Lithium manganese iron phosphate (LiMn1

Jun 9, 2025 · The growing demand for high-energy storage, rapid power delivery, and excellent safety in contemporary Li-ion rechargeable batteries (LIBs) has

Current research status on the structural

Aug 22, 2024 · With the current global economy developing at a rapid pace, research into lithium-ion batteries has become a focal point in many major

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Based on the prototype design of high-energy-density lithium batteries, it is shown that energy densities of different classes up to 1000 Wh/kg can be realized, where lithium-rich

Lithium Iron Phosphate (LiFePO4): A

Nov 20, 2024 · Lithium iron phosphate (LiFePO4) is a critical cathode material for lithium-ion batteries. Its high theoretical capacity, low production cost,

Modification Strategies for Enhancing the

Apr 7, 2025 · In recent years, lithium manganese iron phosphate (LiMn x Fe 1–x PO 4, LMFP) has attracted considerable interest, primarily because of its high

4 Reasons Why We Use Lithium Iron Phosphate Batteries in a Storage

Sep 30, 2024 · Discover 4 key reasons why LFP (Lithium Iron Phosphate) batteries are ideal for energy storage systems, focusing on safety, longevity, efficiency, and cost.

A Comprehensive Evaluation Framework for Lithium Iron Phosphate

Nov 29, 2024 · Abstract Lithium iron phosphate (LFP) has found many applications in the field of electric vehicles and energy storage systems. However, the increasing volume of end-of-life

A review of the Doping Modification of LiFePO4 as a

Nov 18, 2020 · Lithium iron phosphate (LiFePO4) has attracted wide attention in the field of large-capacity power lithium-ion batteries for its advantages of good stability, low raw material cost

Overview of Preparation Process of Lithium Iron

Jul 16, 2024 · Finally, we look forward to the development of lithium iron phosphate batteries and provide views on future new energy vehicle batteries.

A review of the Doping Modification of LiFePO4 as a

Nov 18, 2020 · In the today that energy crisis and the rapid development of electronic equipment, lithium-ion batteries, as a kind of energy storage device with high energy density, safe and

Journal of Energy Storage

Aug 1, 2024 · How to economically, efficiently, and stably synthesize various high-performance lithium-ion phosphate batteries suitable for different scenarios is currently one of the hot topics

Using Recovered Lithium Iron Phosphate Battery Materials as

Jun 7, 2025 · Li ion battery waste is an emerging environmental issue. This work demonstrates that lithium iron phosphate cathode material can be recovered from spent Li ion batteries and

Research on the Modification of Lithium Iron Phosphate

However, traditional lithium-based battery systems still face challenges such as energy density bottlenecks, insufficient cycle stability, and cost pressure. This study focuses on lithium iron

Research progress in lithium manganese iron phosphate

Zhipeng WEN, Kai PAN, Yi WEI, Jiawen GUO, Shanli QIN, Wen JIANG, Lian WU, Huan LIAO. Research progress in lithium manganese iron phosphate cathode material modification [J].

Exploring sustainable lithium iron phosphate cathodes for Li

Transformation of lithium, iron, and phosphorus ores into battery-grade precursors. Key steps in purification and refining processes. Overview of sustainable purified phosphoric acid

Everything You Need to Know About LiFePO4 Battery Cells: A

Apr 18, 2025 · Lithium Iron Phosphate (LiFePO4) battery cells are quickly becoming the go-to choice for energy storage across a wide range of industries. Renowned for their remarkable

Research on the Modification of Lithium Iron Phosphate

Jul 24, 2025 · This study focuses on lithium iron phosphate cathode materials, systematically exploring their crystal structure characteristics, electrochemical mechanisms, and modification

A review of the Doping Modification of LiFePO4 as a

Dec 1, 2020 · In the today that energy crisis and the rapid development of electronic equipment, lithium-ion batteries, as a kind of energy storage device with high energy density, safe and

Research on the Modification of Lithium Iron Phosphate

Jul 24, 2025 · Lithium-ion batteries have dominated in fields such as electric vehicles, intelligent terminals, and grid energy storage due to their advantages of high energy density, long cycle

Recent Advances in Lithium Iron Phosphate Battery

Dec 1, 2024 · Lithium iron phosphate (LFP) batteries have emerged as one of the most promising energy storage solutions due to their high safety, long cycle life, and environmental friendliness.

