery Pack Thermal Design

Aug 17, 2016 · Isothermal conduction calorimeters along with battery testers are best equipment to measure heat generation at various current rates, temperatures, and states of charge (SOCs)

Lithium-ion battery structure that self-heats at low

Jan 20, 2016 · Here we report a lithium-ion all-climate battery that very efficiently heats itself up in extremely cold environments by diverting current through a strip of metal foil to generate heat

Toward Low-Temperature Lithium Batteries

May 20, 2021 · Lithium batteries have been widely used in various fields such as portable electronic devices, electric vehicles, and grid storages devices.

Battery warm-up methodologies at subzero temperatures for

Mar 1, 2020 · Electric vehicles play a crucial role in reducing fuel consumption and pollutant emissions for more sustainable transportation. Lithium-ion batteries, as the most expensive

Cell Design for Improving Low-Temperature

Jul 10, 2023 · With the rapid development of new-energy vehicles worldwide, lithium-ion batteries (LIBs) are becoming increasingly popular because of their

How Heat Alters Lithium Battery Performance and Lifespan

May 27, 2025 · High temperatures affect lithium battery performance, lifespan, and safety by accelerating degradation and increasing risks. Learn how to manage these challenges.

A review on challenges in low temperature Lithium-ion cells

A comprehensive analysis reveals that both low and high-temperature extremes yield detrimental effects, with each temperature range presenting unique challenges that impact battery

Integrated All-Climate Heating/Cooling System

Oct 12, 2022 · The continuous low temperature in winter is the main factor limiting the popularity of electric vehicles in cold regions. The best way to solve this

Embedded internal temperature measurement of single Lithium

Jul 30, 2025 · In this paper, the temperature characteristics of lithium-ion power battery packs under different operating conditions are investigated, with special focus on the temperature

Real-Time Temperature Monitoring of Lithium

Apr 18, 2024 · Electrochemical energy storage stations serve as an important means of load regulation, and their proportion has been increasing year by

Critical Review of Temperature Prediction for

Nov 29, 2024 · This paper reviews recent advancements in predicting the temperature of lithium-ion batteries in electric vehicles. As environmental and

A Comprehensive Guide to the Low Temperature

Feb 22, 2024 · The low temperature li-ion battery solves energy storage in extreme conditions. This article covers its definition, benefits, limitations, and

Low temperature heating methods for lithium-ion batteries:

May 1, 2025 · However, such researches generally entail long industrialization cycles. On the contrary, the heating methods for power batteries are more suitable solution in the short term.

Using Thermistors to Enhance Thermal Protection for

Dec 23, 2023 · Battery chemistry is temperature-dependent, and operation outside its thermal range could lead to a reduction in battery life and performance over its life. Different battery

Battery Temperature

Sep 4, 2010 · Moreover, in a typical large lithium battery pack containing thousands of single lithium ion batteries, if the BMS detects a sharp rise in temperature, a large number of

Battery Pack Thermal Design

Aug 17, 2016 · Temperature Impact on LIB Lithium-ion batteries (LIB) are the technology of choice for many applications LIBs are sensitive to temperature as it impacts life, performance

A review of the estimation and heating methods

Mar 9, 2019 · Although some relative topics, such as the effect of cold temperature in Li-ion batteries, modeling a Lithium-ion battery, and heating

Thermal management of 21700 Li-ion battery packs

Jan 5, 2024 · Lithium-ion batteries (LiBs) are excellent selection for the energy storage in electric vehicles (EVs) because they have great energy and power density, long lifetime, low self

Low-Temperature Performance of Lithium-Ion Batteries for

Jul 25, 2025 · Macroscopically, the low-temperature performance of lithium-ion power batteries is manifested as an increase in the battery''s impedance with decreasing temperature, a

Novel approach for liquid-heating lithium-ion battery pack

Sep 15, 2023 · The charging time for Li-ion power battery in hybrid electric vehicles (HEVs) and pure electric vehicles (EVs) is elongated at low temperature compare

6 FAQs about [Low temperature measures for lithium battery pack]

What is a low temperature lithium ion battery?

A low temperature lithium ion battery is a specialized lithium-ion battery designed to operate effectively in cold climates. Unlike standard lithium-ion batteries, which can lose significant capacity and efficiency at low temperatures, these batteries are optimized to function in environments as frigid as -40°C.

Can lithium-ion batteries be managed at low temperatures?

The management of low-temperature lithium-ion batteries is examined. An exhaustive overview of the challenges encountered by lithium-ion batteries at low temperatures. Assessment and discourse on whole-cell low-temperature methodologies and proposed future development.

What is a low temperature internal heating strategy for lithium-ion battery pack?

A low temperature internal heating strategy with AC+DC for lithium-ion battery pack. The permissible AC and DC are determined to circumvent lithium-ion deposition. A simple soft-switching circuit with low loss is designed for heating battery pack. The essentially uniform temperature distribution within battery pack during heating.

How do you store low temperature lithium ion batteries?

Proper storage is crucial for maintaining the integrity and performance of low temperature lithium-ion batteries: Cool and Dry Environment: Store these batteries in a controlled environment away from extreme heat or moisture to prevent degradation.

What is low-temperature cut-off (LTCO) in a lithium battery?

Low-temperature cut-off (LTCO) is a critical feature in lithium batteries, especially for applications in cold climates. LTCO is a voltage threshold below which the battery’s discharge is restricted to prevent damage or unsafe operation.

How to heat a lithium-ion battery pack?

