Selecting Capacitors for Inverter Applications

This paper will present a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched DC to AC inverter using film capacitors and will

High Voltage Metallized DC Link Power Film

Jul 11, 2025 · DMJ-MC metalized film capacitor at CRE has competitive advantages over traditional electrolytic capacitor in frequency converters and

DC Bus Capacitor for Drive Inverters

3 days ago · The dc bus capacitor in high power traction motor drives need to deal with the following problems: (1) the ripple current due to inverter

Using YMIN Capacitors in DC/DC Converter

Feb 3, 2025 · A relatively high capacitance and a high DC voltage rating can buffer the downstream inverter from ripple and prevent the transmission of DC

High voltage DC-link capacitors

Jul 20, 2022 · DC link capacitors supply offset the impact of inductance in inverters, battery operation, and motor controllers. They provide filters that

Low Inductance Film Capacitors for Inverter Applications

Mar 15, 2024 · Low Inductance Film Capacitors for Inverter Applications CDE has Designed a DC-Link Capacitor that can Operate at Higher Switching Frequencies and Reduce Voltage Spikes

Selecting dc-link capacitors for inverters

Feb 9, 2021 · With the minimum capacitance and voltage rating chosen as discussed above, the next step is to calculate the total ripple current. A rule of

Selecting Dc-Link Capacitors In Power

May 10, 2017 · The output stage could be a switched mode converter or inverter taking bursts of high frequency current from the DC-link capacitor. The capacit

CAPACITORS

Oct 20, 2021 · Grid tie inverters require filter components in two key areas: The DC bus and AC output. The AC output filter is a low pass filter (LPF) that blocks high frequency PWM currents

Calculating DC-Link Capacitance for xEV

Aug 28, 2024 · There are many formulas to calculate DC-link capacitance in pulse-width modulated inverters of electric vehicles. This article illustrates a

How to Select DC Link Capacitor

The DC link capacitor is placed between the DC (in this case, the battery) and the AC (which is the load side) of the voltage inverter. The capacitor is placed

A switched-capacitor-based multilevel inverter with enhanced voltage

May 31, 2025 · With the growing demand for efficient and flexible power conversion, advanced topologies that provide high-quality multilevel AC output voltages with reduced complexity and

Modular Capacitors Smooth Out Power from High-Voltage

Oct 24, 2024 · The DC-link capacitor is placed in parallel between the inverter''s input stage that connects to the high-voltage EV battery and the power FETs on the output stage.

Capacitors in Power Electronics: A Simple

Apr 28, 2025 · DC link capacitor DC link means the connection between rectifier or ACDC converter and inverter, and is the system in which DC is supplied to

TPEL2691668

Sep 19, 2017 · In order to test the current sharing among the DC-link ca-pacitors, bus bar E is selected, which is designed for an inverter with five DC-link capacitors and three IGBT modules.

DC-Link Capacitors in Electric Vehicles

Jul 3, 2024 · In electric vehicle (EV) applications, DC link capacitors help offset the effects of inductance in inverters, motor controllers, and battery systems.

The Roles of Capacitors in EV Traction Inverter

Dec 13, 2023 · These capacitors act as filters, bypassing high-frequency noise. Decoupling Capacitors – In power supplies, decoupling capacitors are placed

DC Link Capacitors Selection and Arrangement Procedure in High

Dec 28, 2023 · The most important parasitic elements in high-power inverters are the ones associated with the DC-link and the capacitors used in its structure. This article wi

Capacitors for High Power

Mar 21, 2024 · DC Film The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use

High-Performance DC Link Capacitors

Our high-performance DC link capacitors enable fast switching in inverters, offering optimized bus topologies, high current ratings & low inductance.

Capacitors for DC Link | Products | TDK Product

4 days ago · TDK Corporation (TSE:6762) presents the B3271*H* series, new EPCOS film capacitors for DC link applications that feature high energy and

Selecting and Applying DC Link Bus Capacitors for

Oct 15, 2021 · Sam G. Parler, Jr., P.E. Cornell Dubilier Abstract, aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed drives

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · In this paper, we will discuss how to go about choosing a capacitor technology (film or electrolytic) and several of the capacitor parameters, such as nominal capacitance,

Capacitors | Products | TDK Product Center

4 days ago · TDK offers a large selection of highly reliable capacitors ranging from miniaturized MLCCs (multilayer ceramic chip capacitors) used in

DC Link Capacitors in Electric Vehicles

Given the high number of converters and inverters found in EV applications, selecting the right high-voltage, high-capacitance DC link capacitor is of great

DC-Link design tips: how to choose capacitors

Mar 24, 2021 · DC-Link capacitors are an important step in power conversion for a number of uses, including three-phase Pulse Width Modulation (PWM)

CAPACITORS

Apr 17, 2023 · Typically, aluminum electrolytic capacitors are the best option for power electronics applications requiring high capacitance (100''s of μF to Farads), up to 600 Vdc.

