What is a shingled solar cell

Shingling solar cells follow similar processed as in solar roof shingles.They are made by cutting a full-size solar cell into 6 equal strips. These cell strips are then assembled and overlaid, like

Schematic diagram of photovoltaic cell shingling principle

The diagram illustrates the conversion of sunlight into electricity via semiconductors,highlighting the key elements: layers of silicon,metal contacts,anti-reflective coating,and the electric field

Silver-free intrinsically conductive adhesives for shingled solar cells

May 15, 2024 · Solar cells shingled with PEDOT:PSS-based ICAs have similar photovoltaic performance metrics to those shingled with commercially available silver-based ECAs, as well

Solar cell shingling technical indicators

This paper reports on the latest advances in passivated emitter and rear cell (PERC)-based shingled solar cell activities at Fraunhofer ISE. The approach taken is to fabricate 6" host

The principle of monocrystalline silicon solar panel

Monocrystalline silicon is a single-piece crystal of high purity silicon. It gives some exceptional properties to the solar cells compared to its rival polycrystalline silicon. A single

What is Customized Small Size Shingling Solar Panel with Overlap Cells

What is Customized Small Size Shingling Solar Panel with Overlap Cells for Solar Roof Tile, 9bb solar panel manufacturers & suppliers on Video Channel of Made-in-China .

What does photovoltaic panel shingling mean

Shingled solar panels should not be confused with solar shingles used in photovoltaic energy applied to construction (see figure 3). As already mentioned,solar shingles are nothing more

Solar cells used in photovoltaic shingling technology

ABSTRACT: This work discusses challenges and advantages of cut solar cells, as used for shingling and half-cell photovoltaic modules. Cut cells have generally lower current output and

Performance of shingled solar modules under

Nov 8, 2021 · Schematic drawing of the two shingling approaches (A) string-type in which n serial-interconnected shingle solar cells form m parallel

What is Solar Cell Soldering Machine Spraying Type Shingling

What is Solar Cell Soldering Machine Spraying Type Shingling Stringer, Shingled string welding machine manufacturers & suppliers on Video Channel of Made-in-China .

What are Shingled Solar Panels? Everything You Should Know!

Oct 5, 2023 · Shingled Solar Cells –The Trending PV-Technology True shingled solar cells have no visible busbars. They are cut into five or six strips and connected with an electrically

The Evolution of Shingled-Cell Solar Panels: Advantages Over

Sep 9, 2024 · Unlike traditional solar modules, which rely on larger, intact cells connected by visible busbars, shingled panels employ a unique cell arrangement that boosts performance

Shingled Solar Panels: Higher Power Output and

Shingling is a highly innovative technique that offers great potential for achieving significant cell-to-module (CTM) gains in solar panels. This approach

What Is Photovoltaic Shingled Technology?

Oct 28, 2024 · What Is Photovoltaic Shingled Technology?Traditional module packaging technology uses solder ribbons as a connection tool for cells. Due

Shingled Solar Panels Explanation – Everything

Namib150 Teflon and 240 Teflon Shingled Solar Panels New Namib150 Teflon and 240 Teflon Shingled Solar Panels Product Highlights Highly efficient

What''s good about shingled solar panels?

Mar 30, 2022 · Shingled or Overlapping Cell Technologies? Shingled solar panels or overlapping cells is an area where several rival producers are attempting,

What is High Efficiency Shingled Mono Cell 150W 1000V

What is High Efficiency Shingled Mono Cell 150W 1000V Portable Shingling Solar Moduel Folding Solar Panel with Compact Design for Extended Outdoor, Onsite Product Video manufacturers

Shingled Solar Cells

Aug 1, 2022 · Shingling solar cells follow similar processed as in solar roof shingles. They are made by cutting a full-size solar cell into 6 equal strips.