An effective yet simple soft-switching circuit is designed for heating of large-size automotive lithium-ion battery pack. The battery pack is warmed up from −20.8 °C to 2.1 °C within 600 s, where the temperature difference among twelve batteries is below 1.6 °C, implying the essentially uniform temperature distribution.

Industry Information

- Charge and discharge of flow battery

- Where is the inverter for the 5g communication base station in Estonia

- China 2400W portable power station company

- Top Ten Systems of Wind Turbines

- SataEK tool battery

- Solar photovoltaic panels produced in Botswana

- Castries is full of communication base station battery energy storage systems

- New Zealand Auckland Multifunctional Energy Storage Power Company

- Small solar inverter in China in Switzerland

- Does energy storage power station use lithium

- Sf6 circuit breaker in China in Atlanta

- Ghana 7w photovoltaic panel price

- Energy storage system charges the grid

- Containerized energy storage system solution

- Huawei Belmopan Outdoor Power Supply Factory

- Plant top solar photovoltaic panels

- Outdoor base station wind power technical specifications and standards

- Urban and rural base station communication maintenance

- West Asia Industrial Energy Storage Manufacturer

- Amman New Energy Photovoltaic Site Energy

- Huawei Lithuania Home Energy Storage

- Recommended outdoor power supply for monitoring

- Tokyo Solar Photovoltaic Panel Sales

Commercial & Industrial Solar Storage Market Growth

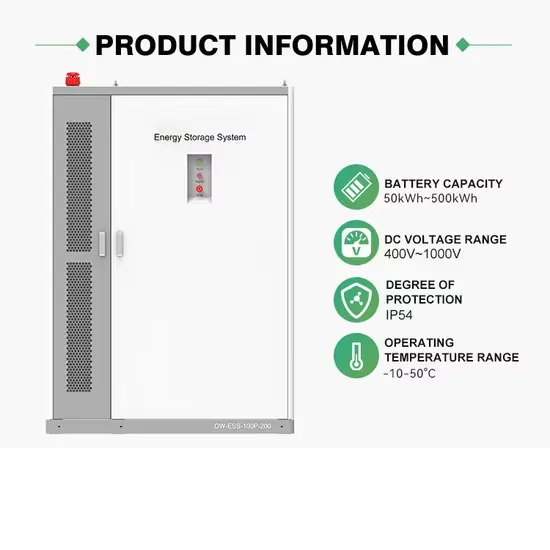

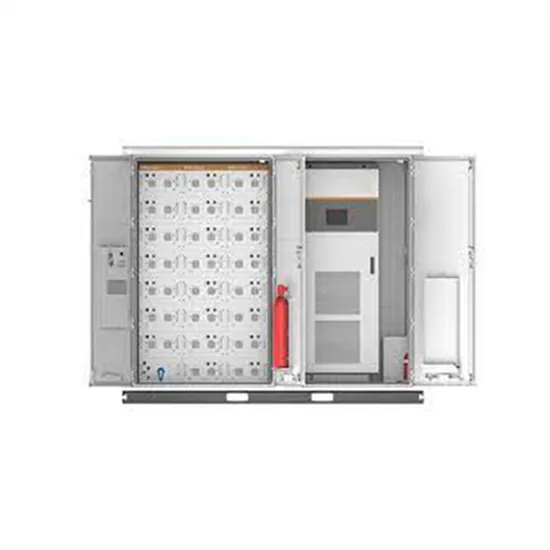

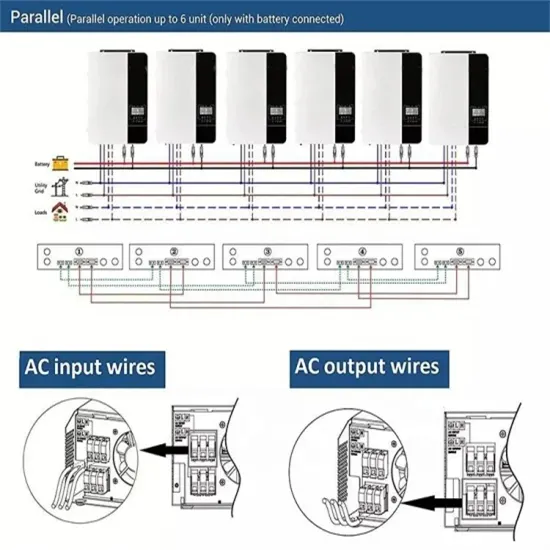

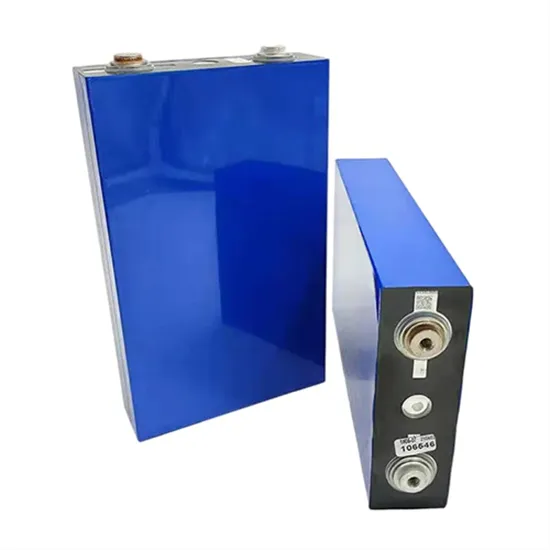

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.