Tesla adjusting battery pack production strategy

Jul 7, 2023 · Tesla''s push to start handing over a portion of its battery pack production to suppliers during the Model 3''s changeover window is a choice it

Effects of cell-to-cell variations on series-connected liquid

Dec 15, 2023 · It is commonly agreed that a battery pack''s end of life (EOL) comes when its maximum capacity deteriorates to 80 % of its nominal maximum capacity [11]. However, unlike

How to solve the problem if we encounter

3 days ago · Battery balancing is a crucial aspect of ensuring the optimal performance, longevity, and safety of your lithium battery systems. Whether

Lifetime and Aging Degradation Prognostics for Lithium-ion Battery

Jan 9, 2022 · The future degraded capacities of both battery pack and each battery cell are probabilistically predicted to provide a comprehensive lifetime prognostic. Besides, only a few

Battery Pack Thermal Design

Aug 17, 2016 · Battery Pack Thermal Design Ahmad Pesaran National Renewable Energy Laboratory Golden, Colorado NREL/PR-5400-66960 NREL is a national laboratory of the U.S.

Equivalent Series Resistance-Based Energy Loss Analysis

Oct 25, 2020 · Abstract—This paper provides a theoretical analysis on the en-ergy loss of a battery-ultracapacitor hybrid energy storage system based on the equivalent series

Nissan Leaf 63kW CATL Modules Battery –

PRODUCT: Brand-New Yaste NMC Battery Replacement for Nissan Leaf Battery Upgrade complete solution kit This product listing is for the sale of 1 unit of

Transfer time in UPS

Nov 23, 2017 · Transfer time is the amount of time a UPS will take to switch from utility to battery during a powercut. The lenght varies for different UPS

Navigating Through Power Outages with

Apr 29, 2024 · To mitigate these risks, Eco-ESS has developed innovative Automatic Changeover Switch (ACS) technology, specifically designed for

4-Switch Buck-Boost Bi-directional DC-DC Converter

Description The PMP21529 is 4-switch buck-boost bi-directional DC-DC power converter for use in battery backup power applications. During normal operation, the PMP21529 works as a

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

Current status and challenges for automotive

Apr 12, 2018 · Production technology for automotive lithium-ion battery (LIB) cells and packs has improved considerably in the past five years. However, the

Enabling New EV Battery Chemistries Through Battery Pack

Jan 7, 2025 · This article discusses the changes in battery pack design that impact which cell chemistries can be used in a commercially viable way. An overview is given for future adoption

Analysis of the cell-to-cell imbalance in battery pack based

Jun 17, 2021 · The conventional fault-diagnosis methods have limitations to clearly distinguish the battery faults in advance because these are focus on the cell-to-cell incon

Analysis of Cell-to-Cell Variation in a Battery Pack after Long

Oct 11, 2021 · The characterization and monitoring of lithium-ion battery systems during their service life in electric or hybrid-electric powered vehicles is relevant from a

Understanding Battery Inconsistency: Impact on Energy

Aug 1, 2025 · When batteries with inconsistencies are used together in series and parallel configurations, several issues can arise: 1. Loss of Usable Capacity. In an energy storage

How to Switch Two Batteries Manually using

Jan 23, 2024 · The following article explaining a dual battery changeover relay circuit was requested by Mr.Raja so that it could become possible to switch

Battery pack condition monitoring and characteristic state

Jan 1, 2025 · Battery packs consisting of a number of battery cells connected in series and/or parallel provide the necessary power and energy required in a wide ra

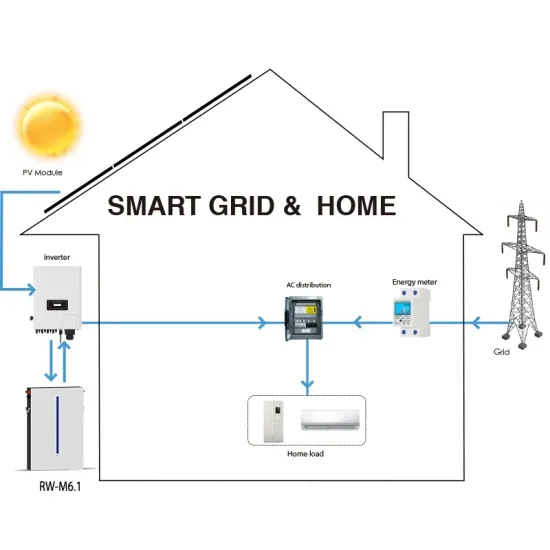

Understanding Solar Changeover Switches: A

2 days ago · A hybrid solar inverter is the combination of a solar inverter and a battery inverter into a single piece of equipment that can intelligently manage

''BT''s digital voice switchover has cut me off. Can

Aug 1, 2022 · After being promised a battery pack to solve the issue, I then had to chase BT again when it didn''t arrive, only to be told that no battery pack had

Do Battery Packs Lose Power? Tips for Lifespan, Charge

Apr 15, 2025 · Battery packs lose power over time because of limited charge-discharge cycles. Lithium-ion batteries usually maintain 80% capacity after around 500 cycles. Other types of

EV battery replacement costs and

Dec 9, 2023 · EV battery health depends on a variety of factors, including the individual owners'' charging habits (learn more

SPV Code of Practice

Mar 24, 2025 · Requirements of Battery Energy Storage Systems: Note the below requirements shall be met by the relevant components of the storage system such as the battery cells,

What Causes a Battery to Lose Capacity?