Recent advances in synthesis and modification strategies for lithium

Sep 15, 2024 · Abstract Lithium-ion rechargeable batteries are regarded as the most favorable technology in the field of energy storage due to their high energy density with the global

(PDF) Recent Advances in Lithium Iron Phosphate Battery

Dec 1, 2024 · Abstract Lithium iron phosphate (LFP) batteries have emerged as one of the most promising energy storage solutions due to their high safety, long cycle life, and environmental

High-energy-density lithium manganese iron phosphate for lithium

Jan 1, 2025 · The soaring demand for smart portable electronics and electric vehicles is propelling the advancements in high-energy–density lithium-ion batteries. Lithium manganese iron

Lithium Iron Phosphate and Layered Transition

Aug 23, 2023 · Lithium-ion batteries have gradually become mainstream in electric vehicle power batteries due to their excellent energy density, rate

Review on Defects and Modification Methods of

Jan 19, 2022 · However, as a result of the low conductivity of lithium iron phosphate and the slow diffusion rate of lithium ion, the development of lithium

Recycling of spent lithium iron phosphate battery cathode

Oct 5, 2024 · Under favorable conditions, the installed base of lithium iron phosphate (LFP) batteries exceeded that of ternary batteries, regaining the mainstream market position due to

Research progress of lithium iron phosphate in lithium-ion batteries

Jul 8, 2024 · <p>Currently, the Earth''s limited resources, the escalating oil crisis, rapid industrial development, and considerable population growth have increased the demand for sustainable

Lithium iron phosphate with high-rate capability synthesized

Dec 10, 2023 · Abstract Lithium iron phosphate (LiFePO 4) is one of the most important cathode materials for high-performance lithium-ion batteries in the future due to its high safety, high

The origin of fast‐charging lithium iron

Jan 10, 2022 · The origin of the observed high-rate performance in nanosized LiFePO 4 is the absence of phase separation during battery operation at high

Sustainable and efficient recycling strategies for spent lithium iron

Jun 22, 2025 · Lithium iron phosphate batteries (LFPBs) have gained widespread acceptance for energy storage due to their exceptional properties, including a long-life cycle and high energy

Exploring a sustainable and eco-friendly high-power

Mar 30, 2024 · The mounting waste generated by lithium iron phosphate (LFP) batteries has led to apprehensions regarding the depletion of resources, environmental pollution, and potential

Toward Sustainable Lithium Iron Phosphate in

May 20, 2024 · Abstract In recent years, the penetration rate of lithium iron phosphate batteries in the energy storage field has surged, underscoring the

Research on the Modification of Lithium Iron Phosphate

Jul 24, 2025 · W. Liu et al., Research Progress on the Modification of Lithium Iron Phosphate Cathode Material. Energy Storage Sci. Technol. 11, 467-486 (2022) [Google Scholar]

Navigating battery choices: A comparative study of lithium iron

Dec 1, 2024 · This research offers a comparative study on Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) battery technologies through an extensive m

Research progress in LiFePO<sub>4</sub> cathode

Lithium-ion batteries (LIBs), as secondary batteries, have rapidly developed into mainstream energy storage devices in the field of new energy. Lithium iron phosphate (LiFePO 4) is

6 FAQs about [Lithium iron phosphate energy storage battery modification]

Is lithium manganese iron phosphate a potential cathode material for next-generation lithium-ion batteries?

This review focuses on the structure and performance of lithium manganese iron phosphate (LMFP), a potential cathode material for the next-generation lithium-ion batteries (LIBs). How modifications like exotic element doping, surface coating, and material nanostructuring enhance its electrochemical properties are studied.

Is lithium iron phosphate a good energy storage cathode?

Since Padhi et al. reported the electrochemical performance of lithium iron phosphate (LiFePO 4, LFP) in 1997 , it has received significant attention, research, and application as a promising energy storage cathode material for LIBs.

What is lithium iron phosphate (LiFePO4)?

Lithium iron phosphate (LiFePO4) has attracted wide attention in the field of large-capacity power lithium-ion batteries for its advantages of good stability, low raw material cost and environmental friendliness, and is considered to be one of the most potential lithium-ion battery cathode materials.

What is lithium iron phosphate battery?

Lithium iron phosphate battery has a high performance rate and cycle stability, and the thermal management and safety mechanisms include a variety of cooling technologies and overcharge and overdischarge protection. It is widely used in electric vehicles, renewable energy storage, portable electronics, and grid-scale energy storage systems.

