How Solar Wafers Generate Electricity | NenPower

Aug 12, 2024 · Solar wafers are integral components of photovoltaic cells, facilitating the conversion of sunlight into electricity, which is pivotal for

Silicon Wafers: The Core of Solar Panels

Jan 18, 2024 · Silicon wafers, whether polycrystalline or monocrystalline, are essential materials in the manufacturing of solar cells. This article explores the types, preparation processes, surface

What materials are solar silicon wafers made of? | NenPower

Oct 20, 2024 · By combining these protective and functional characteristics, silicon dioxide enhances both the longevity and performance of solar photovoltaic systems. **Solar silicon

How do solar silicon wafers contribute to energy storage

Answer: Solar silicon wafers play a crucial role in energy storage systems by converting sunlight into electricity through the photovoltaic effect. These wafers, made from silicon crystals,

Wafer-Based Solar Cell

Wafer-based solar cells refer to solar cells manufactured using crystalline silicon (c-Si) or GaAs wafers, which dominate the commercial solar cell industry and account for a significant portion

Where are solar silicon wafers exported? | NenPower

May 24, 2024 · Components of solar panels directly influence their efficiency and cost. High-quality silicon wafers are essential for maximizing energy conversion rates. The photovoltaic

What is the silicon used in solar power

May 15, 2024 · Silicon used in solar power generation manifests in various forms, primarily classified into monocrystalline, polycrystalline, and amorphous

Principle of solar power generation from silicon wafers

Here, authors present a thin silicon structure with reinforced ring to prepare free-standing 4.7-mm 4-inch silicon wafers, achieving efficiency of 20.33% for 28-mm solar cells.

Advances in silicon nanowire applications in energy generation, storage

Feb 20, 2023 · Abstract Nanowire-based technological advancements thrive in various fields, including energy generation and storage, sensors, and electronics. Among the identified

Recycled silicon waste as a sustainable energy material

Jan 1, 2021 · Hence, researching uncommon physical behavior of silicon waste as an important breakthrough for next-generation sustainable devices will provide fundamental knowledge

Why SiC Wafers Are Important?

Sep 22, 2024 · What is a Silicon Carbide (SiC) Wafer? Silicon Carbide (SiC) wafers are semiconductors composed of a combination of silicon (Si) and carbon (C) atoms arranged in a

Si wafer technology for power devices: A review and future

Jun 25, 2018 · Silicon wafers have been widely used in semiconductor devices for years. Their characteristics have been improved by untiring development efforts to meet power

How Silicon Wafer Solar Cells Are

May 16, 2024 · The silicon wafer solar cell is essential in India''s solar revolution. It represents a leap in clean energy solutions. The tale of these cells includes

What is the power of solar silicon wafers?

Aug 31, 2024 · The power of solar silicon wafers is prominently linked to their role in facilitating efficient photovoltaic energy production. 1. Solar silicon wafers

Infineon Advances Power Semiconductors with

Oct 31, 2024 · Energy efficiency depends critically on the always-increasing reduction of wafers: half the thickness of a wafer lowers substrate resistance

Deeply Revealing The Secrets Of The Silicon

Jun 14, 2024 · According to SUMCO statistics, the sales amount of silicon wafers in mainland China in 2018 was approximately US$930 million, a year-on-year

The Smarter Solar Choice: How are Rectangular Silicon Wafers

Combined with rectangular wafers, bifacial N-type cells can achieve improved power generation from reflected light. They can achieve improved overall energy yield by up to 10–20%. 3.

The relationship between silicon wafers and solar power generation

The photovoltaic effect is used by the photovoltaic cells (PV) to convert energy received from the solar radiation directly in to electrical energy [3].The union of two

What are the uses of solar silicon wafers?