May 30, 2023 · Discover the intriguing world of batteries! Our deep-dive explores what causes a battery to lose capacity, unveiling the science behind this

How China is driving battery swapping as a

Oct 15, 2024 · Electric vehicles (EVs) have become a cornerstone of the global shift toward sustainability, and the demand for efficient and convenient

An Improved Bi‐Switch Flyback Converter with

Apr 27, 2024 · This paper focuses on the active cell balancing of lithium-ion battery packs. An improved single-input, multioutput, bi-switch flyback

The Science Behind Lithium Battery Capacity Loss

Aug 2, 2025 · What Causes Capacity Loss of lithium battery: SEI growth, lithium plating, and electrode degradation reduce capacity and shorten battery lifespan.

Battery configuration switch (BCS) for electric

Aug 1, 2025 · Eaton''s Battery configuration switch (BCS) solves this challenge in one innovative device that is integrated into the battery pack. Designed for

The Phases of a Changeover

May 30, 2017 · The image below is the combination of the two graphs above, showing both the phases causing loss of parts and the work steps for the

A study on parameter variation effects on battery packs for

Oct 1, 2017 · A set of parameters are introduced to study the cell variation and their impacts on battery packs are analyzed through the battery pack capacity loss simulation and experiments.

Battery Changeover Switches Explained

May 16, 2025 · What Is a Battery Changeover Switch? A battery changeover switch is a manually operated switch that allows users to select between two

Understanding aging mechanisms in lithium-ion battery packs

Mar 15, 2015 · Battery cell capacity loss is extensively studied so as to extend battery life in varied applications from portable consumer electronics to energy storage devices. Battery packs are

6 FAQs about [Battery pAck changeover loss]

What is the capacity loss of a battery pack?

The capacity loss of the battery pack is mainly composed of three parts. First, the capacity of the single cell cannot be fully utilized, resulting in inconsistencies capacity loss of the battery pack (marked as ΔCI ), which can be compensated through a conventional equalization method.

Why does a battery pack lose energy?

First, because of the inconsistent initial capacity and initial state of charge (SOC), the actual available energy of the battery pack is lower than any single cell; it will directly cause the loss of the energy density in group.

How EV battery pack capacity is determined?

Pack Capacity is Determined by Random Cell-to-Cell Variations and Deterministic Thermal Offsets One explanation for the larger cell-to-cell variation in used EV battery packs is the non-homogeneous load that each cell receives in real-life batteries. For instance, imperfect cooling systems result in a thermal gradient along the battery pack.

How many cells are in a battery pack?

The battery pack model with 96 cells in series is established. The influence factors of the consistency on battery pack are studied by simulation and experiment. The capacity loss composition of the battery pack is obtained and verified by the temperature variation experiment.

Does inconsistency affect battery capacity loss?

The inconsistency of the initial SOC and the initial capacity does not increase the battery capacity loss, and it was screened before in group, so it can be considered that the inconsistency has little effect on the inconsistency of the battery pack. Fig. 6 shows the capacity loss rate of the battery pack after 1000 cycles.

What happens if a battery pack is inconsistent?

Practice shows that the consistency of the battery pack will experience a gradual deterioration process. In general, the inconsistencies damage to the battery pack life is more serious than that of the durability of the single cell.

