Battery Charging Cabinet Experiment Report Summary

In this study the analysis of charge and discharge characteristics of a commercial Li-ion battery is performed under C-rate 0.136 to 0.9 C in order to study the effects of undercharging on

Calculation methods of heat produced by a

Dec 1, 2018 · Lithium‐ion batteries generate considerable amounts of heat under the condition of charging‐discharging cycles. This paper presents quantitative

Battery Charging & Discharging: 10 Key

Mar 19, 2025 · Confused about battery performance? We break down 10 vital battery charging and discharging parameters. Optimize your battery life today!

Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

DC Lab

3 days ago · In this hands-on electronics experiment, you will build capacitor charging and discharging circuits and learn how to calculate the RC time

An experimental study on the charging and discharging

To understand the working characteristics of Li-ion battery and evaluate its performance of application on electric vehicles, charging and discharging experiments of Li-ion battery were

How rechargeable batteries, charging, and

May 31, 2025 · How rechargeable batteries, charging, and discharging cycles work The battery stores electrical energy in form of chemical energy and the

Capacitor Charging & Discharging: Physics Lab

Explore capacitor charging and discharging with this Engineering Physics II lab experiment. Measure voltage, calculate charge, current, and time constant.

Getting Started with Your First Experiment: Cyclic Charge

Sep 5, 2022 · The purpose of this test is to apply a constant current to batteries, super capacitors, or electrode materials in order to charge and discharge between defined voltage limits.

Understanding the Basics about Discharging in Batteries

Jul 22, 2025 · Basics about Discharging covers how batteries release energy, the discharge process, and key factors that impact battery performance and lifespan.

Charging and Discharging of Capacitors

Mar 8, 2024 · / Here t is the time, V0 is the effective battery voltage, τ is the time constant and t0 the adjusted starting time of the charging process. These three parameters are adjusted by

A Review on Battery Charging and Discharging

Apr 23, 2018 · Energy storage has become a fundamental component in renewable energy systems, especially those including batteries. However, in

Integrated Solar Batteries: Design and Device Concepts

The solar battery charging and discharging mechanism is comparable to BCH and BAH solar batteries discussed above; however, the charge storage mechanism deviates significantly: no

Explain Charging and Discharging of Lithium-Ion

Feb 7, 2025 · Learn how lithium-ion batteries charge and discharge, key components, and best practices to extend lifespan. Discover safe charging

Capacitor charging and discharging experiment design

arging and discharging of a capacitor Objectives: 1. The objective of this experiment is to verify the exponential behavior of apacitors during charging and discharging processes. Theory:

Experiment 7: RC Circuits

Nov 18, 2019 · The time dependence of the potential di erence V(t) for the charging and discharging process is shown in Figure 2. The time constant can be determined by observing

Analysis and detection of charge and discharge

Nov 4, 2023 · In the normal environment and high-temperature environment, the charging and discharging time meets the experimental requirements, and the two batteries have good

Measurement of battery energy storage cabinet

High temperatures when the power is charged and discharged will produce high temperatures during the charging and discharging of batteries.

Charging and Discharging Capacitors

Jun 30, 2016 · In this experiment you will study a parallel plate capacitor and determine the dielectric constant for paper. A capacitor is an electric device that stores charge. Capacitors

Battery Lab Manual

Charging a battery increase the state of charge, while discharging decreases the SOC. For example, a battery that is half charged is at 50% SOC. Depth of Discharge (DOD) is the

3.17: Capacitor Charging and Discharging

Capacitor Charging and Discharging Experiment Parts and Materials To do this experiment, you will need the following: 6-volt battery Two large electrolytic capacitors, 1000 µF minimum

Summary of capacitor charging and discharging experiment

How do you charge and discharge a capacitor? This document describes an experiment on charging and discharging of capacitors. It involves using a 100μF capacitor, 1MΩ resistor, 9V

How to do charging and discharging experiment in battery cabinet

I am a University student, and while working on a vehicle ECU, we came across an issue where, when charging the vehicle battery from a high-current charger and running the car ancillaries,

Experimental data simulating lithium battery charging and discharging

Aug 1, 2024 · Through detailed testing of battery performance at different charge/discharge multipliers, this dataset provides an important reference for Battery Management System

Lithium battery cycle data analysis with curves and equations

The charge-discharge curve refers to the curve of the battery''s voltage, current, capacity, etc. changing over time during the charging and discharging process of the battery. The

Battery Charging Experiment Kit

Dec 3, 2018 · About KidWind The KidWind Project is a team of teachers, students, engineers, and practitioners exploring the science behind wind and other renewable forms of energy. Our goal

Charge Discharge Aging Cabinet For Battery Pack

AOT-BCDS100V aging cabinet is mainly used for charging and discharging cycle test of lithium battery, charging 20A and discharging 40A. Test items include:

Charging protocols for lithium-ion batteries and their impact

May 1, 2016 · The experimental results reveal that the impact of charging currents and charging voltages on cycle life can vary markedly among different lithium-ion batteries. In general, the

Battery Charge-Discharge Test | ESPEC CORP.

