Monocrystalline solar panels: the expert guide

Jul 25, 2025 · Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more

Monocrystalline solar panels – Uses, Benefits

Apr 17, 2024 · Monocrystalline solar panels are photovoltaic panels manufactured from a single silicon crystal. They are common for domestic and business

High-efficiency monocrystalline silicon single-sided half-chip

High-efficiency Monocrystalline Silicon Single-sided Half-chip Solar Module 425-565wp Photovoltaic Solar Panel, Find Complete Details about High-efficiency Monocrystalline Silicon

Comprehensive Guide to Monocrystalline Solar Panel

Mar 5, 2023 · Related Article: Monocrystalline VS Polycrystalline Solar PV Modules How do Monocrystalline Solar Panels Work? Monocrystalline solar panels transform sunlight into

What is Monocrystalline Solar Panel: A Consolidated Guide

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Explanation of the principle of monocrystalline silicon

Monocrystalline solar cells are solar cells made from monocrystalline silicon, single-crystal silicon. Monocrystalline silicon is a single-piece crystal of high purity silicon. It gives some exceptional

550w Solar Power Panel Monocrystalline Silicon 182 Multigrid Single

550w solar power panel monocrystalline silicon 182 multigrid single glass half chip module off-grid photovoltaic panels

Design and Implementation of an Automatic Single Axis Solar Tracking

Aug 7, 2021 · The power consumption rate is increasing daily, and people are greatly dependent on conventional energy sources. If it continues, the conventional energy sources will end very

Monocrystalline vs Polycrystalline Solar Panels

Jun 5, 2024 · In terms of photovoltaic solar panels, monocrystalline and polycrystalline panels are the two most common options. Both incorporate

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

Types of photovoltaic solar panels and their

Nov 6, 2017 · Photovoltaic solar panels are devices specifically designed for the generation of clean energy from sunlight. In general, photovoltaic panels are

Monocrystalline silicon | Solar Galaxy | 1300 339 596 | Single

Jul 5, 2025 · In the realm of solar energy, monocrystalline silicon is preferred for photovoltaic cells due to its ability to convert more sunlight into electricity compared to polycrystalline silicon

Monocrystalline Silicon

20.3.1.1 Monocrystalline silicon cells Monocrystalline silicon is the most common and efficient silicon-based material employed in photovoltaic cell production. This element is often referred

sunhero

Discover the differences between monocrystalline and polycrystalline solar panels, including their efficiency, appearance, and suitability for various applications.

Single-chip polycrystalline silicon solar panels

Monocrystalline, Polycrystalline, and Thin-Film: A Comparison Monocrystalline panels use single-crystal silicon. They offer high efficiency and long lifespans but cost more than other types.

Jinko Solar Panels Monocrystalline silicon Single-Sided Half-Chip

Jinko Solar Panels Monocrystalline Silicon Single-sided Half-chip Solar Photovoltaic Modules 555w 560w 565w 570w 575w - Buy Jinko 555w 560w 565w 570w 575w Pv Panels Mono-facial

High quality 360w multifunctional single-sided monocrystalline

High quality 360w multifunctional single-sided monocrystalline half-chip solar photovoltaic panel mobile power supply

Jinko Solar Panels Monocrystalline silicon Single-Sided Half-Chip

Jinko Solar Panels Monocrystalline silicon Single-Sided Half-Chip Solar Photovoltaic Modules 555w 560w 565w 570w 575w, You can get more details about Jinko Solar Panels

Crystalline Silicon Photovoltaics Research

3 days ago · DOE supports crystalline silicon photovoltaic (PV) research and development efforts that lead to market-ready technologies.

What is Solar Module? Types of Solar Modules

3 days ago · What is Solar Module? A single photovoltaic Module/Panel is an assembly of connected solar cells that will absorb sunlight as a source of

What chips do solar panels need? | NenPower

Oct 6, 2024 · In the solar energy industry, the effectiveness and efficiency of photovoltaic (PV) systems rely heavily on the quality and type of chips utilized

What Is A Monocrystalline Solar Panel? | Definition, Cost,

Feb 11, 2025 · A monocrystalline solar panel is a type of photovoltaic (PV) panel constructed from a single, continuous silicon crystal. This distinguishes them from polycrystalline panels, which

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

What are monocrystalline solar panels?

Jun 15, 2025 · What are monocrystalline solar panels? Monocrystalline solar panels are a type of solar panel design that uses a single silicon crystal to capture sunlight and generate energy.

Monocrystalline Silicon

Monocrystalline Silicon: Single-Crystal Silicon Plays A Crucial Role In Solar Panels By Efficiently Converting Sunlight Into Electricity Production Process of Monocrystalline Silicon

What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · Monocrystalline solar panels, known as mono panels, are a highly popular choice for capturing solar energy, particularly for residential

Monocrystalline Solar Panels: Advantages and

As the name implies this type of solar panel are unique in their use of a single, very pure crystal of silicon. Using a process, similar to making semi

Monocrystalline Solar Panels: Maximizing

Mar 5, 2023 · Monocrystalline solar panels are made up of high-purity silicon crystals and have a single, uniform structure. This unique structure makes

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · Monocrystalline solar panels, also known as single crystalline solar panels, are made from a single continuous crystal structure. These panels are manufactured using high

Things You Need to Know About Monocrystalline Solar Panels

Jul 26, 2025 · The single crystal structure ensures robust panel construction, making them less susceptible to damage caused by external factors such as temperature fluctuations, hail, or

6 FAQs about [Single-chip monocrystalline photovoltaic panel]

What are monocrystalline solar panels?

