Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The present study aims to address this research gap by providing a temporal analysis of aluminum and glass intensity in crystalline silicon modules produced from 2006 to

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Monocrystalline silicon solar cells are more efficient than polycrystalline silicon solar cells in terms of power output. In order to increase

Project news: Prototypes of crystalline silicon based modules

Jun 30, 2017 · Operational c-Si based module prototypes One of the main BIPV market acceptability constrains is that most crystalline photovoltaic solutions show visible cell busbars

CRYSTALLINE SILICON PHOTOVOLTAIC GLASS

2 days ago · Crystalline silicon photovoltaic glass is recognized for its superior energy output, yielding more energy than amorphous silicon glass under direct

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Effectively and completely separating the waste crystalline silicon

Jun 22, 2025 · Among various PV modules, crystalline silicon occupies more than 90 % of the market share due to its high power conversion efficiency, good environmental stability, and

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

CRYSTALLINE SILICON PHOTOVOLTAIC MODULES WITH

Jul 25, 2008 · Flash test results taken under Standard Test Conditions (1000 W/m2, AM1.5G spectrum, 25° C) for the modules made using the Vendor #1 AR coated glass are shown in

Research Assistant

Aug 12, 2025 · The complete photovoltaic glass and crystalline silicon cell have high economic value, so how to selectively remove EVA film and fluoride backplate is an important step in the

Comparative Life Cycle Assessment of Crystalline Silicon Glass

Jun 10, 2022 · A comparative life cycle assessment between plastic PV modules and conventional crystalline silicon glass-sheet based PV modules, shows environmental benefits f

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Folder1_Page1.CDR

May 21, 2021 · HighestQualityWorldwide BISOL PRODUCTS BISOL produces high quality mono- and multicrystalline silicon photovoltaic modules designed for both commercial and residential

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · Crystalline silicon solar cells are widely used in solar cells due to the mature technology. Its share in the solar cell market accounts for more than 95 % (Benda, 2018;

Crystalline Silicon Module

5.4 Photovoltaic modules There are various module technologies currently deployed in agrivoltaic systems. The major market share of modules consists of crystalline silicon modules.

Crystalline Silicon Photovoltaic Modules, Crystalline Silicon

Unlike thin-film technologies like CdTe or CIGS, crystalline photovoltaic cells are made from crystalline silicon, the same material commonly used in traditional solar panels. When applied

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The silicon energy bandgap determines the ultimate efficiency of PV cells made from c-Si; this value is 29.4%. As already explained in Section 8.4.2, c-Si solar cells have to be

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Glass Application in Solar Energy Technology

Apr 28, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and

Overview of global status and challenges for end-of-life crystalline

Jun 1, 2021 · Recent developments in photovoltaic (PV) technology have enabled a reduction of fossil fuel usage and subsequent carbon dioxide (CO 2) release from energy production.

Crystalline Silicon Solar Cell

2.1 Crystalline silicon solar cells (first generation) At the heart of PV systems, a solar cell is a key component for bringing down area- or scale-related costs and increasing the overall

Crystalline silicon photovoltaic modules with anti-reflective coated glass

Jan 7, 2005 · Abstract: This paper reports on a set of experiments to determine what efficiency gain can be achieved by using AR coated glass and to evaluate the weatherability of the

Crystalline Silicon Terrestrial Photovoltaic Cells

4 days ago · Executive Summary This study report documents the need for a supply chain procurement specification and standard that applies to photovoltaic (PV) cells. Many PV

Crystalline Silicon PV Module Technology

Jan 1, 2013 · Wafer-based crystalline silicon (c-Si) solar cells require serial interconnection and packaging to render a product with reasonable voltage for outdoor use. This task is

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Lamination process and encapsulation materials for

May 21, 2024 · Introduction The majority of today''s crystalline silicon (c-Si) PV modules are manufactured in accordance with a glass-backsheet (GBS) module lay-up: 3.2–4mm glass at

Delamination of components for recovery of waste crystalline

Jan 15, 2025 · Generally, crystalline silicon PV panels are composed of PV modules and metallic frames. PV modules are formed by lamination of tempered glass, solar cells, ethylene–vinyl

Crystalline Silicon Photovoltaics

Mono-crystalline silicon solar cells have higher efficiencies than multi-crystalline silicon solar cells. In crystalline silicon photovoltaics, solar cells are generally connected together and then

The research progress on recycling and resource utilization

Jun 15, 2024 · Komoto et al. [32] asserted that the recycling objectives for crystalline silicon photovoltaic modules involve the separation and recovery of glass, silicon cells, and other metals.

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · NREL Photovoltaic Module Reliability Workshop February 16, 2011 Photovoltaic Glass Technologies Corning has a long history of life-changing innovations Glass envelope for

Crystalline Silicon PV Module Field Failures

Jan 1, 2019 · Typical crystalline PV modules are composed of front glass (sometimes transparent fluoropolymers), encapsulant (majority is EVA, other less popular encapsulants include PVB,

Development of lightweight and flexible crystalline silicon

Oct 15, 2023 · Abstract Lightweight and flexible solar cell modules have great potential to be installed in locations with loading limitations and to expand the photovoltaics market. We used

(PDF) Crystalline Silicon Solar Cells: State-of-the

Jun 17, 2012 · The cost distribution of a crystalline silicon PV module is clearly dominated by material costs, especially by the costs of the silicon wafer.

