Immersion liquid cooling for electronics: Materials, systems

Feb 1, 2025 · The current work systematically reviews the research progress on immersion cooling technology in electronic device thermal management, including the properties of

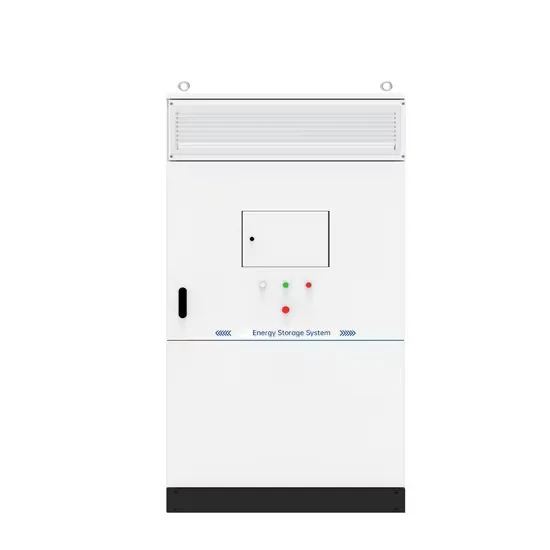

LIQUID COOLING ENERGY STORAGE SYSTEM

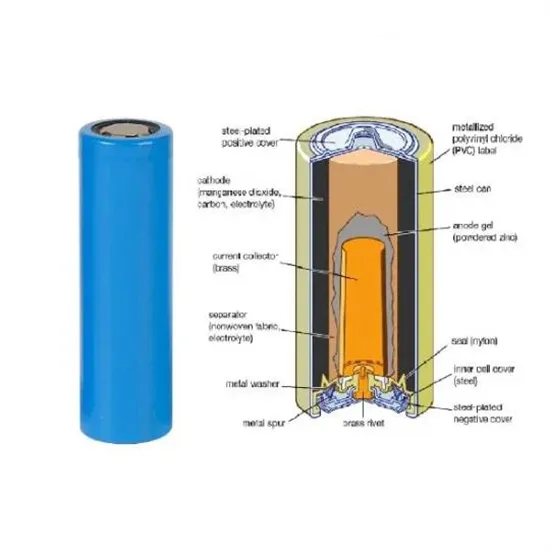

Jun 26, 2024 · The 100kW/230kWh liquid cooling energy storage system adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS

Liquid Cooling System Design, Calculation, and

Aug 19, 2025 · Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Meanwhile, in view of the insufficient energy-saving potential of the existing liquid cooled air conditioning system for energy storage, this paper introduces the vapor pump heat

liquid cooling energy storage system

Among various energy storage systems, liquid cooling energy storage stands out for its efficiency, reliability, and scalability, garnering increasing attention. The

Understanding battery liquid cooling system

5 days ago · The battery liquid cooling system has high heat dissipation efficiency and small temperature difference between battery clusters, which can improve

5.01MWh User Manual for liquid-cooled ESS

Jan 9, 2025 · dard Liquid-cooled Energy Storage System. Before using this product, please be sure to read this manual carefully and operate the energy storage system according to the

20ft 2MWh Outdoor Liquid-Cooling Energy

Aug 12, 2025 · The 20ft 2MWh outdoor liquid cooled energy storage container:Advanced thermal management,weatherproof design.Ideal for

A comprehensive review on sub-zero temperature cold thermal energy

Apr 15, 2021 · A comprehensive review on sub-zero temperature cold thermal energy storage materials, technologies, and applications: State of the art and recent developments

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Understanding Coolant Distribution Units

Understand the role of coolant distribution unit (CDUs) for liquid cooling and its ability to support higher heat densities in the data center environment.

Energy Storage System (ESS) Liquid Cooling

4 days ago · Liquid Cooling Chiller For Energy Storage Cabinet & Charging Pile >Liquid Cooling Chiller for Energy Storage Systems(ESS) Due to the

Coolant Distribution Units (CDU = water-cooling

CDUs are said to be the mainstream of cooling systems in the near future. In general, cooling systems with heatsinks, fans, air-conditioning units, etc. are

CEGN | Centralized Liquid-Cooled Energy

CEGN''s Centralized Liquid-Cooled Energy Storage System: Enhanced Efficiency, Safety, and Reliability CEGN''s Centralized Liquid-Cooled Energy Storage

LIQUID COOLING ENERGY STORAGE SYSTEM

Jun 26, 2024 · Product Introduction The 100kW/230kWh liquid cooling energy storage system adopts an "All-In-One" design concept, with ultra-high integration that combines energy

Liquid Cooling for Energy Storage—— Selection

Aug 19, 2025 · The isothermal liquid cooling plate for energy storage batteries is a heat dissipation technology applied to energy storage batteries. It can

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · 1. Short heat dissipation path, precise temperature control Liquid-cooled systems utilize a CDU (cooling distribution unit) to directly introduce low-temperature coolant into the