Monocrystalline solar panels, known as mono panels, are a highly popular choice for capturing solar energy, particularly for residential photovoltaic (PV) systems. With their sleek, black appearance and high sunlight conversion efficiency, monocrystalline panels are the most common type of rooftop solar panel on the market.

Are monocrystalline photovoltaic panels a good choice?

Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are considered an excellent choice for anyone wishing to install a high quality photovoltaic system, whether for residential or industrial use.

How many solar cells are in a single monocrystalline panel?

Based on their size, a single monocrystalline panel may contain 60-72 solar cells, among which the most commonly used residential panel is a 60-cells. Features A larger surface area due to their pyramid pattern. The top surface of monocrystalline panels is diffused with phosphorus, which creates an electrically negative orientation.

Should you switch to monocrystalline solar panels?

Additionally, they reported instances where home owners have had to rip up all their thin film panels and sell those at a loss in order to boost the size of their solar power system when they switched over to monocrystalline solar cells to produce more electricity as their usage increased over the years.

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

Industry Information

- 2080wp photovoltaic panel size

- Is there any battery cabinet replacement in Kigali

- Guyana s largest photovoltaic energy storage company

- San Jose Outdoor Energy Storage Power Distributor

- Special inverter minimum voltage 3v

- High-pressure flywheel energy storage

- Energy storage charging and discharging solutions

- Majuro Emergency Lighting Lithium Battery Pack

- High quality 220 gfci breaker in Philippines

- Tajikistan 48v inverter

- Solar power storage for sale in Auckland

- Fire protection acceptance standards for energy storage battery cabinets

- Reducing the voltage of photovoltaic panels

- Honduras grid-connected inverter manufacturer brand

- What is solar cell shingling

- Dushanbe outdoor power supply 220v

- Factory grid-connected inverter installation

- Can new energy battery cabinets withstand pressure

- Taipei Energy Storage Lithium Battery

- Companion 40ah power station in France

- Side energy storage battery

- Energy storage equipment profit

- What is the use of energy storage vehicle batteries

Commercial & Industrial Solar Storage Market Growth

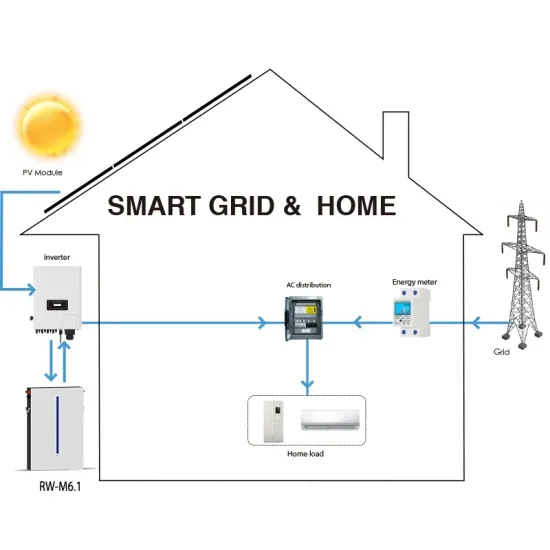

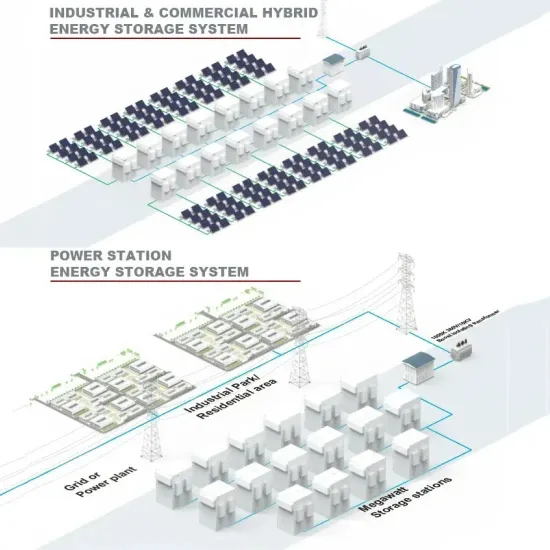

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

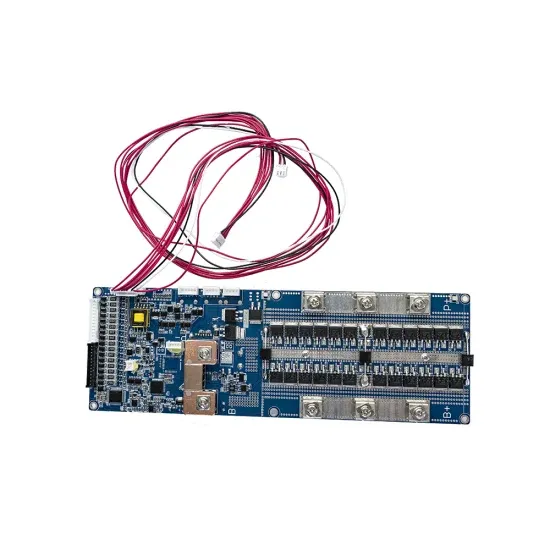

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.