Industry Information

- How many independent energy storage power stations are there

- Manila outdoor power supply for sale

- Communication base station inverter users

- Uninterruptible power supply for a day

- Kyiv Communications Green Base Station Budget Company

- Advantages of polycrystalline silicon photovoltaic glass

- How much does a 10kw grid-connected inverter cost in North Korea

- The role of grid-side energy storage vehicles

- Best factory price 3000w inverters distributor

- Uninterruptible power supply 3ooW

- Belgium Mobile Outdoor Power Supply

- Solar power satellite factory in Philippines

- Managua corrosion-resistant photovoltaic curtain wall brand

- High quality 7 5 kva inverter in Kyrgyzstan

- Communication base station inverter grid-connected integrated cabinet load

- 2 5 kw solar inverter factory in Nigeria

- Capacity of wind power storage equipment

- What brand of outdoor power supply with large capacity is good

- Manila Portable Energy Storage Power Supply

- Lithium battery inverter wholesale

- Safe and economical outdoor power supply

- Is 6 kWh enough for an RV outdoor power supply

- How does a liquid-cooled energy storage cabinet store energy

Commercial & Industrial Solar Storage Market Growth

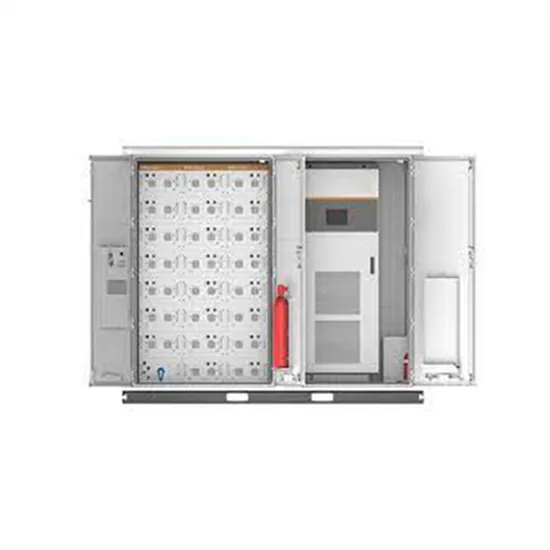

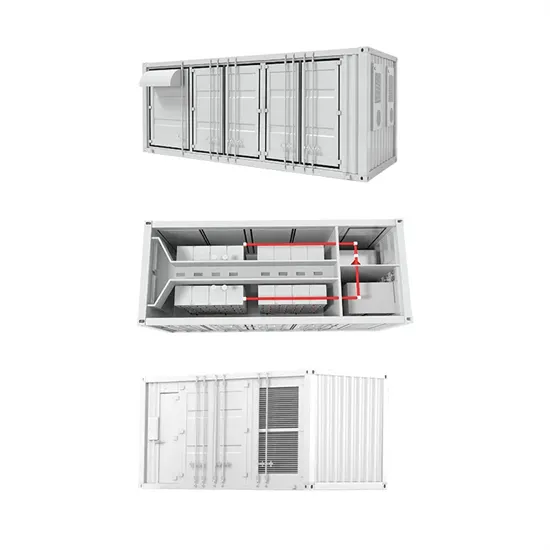

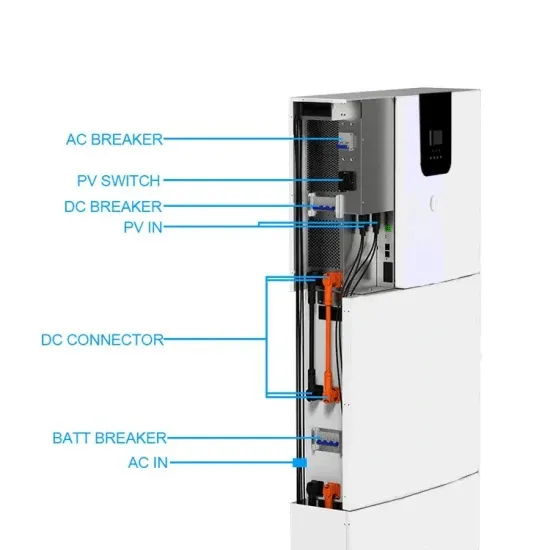

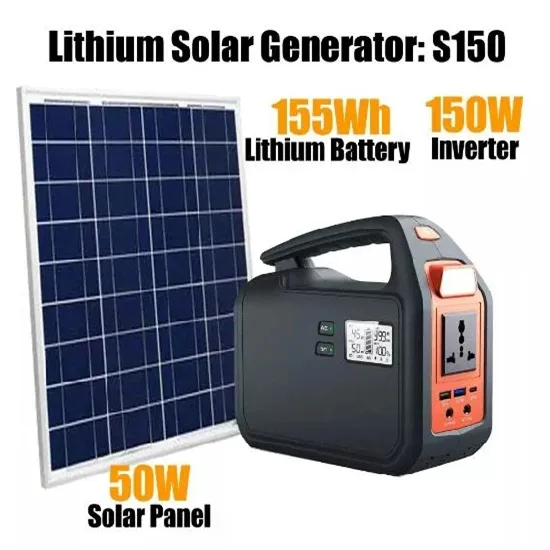

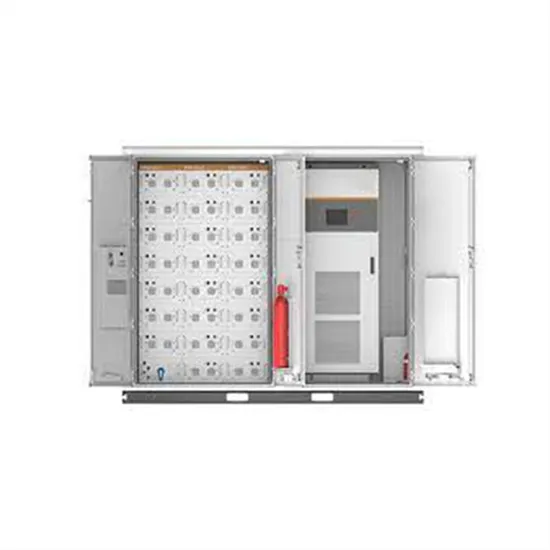

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.