PVDF Binder for Li-Ion Battery Electrodes:

Jan 21, 2025 · The global demand for efficient, high-performance lithium-ion (Li-ion) batteries continues to rise, driven by advancements in electric vehicles

Advances and prospects of PVDF based polymer electrolytes

Jan 1, 2022 · Clearing the progress of the present state and concluding the specific challenges faced by PVDF based electrolytes will help to develop PVDF based polymer batteries. In this

High-performance solid-state Li-ion batteries enabled by

Mar 1, 2024 · Rechargeable Li-ion batteries (LIBs) are widely employed across a variety of contexts, not only powering portable electronic devices but also serving as energy reservoirs

New EV Battery Solution Eliminates Toxic PFAS Chemicals

Dec 12, 2024 · The US startup Nanoramic underscores the bottom line benefits of sustainable EV battery manufacturing with a new PFAS-free electrode solution.

Significantly improved interface between PVDF-based

Apr 1, 2022 · They can quickly decompose at high potentials, limiting their applications in high-energy-density batteries [6]. The need for safe and high-energy-density storage has attracted

PVDF in Energy Storage: Boosting Battery Performance

May 30, 2025 · PVDF-based batteries are well-suited for grid-scale energy storage applications, helping to balance supply and demand in renewable energy systems and improve overall grid

Lithium-ion battery safety polymer electrolyte membrane

Apr 29, 2025 · Lithium ion batteries using liquid electrolytes often have safety issues, while all solid state electrolytes can ensure their safety, but their electrochemical performance still

A review on polymer electrolyte materials in context to

May 22, 2025 · This polymer is used in both solid (including the composite solid electrolyte) and gel polymer electrolytes. Keeping in view the energy demand and material scarcity in

PVDF: Why is it the material of choice for the lithium battery

Feb 12, 2025 · PVDF has certain flame retardant properties, which can slow down the burning speed of the battery to a certain extent and improve the safety of the battery. This is

A new type of LATP doped PVDF-HFP based electrolyte

Aug 5, 2023 · Lithium ion batteries are a widely used high-density energy storage device due to their low self-discharge rate and lack of memory effect. However, their use in liquid electrolyte

Understanding PVDF Binder for Lithium Ion Battery

2 days ago · As research continues, further innovations in PVDF modification are expected to contribute to the development of more efficient, durable, and high-performance batteries,

Fundamentals and perspectives of poly

In this review, we summarized the fundamentals of the PVDF-based solid-state electrolytes including the physicochemical properties, the ion transport

PVDF in Lithium-Ion Batteries: A Critical Material for Energy Storage

In the rapidly evolving world of energy storage, polyvinylidene fluoride (PVDF) has emerged as a critical material for lithium-ion battery technology. This fluoropolymer plays multiple essential

PVDF-HFP nanofiber quasi-solid electrolyte for fast charging

Jun 1, 2025 · To improve the fast charge/discharge performance of lithium-ion batteries, a nanofiber quasi-solid electrolytes (QSPE) with outstanding electrochemical properties, and

Polymers for Battery Applications—Active

In the light of an ever-increasing energy demand, the rising number of portable applications, the growing market of electric vehicles, and the necessity to store

Journal of Energy Storage

Dec 20, 2023 · Lithium ion batteries are a widely used high-density energy storage device due to their low self-discharge rate and lack of memory effect. However, th

High-Performance-Materials-for-Batteries_EN

Jul 18, 2018 · Solef® PVDF Binders and Materials for Separators Solvay is the only PVDF supplier that uses both emulsion and suspension polymerization technologies, thereby

Innovative Biobased Thermoplastic Binders for Sustainable

Jun 2, 2025 · The growing global demand for batteries has driven the search for sustainable materials for energy storage applications. One promising approach to enhance the

Why PVDF is the Secret Sauce in Modern Energy Storage Batteries

The answer lies in energy storage batteries using a special polymer called PVDF (Polyvinylidene Fluoride). This dynamic duo is quietly powering our transition to renewable energy while you

Elucidation of the Adhesion Mechanism for

Feb 21, 2025 · Based on our findings from NMR, SFG, infrared spectroscopy, and gel permeation chromatography measurements, we propose a mechanism for

Advancing lithium-ion battery technology with electrospun PVDF

May 1, 2024 · Electrospinning technology represents a rapid, cost-effective, and secure method for fabricating separators designed for lithium-ion batteries. Within this study, we employed

