Three-Phase PMSM Drive

Three-Phase PMSM Drive This example shows a Permanent Magnet Synchronous Machine (PMSM) in wye-wound and delta-wound configuration

Review of Permanent Magnet Synchronous Motor Fed

2 days ago · Abstract This paper presents a review of Permanent Magnet Synchronous Motor (PMSM) drive based on a three-phase Modular Multilevel Inverter (MMLI) compared to

Sensorless Field Oriented Control of 3-Phase Permanent

Apr 1, 2023 · This application report presents a solution to control a permanent magnet synchronous motor (PMSM) using the TMS320F2803x microcontrollers. TMS320F2803x

(PDF) An Open-Circuit Fault Diagnosis System

Feb 16, 2024 · An Open-Circuit Fault Diagnosis System Based on Neural Networks in the Inverter of Three-Phase Permanent Magnet Synchronous

System of six-leg, three-phase inverter for a

This paper focuses on the analysis and development of low-current harmonics for a six-leg, three-phase inverter for permanent-magnet synchronous motor

Torque Ripple Suppression Strategy for Three-Phase Permanent Magnet

Dec 5, 2024 · Torque Ripple Suppression Strategy for Three-Phase Permanent Magnet Synchronous Motor Based on Bidirectional Quasi Z-source Inverter. In: Yang, Q., Li, J. (eds)

Open-circuit Fault-tolerant Control for Three-phase Permanent Magnet

Dec 1, 2022 · In this paper, a single-phase open-circuit fault-tolerant control method for three-phase permanent magnet synchronous motor (PMSM) is proposed. Based on the 4-leg

Research on the Control Strategy of Three-Phase Four-Leg Inverter

Sep 25, 2022 · Aiming at the problem of load mutation affecting the stable operation of permanent magnet synchronous motor, a control method of permanent magnet synchronous motor based

3-phase PMSM Motor Control Power Inverter Module

Feb 1, 2024 · Application note AN13879 describes the design of a 3-phase Permanent Magnet synchronous Motor (PMSM) vector control drive with (Hall effect) LEM current sensors and

Permanent Magnet Synchronous Motors

This MATLAB® project provides a motor control example model that uses field-oriented control (FOC) to run a three-phase permanent magnet synchronous

Model predictive current control method of dual three-phase permanent

Oct 8, 2024 · In this paper, a model predictive current control (MPCC) method for dual three-phase permanent magnet synchronous motor (DTP-PMSM) based on improved SVPWM is

DESIGN OF MODULAR MULTILEVEL INVERTER FOR A

Oct 9, 2023 · Abstract: This project focuses on the design and implementation of a Modular Multilevel Inverter (MMI) tailored for a Permanent Magnet Synchronous Motor (PMSM) drive

Comprehensive dataset for fault detection and diagnosis in inverter

Feb 1, 2025 · This work introduces a new, comprehensive dataset for Fault Detection and Diagnosis (FDD) in inverter-driven Permanent Magnet Synchronous Motor (PMSM) systems.

Electric Drives

Control Velocity of Three-Phase PMSM with Open-End Winding Control the rotor angular velocity in an interior permanent magnet synchronous machine (IPMSM) with an open-end winding. A

Tptyc450 110kw 380V 191A 20Hz 60rpm Pmsm

Jul 30, 2025 · TPTYC series three-phase inverter permanent magnet synchronous direct drive motor The advantages of permanent magnet

Tptyc560 160kw 380V 274A 30Hz 90rpm Pmsm Motor Three-Phase Inverter

Aug 12, 2025 · TPTYC series three-phase inverter permanent magnet synchronous direct drive motor The advantages of permanent magnet synchronous motors compared with ordinary

Inverter Fault Diagnosis for a Three-Phase

Oct 8, 2023 · In this study, a novel intelligent inverter fault diagnosis approach based on a stacked denoising autoencoder–generative adversarial