Charge/discharge cycle testing, which determines the number of times a battery can be used by evaluating it until it deteriorates after repeated cycles of

Capacitor Charging and Discharging Experiment

Nov 8, 2024 · Learn about the capacitor charging and discharging experiment for A Level Physics. This revision note covers the step-by-step method, analysis,

Semco-Hynn Charge and Discharge Cabinet

Jun 3, 2023 · A battery charge and discharge cabinet works by providing controlled conditions for charging and discharging batteries. It regulates the

10~100V Battery Pack Charging and Discharging

Aug 18, 2025 · Model NO.: Aging cabinet 100V Type: Finished Batteries Tester Test Region: Charge and Discharge Application: All Battery Pack Types

Capacitor charging and discharging experiment design

(5) describes of a discharging capacitor, it does not do so in terms of quantities which are easily measured. It can be manipulated to give predictions about measurable quantities by first

Capacitor charge and Discharge

1. Graphical representation of charging and discharging of capacitors: The circuits in Figure 1 show a battery, a switch and a fixed resistor (circuit A), and then

Battery pack charging and discharging experiment process

Do different initial charge levels affect a battery pack? This article studies the process of charging and discharging a battery pack composed of cells with different initial charge levels. An

Battery cabinet charging and discharging experiment diagram

How do you charge and discharge a capacitor? This document describes an experiment on charging and discharging of capacitors. It involves using a 100μF capacitor, 1MΩ resistor, 9V

How do charging and discharging patterns

Jan 8, 2025 · Charging and discharging patterns significantly impact the lifespan of batteries, particularly those using lithium-ion technology. Here''s how these

Battery Charging Cabinet Experiment Conclusion

In this study the analysis of charge and discharge characteristics of a commercial Li-ion battery is performed under C-rate 0.136 to 0.9 C in order to study the effects This paper proposes an

6 FAQs about [How to do charging and discharging experiment in battery cabinet]

How does a discharging circuit work?

The discharging circuit provides the same kind of changing capacitor voltage, except this time the voltage jumps to full battery voltage when the switch closes and slowly falls when the switch is opened. Experiment once again with different combinations of resistors and capacitors, making sure as always that the capacitor’s polarity is correct.

How do I set up a cyclic charge discharge experiment?

Go into the Framework software and navigate to “Experiment”- “Electrochemical Energy”- “Cyclic Charge Discharge”. Page one of the experimental setup screen will open. See figure 2. Name your experiment identifier under base file name. Capacity in A-hr. If known, it can be entered here. An approximate value is suitable.

What is a charge & discharge mode?

The options for either charge or discharge mode is constant current, constant load, constant power, and capacitance times N or divided by N (also known as “C” rate). Each of the modes will decide how to you will apply the a constant to the cell to see how it will handle the constant designed by your experiment.

How do I show a cyclic charge discharge in Echem analyst?

The Show Curve Selector button is selected in the top left of time. To do this, the first step will be to open the Echem Analyst software. From there you will want to click the Open icon. This will take you to C:\Users\Public\Documents\My Gamry Data. Then click on your cyclic charge discharge folder.

How do I access cyclic charge discharge files?

To do this, the first step will be to open the Echem Analyst software. From there you will want to click the Open icon. This will take you to C:\Users\Public\Documents\My Gamry Data. Then click on your cyclic charge discharge folder. Select the subfolder and select all the Charge and Discharge files. Press Open.

Do I need a large-value capacitor to do this experiment?

To do this experiment, you will need the following: Large-value capacitors are required for this experiment to produce time constants slow enough to track with a voltmeter and stopwatch. Be warned that most large capacitors are of the “electrolytic” type, and they are polarity sensitive!