Achieving a high loading of cathode in PVDF

Sep 15, 2023 · However, PVDF-based SSLMBs are still difficult to pair with high-mass-loading cathodes to achieve high-energy-density SSLMBs towards

Alternative binders for sustainable

Abstract In this review, we discuss the most recent developments in the field of green binders for batteries and supercapacitors and explain how they could

PVDF for Lithium-ion Battery Market – PW Consulting Chemical & Energy

Feb 25, 2025 · The rapidly evolving energy storage and automotive industries are driving new demand dynamics for polyvinylidene fluoride (PVDF) in lithium-ion batteries, primarily due to

Does Energy Storage Require PVDF? The Critical Link in Modern Battery

Well, let''s cut to the chase: PVDF (polyvinylidene fluoride) has become the secret sauce in lithium-ion batteries powering today''s energy storage systems. As renewable energy capacity

Binding mechanisms of PVDF in lithium ion batteries

Jul 1, 2021 · The binding mechanism of polyvinylidene fluoride (PVDF) in lithium ion batteries (LIBs) is important for the development of new binders and the peelin

Dry Battery Electrode Technology: From Early

May 6, 2025 · The demand for efficient, sustainable, and cost-effective battery technologies is rapidly increasing, driven by the growing need for energy

How is PVDF used in lithium ion batteries?

Apr 16, 2024 · PVDF is known for its excellent compatibility with lithium-ion battery electrolytes. It exhibits good solubility in common organic solvents, allowing it to form a homogeneous

Composite Polymer Electrolytes: Transforming

Dec 16, 2024 · Developing high-performance solid polymer electrolytes (SPEs) represents a major leap forward for energy storage technologies, particularly

Lithium-ion battery safety polymer electrolyte membrane based on PVDF

Jul 1, 2025 · The results indicate that PVDF-HFP polymer electrolyte membranes containing SiO 2 have potential application prospects in high-temperature resistant lithium-ion batteries. 1.

Fundamentals and perspectives of poly

<p>Solid-state lithium metal batteries are considered as viable energy storage technologies for high-energy-density and safe devices. Recently, poly

Application of Polyvinylidene Fluoride Binders in Lithium-Ion Battery

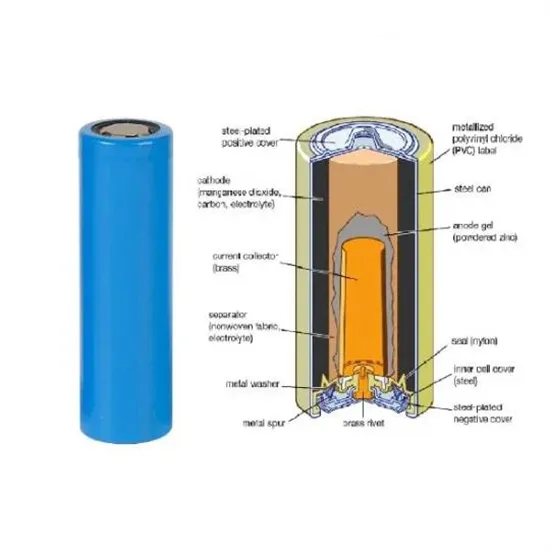

Jan 1, 2015 · Abstract Binder is a passive but an important part of lithium-ion battery (LIB), which provides interconnectivity within each electrode facilitating electronic and ionic conductivity.

PVDF-based solid polymer electrolytes for lithium-ion batteries

Apr 27, 2025 · Finally, the review concludes with future perspectives and challenges, outlining the potential of PVDF-based SPEs to address current limitations and pave the way for next

6 FAQs about [Do energy storage batteries need pvdf]

Why is PVDF a good battery?

PVDF has certain flame retardant properties, which can slow down the burning speed of the battery to a certain extent and improve the safety of the battery. This is particularly important for the application of lithium batteries in electric vehicles, energy storage systems and other fields. Wide operating temperature range

Can PVDF be used as a battery separator?

In addition to being a binder, PVDF can also be used to prepare battery separators. Its high porosity and stable electrochemical properties help to improve the permeability of the diaphragm and the wettability to the electrolyte, thereby enhancing the safety and performance of the battery.

Why is PVDF a good binder for lithium batteries?