Apr 24, 2024 · 1. Solar silicon wafers are primarily employed in photovoltaic (PV) cells, playing a critical role in the conversion of sunlight into electricity, 2. They

What silicon materials are used in solar wafers? | NenPower

Jul 24, 2024 · Silicon materials used in solar wafers include various types of silicon, such as monocrystalline, polycrystalline, and amorphous silicon. Each type exhibits unique

New Study Explores Reusing Solar Panel Silicon for High

Apr 15, 2025 · The laser treatment process modified the surface of the silicon wafers, enhancing their mechanical stability and overall performance. Notably, the silicon wafers demonstrated

How are solar silicon wafers produced? | NenPower

May 14, 2024 · Impurities present in silicon can create energy states that disrupt the flow of electrical current or impede the generation of photon-generated

Solar Wafers: Key to Efficient Solar Panels

Nov 3, 2023 · Photovoltaic wafers or cells, also known as solar cell wafers, use the photovoltaic effect to convert sunlight to electricity. These cells come in

What Is A Silicon Wafer Used For?

Jun 7, 2024 · Monocrystalline silicon is currently the most common substrate for ICs, although gallium arsenide is used in some applications such as wireless

Silicon-based nanomaterials for energy storage

Jan 1, 2022 · To further boost the power and energy densities of LIBs, silicon nanomaterial-based anodes have been widely investigated owing to their low operation potential, high storage

High-efficiency Monocrystalline Silicon Wafers for

4 days ago · The Japanese government''s strong push toward clean energy adoption, as well as the development of next-generation solar technologies, have been crucial elements in shaping

Addressing Energy Consumption in Silicon

May 10, 2024 · The integration of renewable energy sources in silicon wafer production requires careful planning and consideration. One of the key

What is the work of solar power silicon wafers? | NenPower

Sep 9, 2024 · Silicon wafers contribute to improving energy efficiency, sustainability, and reducing dependence on fossil fuels.4. These wafers play a vital role in the growing solar industry,

Will silicon wafers be used for energy storage

Silicon wafers like this one are used by the Kiel research team to manufacture anodes for their innovative silicon batteries. An etching process gives the originally blank silicon wafers a

What Is a Silicon Wafer for Solar Cells?

Silicon wafers are a fundamental component in virtually all modern electronics and over 90% of solar cells & panels worldwide. But why? And how do they

The Role of Silicon Wafers in Advancing Green

Apr 16, 2025 · In EVs, silicon wafers are used in power electronics to manage energy distribution efficiently. Additionally, as the demand for energy storage

What are solar silicon wafers like? | NenPower

Jan 22, 2024 · The exploration of solar silicon wafers unveils their fundamental role within the solar energy landscape, highlighting both their efficiency and

How to make solar silicon wafers generate

Sep 30, 2024 · An intelligent energy management system will enable the operator to determine the optimal times for energy consumption, thereby enhancing the

6 FAQs about [Are silicon wafers used for power generation or energy storage ]

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

Are silicon wafers a good choice for high-efficiency solar cells?

In recent years, the diameter of silicon wafers manufacturers use for high-efficiency solar cells has increased — and so has the performance. Wafers as large as 210mm 2 (M12) are increasingly used in PV cells — a 35% increase in diameter from the original M0.

Why are wafer-based solar cells important?

There are multiple reasons why wafer-based solar cells are the essential component in over 90% of photovoltaic panels and other modules sold worldwide. Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells.

What are solar wafers used for?

The same thing is used as solar wafers for harnessing the sun’s energy. They have been designed for energy production and conservation and production. Think like this- a solar wafer supplier is a provider of clean energy solutions.

Are silicon wafer-based solar cells the future of photovoltaic technology?

Silicon wafer-based solar cells have long been the industry standard in photovoltaic applications worldwide. That’s unlikely to change anytime soon. Research and innovation are always ongoing but primarily focused on improving silicon wafer technology — not replacing it.