AMORPHOUS SILICON PHOTOVOLTAIC GLASS

2 days ago · Amorphous silicon photovoltaic glass features a thin, uniform layer of silicon between two glass panels, allowing light to pass through due to its

Robust crystalline silicon photovoltaic module (c-Si PVM) for

Jul 1, 2020 · Interconnection technologies employed in the manufacture of crystalline silicon photovoltiac (c-Si PV) module are reviewed for application in the manufacture of robust

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

6 FAQs about [Sukhumi crystalline silicon photovoltaic module glass]

What is crystalline silicon photovoltaics?

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si). These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

What type of glass is used for solar panels?

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable, weather resistant photovoltaic modules. The glass type that can be used for this technology is a low iron float glass such as Pilkington Optiwhite™.

What is the conversion efficiency of crystalline silicon heterojunction solar cells?

Masuko, K. et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 4, 1433–1435 (2014). Boccard, M. & Holman, Z. C. Amorphous silicon carbide passivating layers for crystalline-silicon-based heterojunction solar cells. J. Appl. Phys. 118, 065704 (2015).

Could low-bandgap thin-film solar cells kill crystalline silicon PV technology?

Eventually, the combination of high-bandgap and low-bandgap thin-film solar cells (such as perovskite/perovskite) could combine high efficiency and low cost, spelling the death of crystalline silicon PV technology.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

Is there a new LCI for crystalline silicon PV systems?

In late 2020, IEA PVPS released an updated LCI for PV systems that contains updates for crystalline silicon PV technology reflecting the year 2018, while some information, such as the amounts of auxiliary materials, are still based on 2011 .

Industry Information

- How many photovoltaic panels are needed to generate 3 kilowatts of electricity

- Togo s new energy storage requirements

- Solar energy on site works 24 hours

- House inverter system factory in Hungary

- Finland Flexible Container Wholesale

- Production of simple lithium battery pack

- Berlin Energy Storage Lithium Battery Price

- Guatemala City lithium battery pack custom manufacturer

- How many kilowatts does a solar panel generate

- High quality factory price solar powerbox Wholesaler

- Modular energy storage power station battery compartment installation

- Outdoor prefabricated cabin energy storage system

- Power management system for Hargeisa base station

- San Salvador Air Energy Storage Power Station

- Photovoltaic power station inverter

- Ups lithium iron phosphate battery station cabinet

- Photovoltaic glass composition lithium

- What are the special batteries for household energy storage in St Petersburg Russia

- Factory price 110 amp breaker in Guinea

- Application prospects of energy storage power stations

- Does the capacity of lithium battery packs have to be consistent

- Solar 220V power generation system

- Solar Inverter Quote

Commercial & Industrial Solar Storage Market Growth

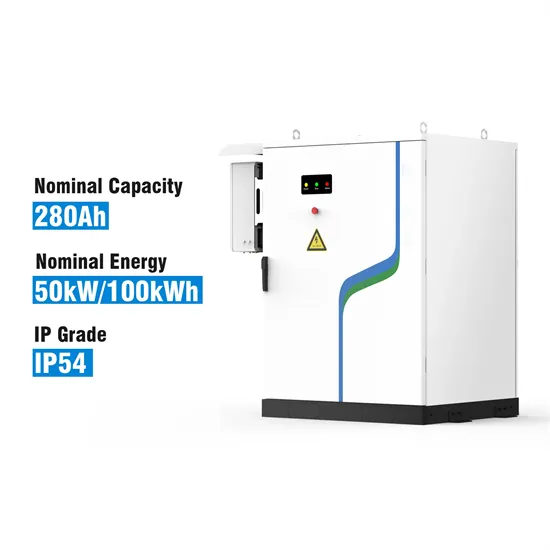

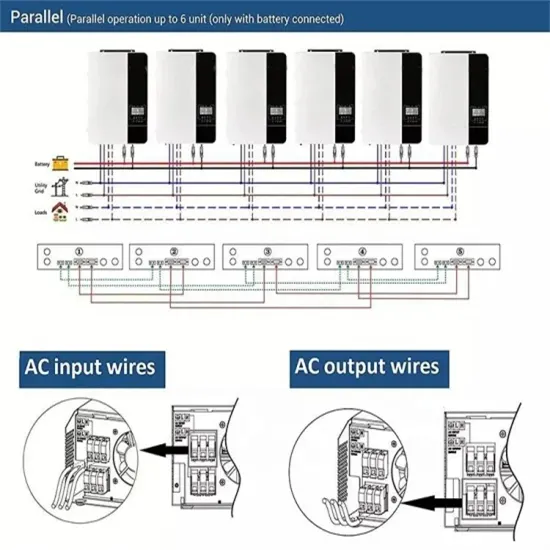

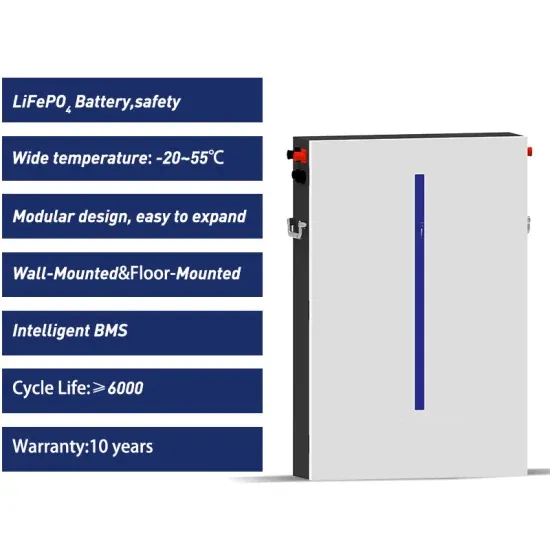

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.