Can lithium iron phosphate cathode materials be modified?

To address energy attenuation and short circuits of lithium iron phosphate cathode materials during cycling, researchers have explored various strategies for modifying lithium iron phosphate [27, 28, 29, 30].

Can lithium iron phosphate batteries be reused?

Recovered lithium iron phosphate batteries can be reused. Using advanced technology and techniques, the batteries are disassembled and separated, and valuable materials such as lithium, iron and phosphorus are extracted from them.

Industry Information

- Microgrids and off-grid energy storage systems

- Customs declaration for battery cabinet

- Israel Energy Storage Products

- How much does it cost to generate photovoltaic power with energy storage in Abkhazia

- Solar powered house generator in Nicaragua

- Wholesale price of 5v photovoltaic panels in Hamburg Germany

- Industrial Energy Storage Project in Sao Paulo Brazil

- Wholesale 220v power station in Gabon

- Tg-box850w ups uninterruptible power supply

- Factory price thermal breaker in Karachi

- Look at the UPS battery cabinet base station

- Palau EK PV Inverter

- Electricity cost of various energy storage methods

- Actual power consumption of high frequency inverter

- Honiara Cabinet Energy Storage System Features

- Does the outdoor power supply need a battery

- Which battery cabinet is cheap and easy to use

- Laayoune large energy storage battery magnetic pump

- Portable power supply manufacturer in Mexico

- Indonesian energy storage power wholesale price

- Ye Photovoltaic Solar Panel Manufacturer

- What are the energy storage crystalline silicon batteries

- Energy storage cabinet battery foreign-funded enterprises

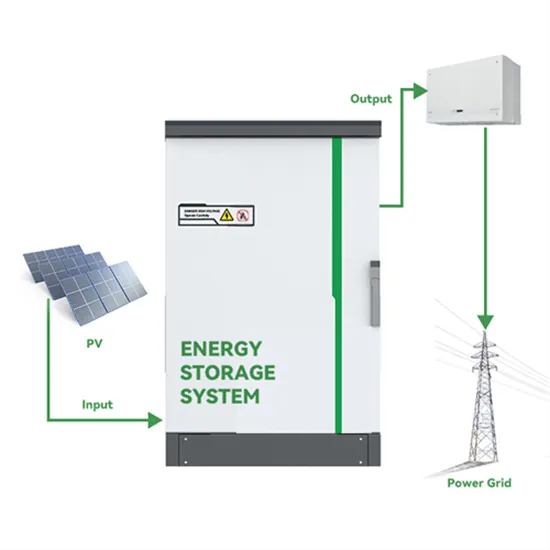

Commercial & Industrial Solar Storage Market Growth

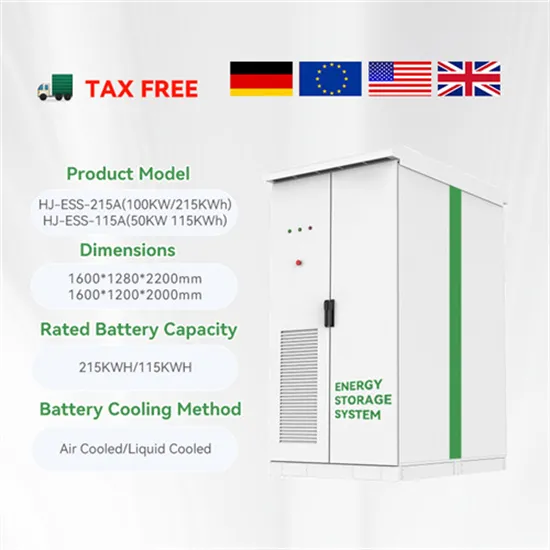

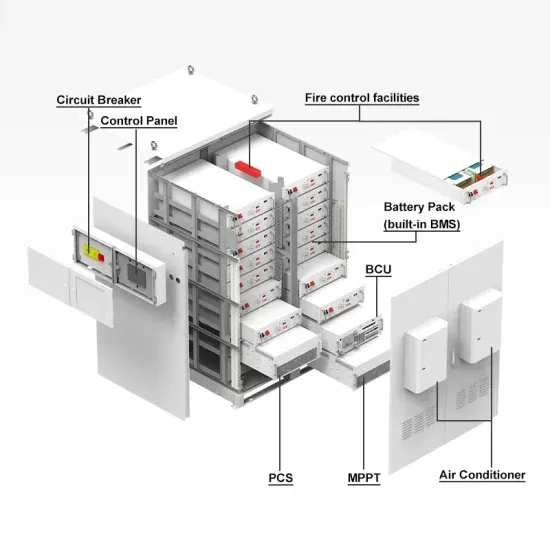

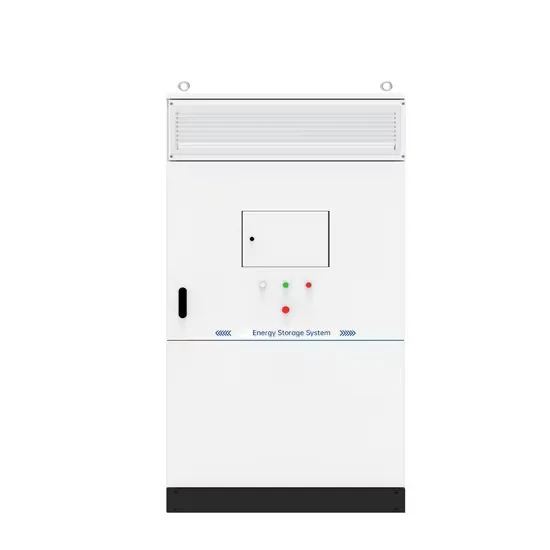

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

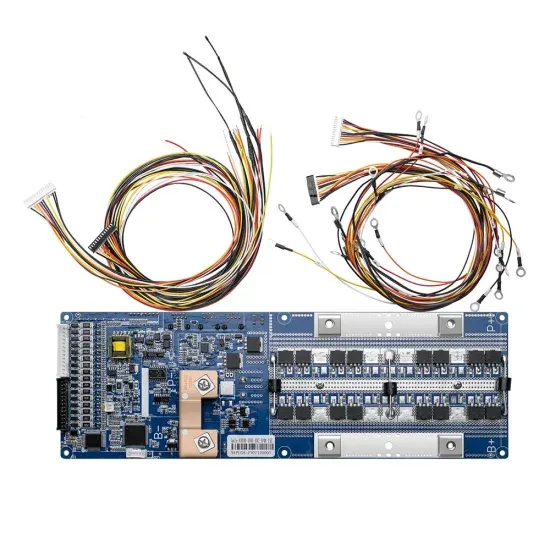

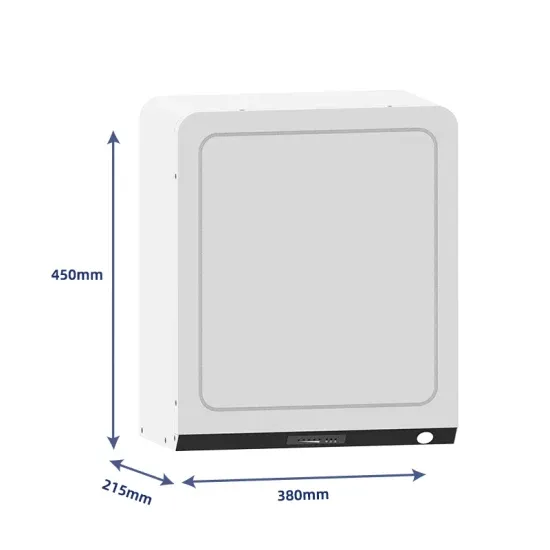

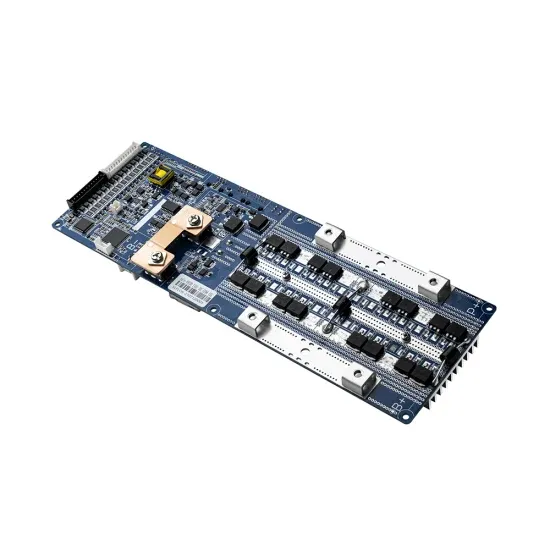

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.