Excellent bonding performance As a binder for lithium batteries, PVDF has excellent bonding effect. It can tightly bond the electrode active material, conductive agent and current collector together to ensure the stability and integrity of the battery structure during charging and discharging.

Are PVDF-based solid-state electrolytes suitable for lithium metal batteries?

Among SPEs, poly (vinylidene fluoride) (PVDF)-based solid electrolytes offer excellent thermal stability and mechanical strength, making them highly suitable for high-energy-density flexible batteries. This review presents recent advances in PVDF-based solid-state electrolytes (SSEs) for stable, high-performance lithium metal batteries (LMBs).

What is PVDF used for?

It is the second most produced fluoro resin after PTFE and is widely used in weather-resistant coatings, injection molding, lithium batteries, and photovoltaic backsheet films. As new energy industries like lithium batteries and photovoltaics grow rapidly, the demand for PVDF is increasing, especially for lithium battery applications.

Can modifying PVDF improve ion-conducting pathways in advanced lithium metal batteries?

These findings underscore the potential of modifying PVDF to create fast ion-conducting pathways, achieving significant improvements in ionic conductivity, lithium-ion transference, and overall stability in PVDF-based SSEs for advanced lithium metal batteries.

Industry Information

- Solar power satellite factory in El-Salvador

- Lobamba energy storage low temperature lithium battery

- Smart solar inverter in China in Sweden

- Huawei Portable Energy Storage Foundry

- Communication system base station

- Huawei Power System Energy Storage pAck Cooperation

- Xc90 high voltage inverter

- Maldives communication green base station room solution

- What is the spectrum range of flywheel energy storage in communication base stations

- Vanadium batteries for Cameroon energy storage power station

- Photovoltaic energy storage system villa

- Atess hybrid inverter factory in Uae

- Bangladesh communication base station flow battery module

- Roman Liquid Cooling Energy Storage

- How many square meters does solar energy have if it is 100 watts

- Double throw breaker in China in Niger

- Lome Photovoltaic Combiner Box Factory Direct Sales

- 4 2 kw solar inverter factory in Puerto-Rico

- Base station communication equipment power

- Huawei Mozambique Energy Storage Container

- How much does it cost to customize a containerized energy storage vehicle

- Voltage loss of photovoltaic panels

- Outdoor power cabinet design

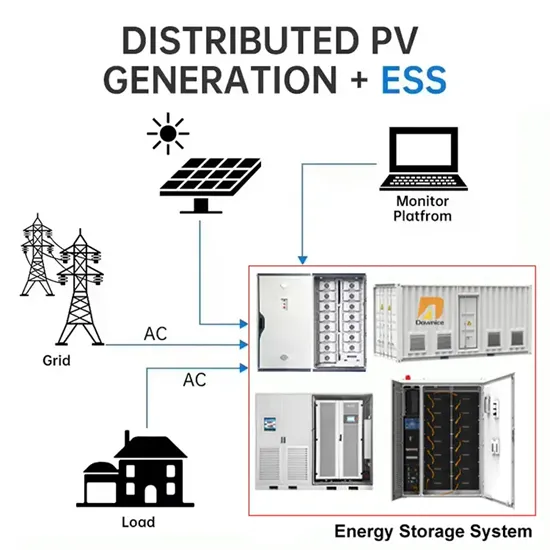

Commercial & Industrial Solar Storage Market Growth

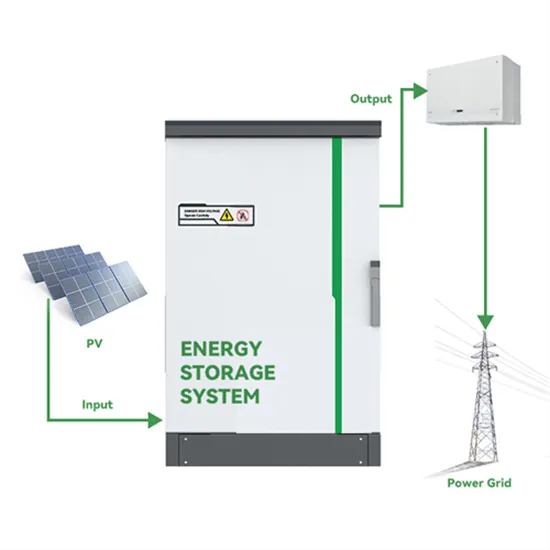

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.