High-Energy Density Capacitors for Electric Vehicle Traction Inverters

Jun 26, 2020 · DC bus capacitors take up substantial space in a traction inverter, limiting the traction drive power density. Thus, several commercial capacitor technologies, under

9–Level switched capacitor–high-voltage gain boosting inverter

Jun 1, 2024 · This study introduces a new boost-type multilevel inverter named the "nine-level switched capacitor–high-voltage gain boosting inverter" (9LSC-HVGBI). Notably, this specific

Design Capacitors for Applications | DigiKey

May 13, 2016 · In a power inverter, a DC link capacitor is placed in parallel with the input to minimize the effects of voltage variations as the load changes. The

Selecting and Applying DC Link Bus Capacitors

Aug 14, 2025 · The capacitor voltage rating needs to exceed the worst-case peak bus voltage, such as under "high-line" mains conditions or maximum solar panel output voltage, etc. Low

DC-Link Capacitors Design Tips

Jul 28, 2022 · DC-Link capacitors form an essential stage in power conversion for many applications, including three-phase Pulse Width Modulation (PWM)

An eleven level single source switched capacitor boost inverter

2 days ago · The proposed structure, which consists of a single voltage source, 10 power electronic switches, 3 capacitors, and one diode, generates an 11-level stepped voltage

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

6 FAQs about [DC high voltage inverter capacitor]

Are electrolytic capacitors good for hard switched inverter bus link capacitors?

Electrolytic capacitors have been the workhorse technology for hard switched inverter bus link capacitors for many years. Electrolytic capacitor technology has also remained virtually unchanged over the years. Up till now, the greatest benefit in using electrolytic capacitors for bus link capacitors in inverters has been their cost.

Why does a DC link capacitor have a ripple current ICAP?

We may infer from Figure 2 that the DC link capacitor’s AC ripple current Icap arises from two main contributors: (1) the incoming current from the energy source and (2) the current drawn by the inverter. Capacitors cannot pass DC current; thus, DC current only flows from the source to the inverter, bypassing the capacitor.

How to sizing capacitors for inverter bus link applications?

The first step in sizing capacitors for inverter bus link applications should be to understand how much bus link capacitance is required for a given inverter design. The biggest design limitation for electrolytic capacitors in inverter applications has been the amount of ripple current that the electrolytic capacitor can sustain.

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

Are film capacitors a good choice for inverter power bridges?

Moreover, modern film capacitors not only perform better but can be a cost effective technology as well if applied correctly. inductance in an inverter power bridge leads to inefficiencies due to the voltage spikes they produce when the power devices are switched on and off at a high rate of dI/dt.

How much capacitor nameplate CV rating should a 3 phase inverter use?

For three-phase inverters at any DC bus voltage, for films and electrolytics, respectively, a rule of thumb is that about 5 and 50 millicoulombs of capacitor nameplate CV rating will be required per amp of ripple current.

Industry Information

- Camping 48v to 220v inverter

- Energy storage installation at charging station

- What are the energy storage systems in Porto Novo

- Yamoussoukro energy storage battery manufacturer

- 500w solar panel photovoltaic panel

- 12 Inverter V

- Rated power 700w inverter

- Cuba s new liquid flow battery brand

- Portable power bank market share

- Companies in San Diego that make energy storage systems

- Estonia Communications Green Base Station Mobile Project

- House circuit breaker factory in Canberra

- Desert high temperature solar air conditioning

- Can I bring an outdoor power supply to the customs in Pretoria

- Tirana 12v500ah energy storage battery

- Battery cabinet enterprise standard

- Wholesale 4000 amp switchgear in Lithuania

- Argentina Power Base Station Planning

- Factory price thermal breaker in Burundi

- Optical communication 5g base station

- Inverter constant power output

- 100 yuan sine wave inverter

- 500kw1mwh energy storage

Commercial & Industrial Solar Storage Market Growth

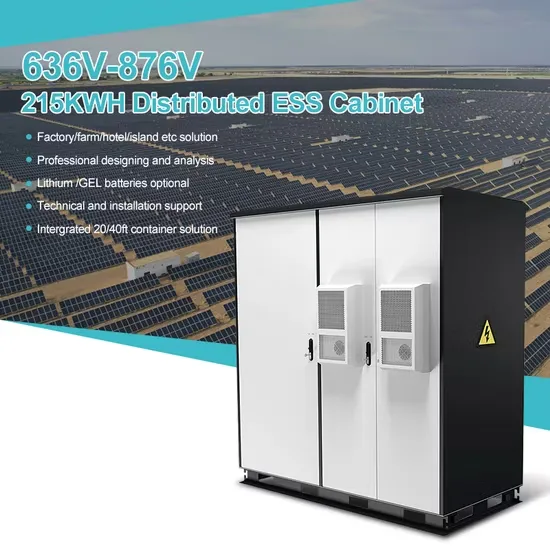

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.