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance

Liquid Cooling Energy Storage System Design: The Future of

May 18, 2025 · Now imagine scaling that cooling magic to power entire cities. That''s exactly what liquid cooling energy storage system design achieves in modern power grids. As renewable

20ft 2MWh Outdoor Liquid-Cooling Energy

Aug 1, 2025 · The 20ft 2MWh outdoor liquid cooled energy storage container is composed of 7 1P416S, 1331.3V 280Ah battery racks with BMS, which has the

customized large scale liquid cooled energy

6 days ago · Containerized Liquid-cooling Energy Storage System represents the cutting edge in battery storage technology. Featuring liquid-cooling DC battery

Energy storage comparison of sorption systems for cooling

Jan 1, 2001 · A comparison between different sorption systems (binary mix only) such as absorption, adsorption and solid/gas reaction is presented with relation to their storage

Liquid Cooling Energy Storage System Composition

There are three options available for the storage of energy on a large scale: liquid air energy storage (LAES), compressed air energy storage (CAES), and pumped hydro

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · To achieve superior energy efficiency and temperature uniformity in cooling system for energy storage batteries, this paper proposes a novel indirect liquid-cooling system based

Energy storage liquid cooling system composition

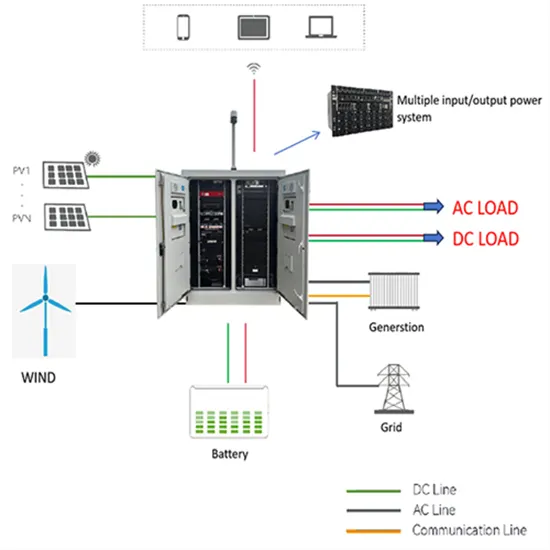

Aug 24, 2024 · The energy storage liquid cooling system is mainly composed of a liquid cooling unit, a liquid cooling plate, a circulation pipeline, and a quick-connect plug. In the liquid cooling

Structural composition of liquid-cooled energy storage

The key system structure of energy storage technology comprises an energy storage converter (PCS), a battery pack, a battery management liquid cooled energy storage cabinet adopts

Battery Liquid Cooling System Overview

1 day ago · In the future, as battery energy density and charging/discharging speeds continue to increase, liquid cooling technology will show even greater

CubeArk-Liquid Cooling 3.354Mwh 5.015Mwh Continer

Jul 16, 2024 · All-round real-time monitoring and energy optimization management, fully guarantee the safety of the battery system. Multiple working modes, suitable for various

Thermal Management of Liquid-Cooled Energy

Dec 13, 2024 · Compared to traditional air-cooling systems, liquid-cooling systems have stronger safety performance, which is one of the reasons why

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Discover how liquid cooling enhances energy storage systems. Learn about its benefits, applications, and role in sustainable power solutions.

Disrupting Data Centre Design

Jul 31, 2025 · It is a system and an ecosystem comprising various components such as Coolant Distribution Units (CDUs), cold plates, manifolds, liquid-cooled servers, heat rejection units,

EMW series liquid cooling unit for energy

Battcool-C series air cooled chiller for energy storage container is mainly developed for container battery cooling in the energy storage industry. It is

20ft 2MWh Outdoor Liquid-Cooling Energy

The 20ft 2MWh outdoor liquid cooled energy storage container is composed of 7 1P416S, 1331.3V 280Ah battery racks with BMS, which has the characteristics

6 FAQs about [Energy storage liquid cooling unit composition]

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

Industry Information

- 100 square meters photovoltaic module price

- Information required for energy storage cabinet export

- Tunisian high frequency inverter brand

- DC high voltage inverter capacitor

- Huawei Rural Energy Storage New Energy

- Are communication base station batteries energy storage batteries

- Solar panel 30 watts

- Montevideo Photovoltaic Container Substation

- High frequency square wave of inverter

- Does a high-power inverter consume electricity

- How to do charging and discharging experiment in battery cabinet

- Outdoor power supply self-operated sine wave

- Are there any solar air conditioners for sale in Bolivia

- Belize Wind and Solar Energy Storage Power Station

- Base station 48 volt power supply

- 5kw luxpower inverter factory in Brisbane

- Different voltage inverter selection

- Dublin Solar PV Energy Storage Company

- Togo Photovoltaic Communication Mobile Battery Cabinet

- Generator inverter manufacturers

- Maseru Energy Storage Photovoltaic Engineering Unit

- Kabul three-phase inverter manufacturer

- Outdoor power supply capacity price

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.