Shingled solar panels | Alternergy

Jun 22, 2023 · Shingled Cell Technology In recent years, the market for solar modules significantly changed from more or less exclusively ribbon-based

What''re Shingled Solar Panels? What Benefits Do They Offer?

Sep 1, 2018 · Shingling technology is an extremely interesting development of cell interconnection in a photovoltaic module due to higher power densities at the same or lower cost, and

PERC-based shingled solar cells and modules at

May 21, 2024 · Solar cell shingling, an approach first introduced in the 1950s, targets the reduction of CTM losses mainly by: 1) eliminating the cell spacing through the overlapping of

CHALLENGES AND ADVANTAGES OF CUT SOLAR CELLS FOR SHINGLING

Can cut solar cells be used for shingling and half-Cell photovoltaic modules? ABSTRACT: This work discusses challenges and advantages of cut solar cells, as used for shingling and half

What is a shingled monocrystalline solar panel

Shingle solar cells are solar cells which are cut into typically 5 or 6 strips. These strips can be overlaid, like shingles on a roof, to form the electrical connections.

What is Mechanical Positioning High Temperature Solar Cell Shingling

What is Mechanical Positioning High Temperature Solar Cell Shingling Machine, Shingled string welding machine manufacturers & suppliers on Video Channel of Made-in-China .

Shingled solar modules and shading

Nov 18, 2021 · Scientists at Germany''s Fraunhofer Insititute for Solar Energy Systems (ISE) evaluated the performance of its newly introduced ''Matrix''

What is the principle of cell shingling technology

What is shingling technology? Shingling technology is an extremely interesting development of cell interconnection in a photovoltaic module due to higher power densities at the same or

Silver-free intrinsically conductive adhesives for

May 15, 2024 · The accelerated growth of solar photovoltaics needed to reduce global carbon emissions requires an unsustainable amount of silver. Here,

Shingle Solar Cells and Modules

To make solar modules as efficient as possible, the photoactive area must be maximized and the power loss must be minimized. The technique of laying out

What Are Shingled Solar Panels and How Do They Work

Jul 3, 2025 · Shingled solar panels use thin strips that overlap. These strips are solar cells. They collect sunlight and make electricity. Shingled solar panels are not the same as solar shingles.

CHALLENGES AND ADVANTAGES OF CUT SOLAR CELLS FOR SHINGLING

Can cut solar cells be used for shingling and half-Cell photovoltaic modules? ABSTRACT: This work discusses challenges and advantages of cut solar cells, as used for shingling and half

What is a shingled solar cell? | NenPower

Apr 18, 2024 · What you refer to as shingled solar cells represents an innovative approach in photovoltaic technology that enhances efficiency and

Solar cells used in photovoltaic shingling technology

As of now, the two most common types of solar cell technologies utilized in solar shingle manufacturing are crystalline-silicon-based (c-Si) cells and copper indium gallium selenide

Schematic diagram of photovoltaic cell shingling principle

What is a solar cell diagram? The diagram illustrates the conversion of sunlight into electricity via semiconductors,highlighting the key elements: layers of silicon,metal contacts,anti-reflective

6 FAQs about [What is solar cell shingling]

What is solar shingling & how does it work?

The technique of laying out solar cells in a module so that their edges overlap like shingles on a house roof is called »shingling« With the shingled layout, there are fewer gaps between the individual solar cells so more of the sunlight that is incident on the module can be absorbed.

How are shingling solar cells made?

Shingling solar cells follow similar processed as in solar roof shingles. They are made by cutting a full-size solar cell into 6 equal strips. These cell strips are then assembled and overlaid, like roof shingles, into longer strings of up to 40 cells depending on the panel size.

What are shingled solar modules?

A solar panel manufacturing process that has gotten some traction recently is “shingling.” Not to be confused with “solar shingles” used in building-applied photovoltaics, shingled modules cut solar cells into strips and overlap them inside the framed module.

What are solar shingles?