Open Circuit Fault Diagnosis of Permanent Magnet Synchronous Motor

Jan 4, 2025 · A convolutional neural network combined with bidirectional long and short-term memory neural network (CNN-BiLSTM) fault diagnosis model is proposed for the open-circuit

807river/PMSM-Inverter-Design-PCB

Documenting the progress of an attempt to design an inverter for a permanent magnet synchronous motor (three-phase)记录尝试设计永磁同步电机(三相

Fault-Tolerant Control of Permanent Magnet Synchronous Motor

Feb 20, 2025 · In the vector control system of a Permanent Magnet Synchronous Motor (PMSM) using a T-type three-level inverter, switch faults such as open-circuit or short-circuit faults

Permanent Magnet Synchronous Motor (PMSM)

Aug 15, 2025 · Permanent magnet synchronous motors (PMSM) are typically used for high-performance and high-efficiency motor drives. High-performance

Research on the Control Strategy of Three-Phase Four-Leg Inverter

Sep 25, 2022 · Aiming at the problem of load mutation affecting the stable operation of permanent magnet synchronous motor, a control method of permanent magnet synchronous mo

Research on Modular Inverter Control Technology of Dual Three-Phase

Sep 23, 2024 · Using medium-voltage DC transmission instead of traditional three-phase AC transmission can significantly reduce cable losses. However, high DC bus voltages pose

Digital Twin Modeling Method of Three-Phase Inverter

Nov 6, 2023 · This article proposes a digital twin modeling method of a three-phase inverter-driven permanent magnet synchronous motor (PMSM) for system parameter estimation offline,

Advanced Simulation Model of Permanent Magnet

Aug 5, 2021 · Abstract— We are proposing an advanced simulation model of Permanent Magnet Synchronous Motor (PMSM). The developed simulation model is used to implement the vector

Permanent Magnet Synchronous Machine

This example shows the Permanent Magnet Synchronous Machine in a closed-loop speed and current control on a 1.1 kW, 3000 rpm industrial motor.

Designing a Three Phase Inverter for a Permanent

Jan 17, 2024 · In 2013 the team constructed its first fully electric car. In cooperation with ABB they built their own permanent magnet synchronous motor, which is controlled by a inverter from

Dual three‐phase permanent magnet

May 28, 2019 · A dual three-phase machine with interior permanent magnet rotor and distributed winding has been studied and compared to a commercial

Single-Phase Inverter Scheme for Permanent Magnet Synchronous Motor

Sep 27, 2018 · This paper proposes a method of driving a permanent magnet synchronous motor (PMSM) with a single-phase inverter and a capacitor. The proposed system combines variable

Inverter fault Analysis in Permanent Magnet

Mar 8, 2022 · AC machine drive systems.[1] there is a need to analyse the faults of permanent magnet synchronous motor. In this paper I am trying to analyse the performance of

Inverter Fault Diagnosis for a Three-Phase

Oct 8, 2023 · Inverter Fault Diagnosis for a Three-Phase Permanent-Magnet Synchronous Motor Drive System Based on SDAE-GAN-LSTM October 2023

Torque Ripple Suppression Strategy for Three-Phase Permanent Magnet

Dec 5, 2024 · In this paper, a power feed-forward correction strategy is proposed, which takes the disturbance of motor torque as a feed-forward quantity, combines with the small-signal

Mono inverter multi-parallel permanent magnet

Aug 4, 2025 · However, the majority of systems with Multi-PMSM requires one inverter per PMSM, a system with n three-phase-PMSM needs thus 3n inverter-legs. The main idea of this

Current harmonic elimination method for asymmetric dual three-phase

May 22, 2020 · Four-dimension current control for asymmetric dual three-phase permanent magnet synchronous motor based on vector space decomposition approach can eliminate the

6 FAQs about [Permanent magnet synchronous motor three-phase inverter]

What is four-dimension current control for asymmetric dual three-phase permanent magnet synchronous motor?