Industry Information

- Juba 5G communication base station EMS power generation bidding

- Do energy storage batteries need pvdf

- Is the energy storage power supply for lighting good

- What are the batteries for wireless communication base stations in Madrid

- Hot sale wholesale substation breaker Factory

- Difference between 50hz and 60hz inverter

- Advantages of Huawei s photovoltaic power storage system

- Inverter exceeds rated voltage

- Inverter two-phase to three-phase electricity

- Super large capacitor

- Earth and Solar Power System

- New photovoltaic panel prices in San Diego

- Tirana outdoor power supply model specifications

- Italian photovoltaic off-grid energy storage

- Can I use an inverter when swapping lithium batteries

- China transfer switch breaker in Cape-Town

- Two 12V batteries connected in parallel to the inverter

- Haiti s new energy storage industry planning

- Install 5g communication green base station

- Photovoltaic glass 1297 specifications

- Congo photovoltaic energy storage products

- China wholesale 200w power inverter distributor

- Bucharest Liquid Air Energy Storage Project

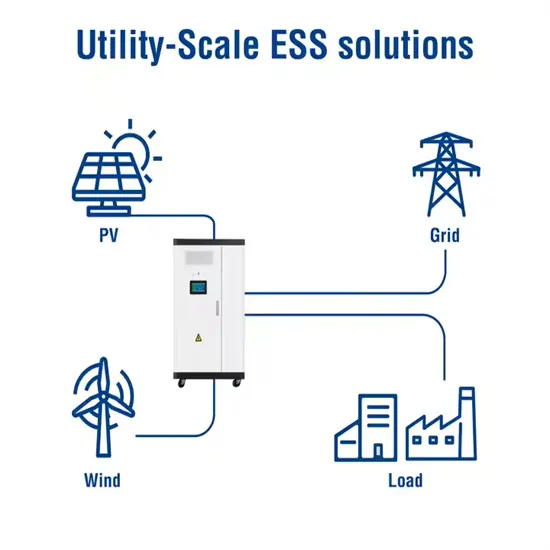

Commercial & Industrial Solar Storage Market Growth

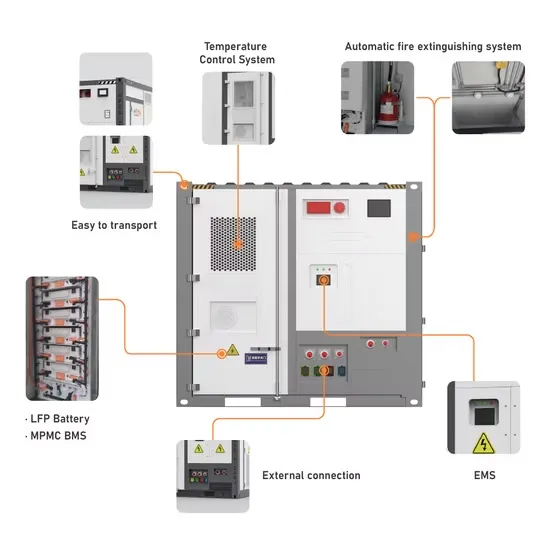

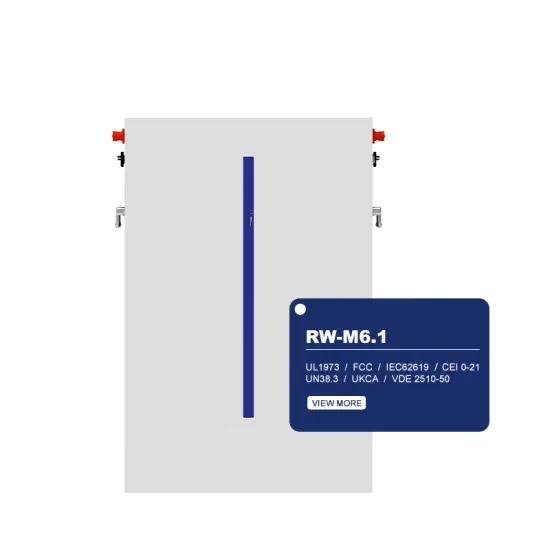

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

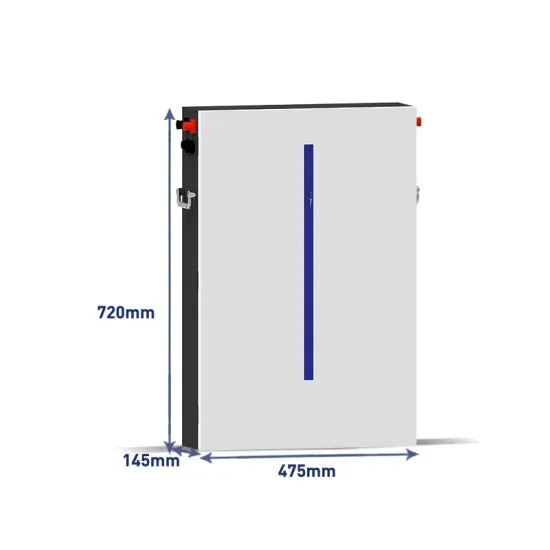

Solar Battery Innovations & Industrial Cost Benefits

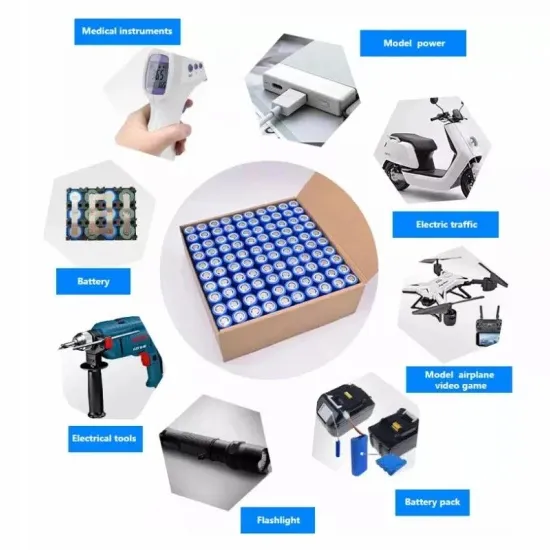

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.