Industry Information

- Factory Photovoltaic Solar Panels

- String inverter is the most suitable for energy storage

- Ecuador smart ups uninterruptible power supply quotation

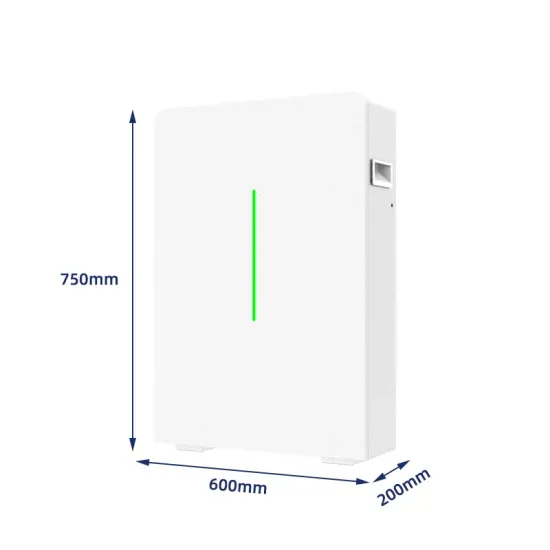

- Main engine factory battery cabinet storage standard

- ASEAN wind power storage and photovoltaic energy storage

- Wholesale suntree dc breaker in Yemen

- Castries Energy Storage Container Company

- What is the role of battery with inverter

- How much does a Windhoek inverter cost

- Base station power supply design standards

- Energy storage deployment in Finland

- Factory price 2 4 kw inverter in Suriname

- Greece-specific energy storage battery

- Solar power inverter in Rotterdam Netherlands

- Permanent magnet synchronous motor three-phase inverter

- 1c Energy Storage Power Station

- South America distribution room UPS uninterruptible power supply brand

- Outdoor power user journey

- Pretoria single glass photovoltaic module panels

- Sanaa Energy Storage Cabinet Battery Factory

- Tokyo Micro Inverter

- Argentina Energy Storage Container Manufacturing Plant Operation

- Onsite Energy Solar Powered Accessories

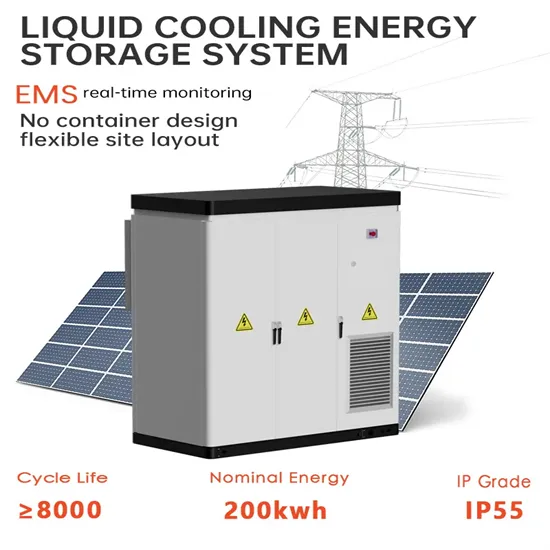

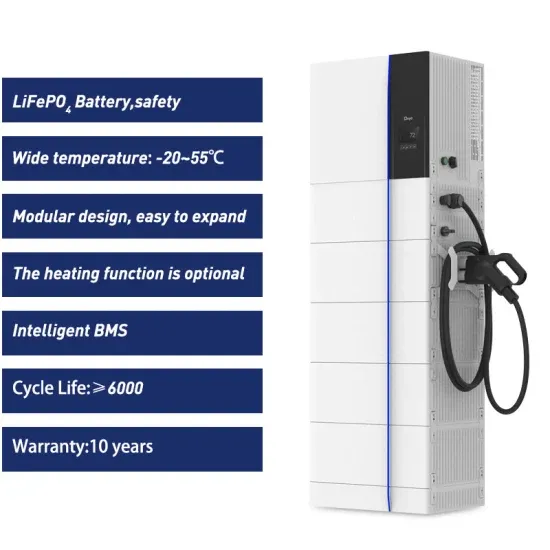

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.