Four-dimension current control for asymmetric dual three-phase permanent magnet synchronous motor based on vector space decomposition approach can eliminate the harmonic currents induced by the nonlinear characteristics of inverter.

Is there a mechanical commutator in AC permanent magnet synchronous machines (PMSM)?

As there is no such mechanical commutator in AC Permanent Magnet synchronous Machines (PMSM), the functionality of the commutator has to be substituted electrically by enhanced current control.

What is Field Oriented Control for PM synchronous motors?

To achieve such control, field-oriented control is used for PM synchronous motors. The FOC concept is based on an efficient torque control requirement, which is essential for achieving a high control dynamic.

How many MOSFET inverter parts are there?

The assembled MOSFET inverter in figure31 can be seen in 8 modules. The purpose of separating it into 8 modules is to make failure search easier. The Inverter Module is one of these parts. Power Supply Module, Optocoupler Module, CAN Bus Module, and LCD are some of the other modules.

What is the dynamic model of IPMSM - flux linkage?

The dynamic model of an IPMSM (Interior Permanent Magnet Synchronous Motor) in terms of flux linkage can be described as a simplified equivalent circuit, as shown in Figure 8. The inductance can be divided into stator and rotor inductance, which is represented as L_{abcs} = L_{abcs} + L_{rlc()}, where L_{rlc()} = L_

How do rotor magnetic flux linkage pm and S1 produce BEMF voltage?

Based on Faraday’s law, rotor magnetic flux linkage ΨPM and stator magnetic flux linkage ΨS1 produce BEMF voltage EPM1=ωe1ΨPM perpendicularly oriented to rotor magnetic flux ΨPM in q-axis and BEMF voltage ES1=ωe1ΨS1 perpendicularly oriented to stator magnetic flux ΨS1, respectively (see Figure 14 left).

Industry Information

- The role of photovoltaic panels on the roof of a communication base station

- Myanmar Solar Cell Energy Storage Enterprise

- San Jose Photovoltaic Glass Types

- 60v6a energy storage battery

- Mobile intelligent energy storage power station

- China all in one solar system in Mozambique

- South Ossetia communication base station inverter photovoltaic

- 20W Solar Street Light

- Base station energy storage ebs

- 300W solar power to charge 105A battery

- Sucre Energy Storage System Lithium Battery

- Supercapacitor prices in the EU

- Zambia photovoltaic panel installation manufacturer

- Bissau quality inverter manufacturer

- And solar photovoltaic power generation system

- Sophia EK Nano-ion Energy Storage Battery

- Is it better for photovoltaic panels to have high or low voltage

- Three-phase micro photovoltaic inverter

- Canberra 12v400ah energy storage battery

- Bess battery storage for sale in Bandung

- 818KW digital display mixed frequency electromagnetic wave inverter

- Which is the best large solar power plant for communication base stations

- Cylindrical battery cell 14500

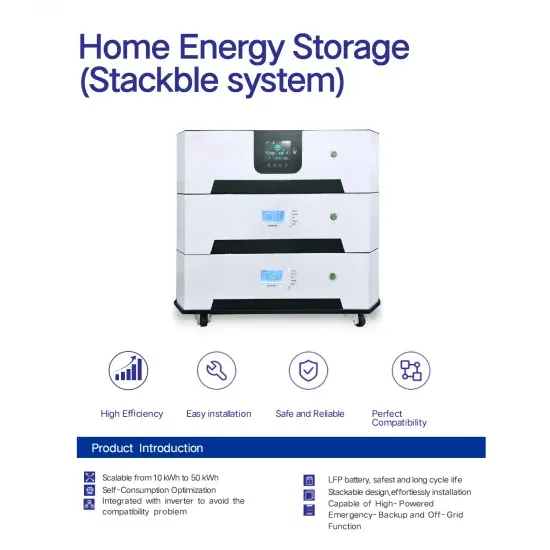

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.