Solar shingles are essentially roof shingles or tiles made of solar cells, which serve the purpose of absorbing solar radiation to generate electricity but also perform as the structural support for your house roof. They are considered part of building-integrated photovoltaics.

Are shingled solar panels a structural component?

On the other hand, shingled solar panels do not act as a structural component of your roof. The interconnection of this technology consists of cutting solar cells into a certain number of strips which are overlaid by connecting their edges using an electrically conductive adhesive (ECA).

What is shingled solar cell technology?

The shingled cell technology is compatible with the more traditional silicon cell technologies such as all-black, half-cut, PERC, HJT and so on and can be found adapted to those configurations. For now, this still emerging technology represent the highest limit of traditional undoped crystalline silicon solar cell development so far.

Industry Information

- Construction technology of supercapacitors for communication base stations

- 455wp specification photovoltaic panel

- Energy storage cabinet intelligent manufacturing battery price

- China Ministry of Industry and Information Technology Communications 5G Base Station

- 15kWh large outdoor power supply

- Wholesale 5kwh battery backup in Bolivia

- Tunisia Photovoltaic Energy Storage Project

- Disadvantages of current lithium battery energy storage systems

- The most advanced energy storage product currently

- Glass photovoltaic ratio

- The largest energy storage photovoltaic power station in Pretoria

- Power plant battery energy storage frequency regulation

- Factory price bus tie breaker in Melbourne

- Advantages of building photovoltaic curtain wall

- 320kW photovoltaic inverter

- Solar lamp home energy saving foldable

- Sodium ion energy storage photovoltaic

- China Mobile 5G base stations and hybrid energy sharing

- Which is the best low-carbon photovoltaic curtain wall in Myanmar

- Bangi Distributed Energy Storage System

- How many volts is the grid-connected inverter

- Lithium iron phosphate energy storage battery modification

- Tunisia energy-saving energy storage equipment

Commercial & Industrial Solar Storage Market Growth

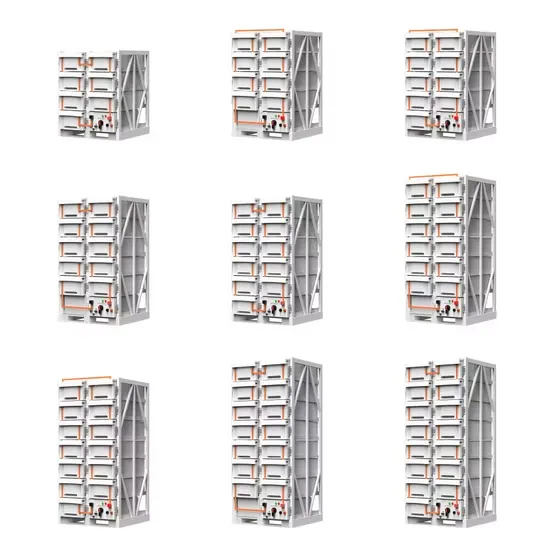

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

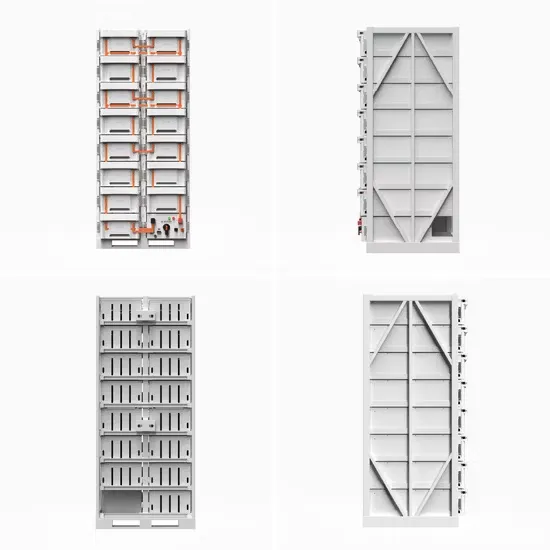

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.