Silicon-based solar cell: Materials, fabrication and applications

Jun 6, 2021 · In view of the destruction of the natural environment caused by fossil energy, solar energy, as an essential technology for clean energy, should receive more attention and

What Are the Benefits of Polycrystalline Silicon Solar Power

Sep 19, 2024 · Polycrystalline silicon solar cells, a type of photovoltaic technology, offer several benefits, contributing to their widespread use in solar power generation. Cost-effectiveness:

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Various technologies for mono- and polycrystalline PV cells are compared and discussed with respect to the corresponding material technologies, such as silicon ingot and

Polycrystalline Silicon

Jul 14, 2024 · Polycrystalline silicon, commonly known as polysilicon, is a high-purity form of silicon crucial to the photovoltaic (PV) industry. It is a fundamental material used to

CRYSTALLINE SILICON PHOTOVOLTAIC GLASS

2 days ago · One of the main advantages of crystalline silicon glass is its easy customization, allowing for unique shapes, including trapezoidal designs. With a higher nominal power

What are the advantages of double-glass photovoltaic

Oct 24, 2024 · 3. High conversion efficiency Double-glass photovoltaic modules use high-efficiency solar cells as photoelectric conversion devices, so they generate more electricity per

Silicon Solar Cell: Types, Uses, Advantages

Jul 14, 2022 · A silicon solar cell is a photovoltaic cell made of silicon semiconductor material. It is the most common type of solar cell available in

Monocrystalline Solar Panels: Advantages and

Good silicon feedstock is expensive (although less so in 2010 then it has been for a a while) and the cost of making a single pure crystal is time-comsuming and

Advantages and disadvantages of amorphous silicon

CIGS solar panels are much more expensive to produce than CdTe or amorphous silicon. The overall cost of a thin-film solar panel installation is usually lower than a monocrystalline or

The Advantages and Disadvantages of

5 days ago · In this article, we will explore the advantages and disadvantages of polycrystalline solar panels in more detail, including their cost-effectiveness,

An introduction to solar Polycrystalline Modules

Feb 21, 2012 · Polycrystalline silicon (polysilicon) is the material used to manufacture crystalline silicon PV modules and consists of small silicon

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · The basic principle behind crystalline silicon PV technology is the conversion of sunlight into electrical energy using semiconductor materials.

The Basics of Polycrystalline Solar Panels and

Aug 18, 2025 · Understanding the Different Types of Solar Panels There are several varieties of photovoltaic panels available on the market today, each

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · The glass is made with ultra clear rolled glass to take the most advantage of solar,the back side can be also glass panels or back opaque

Polycrystalline Solar Panel Materials, Types

Feb 13, 2025 · Moreover, the materials used in polycrystalline panels, such as silicon, glass, and aluminum, are abundant and recyclable. This reduces the

Technological status of polycrystalline silicon thin-film solar

Dec 1, 2013 · Thin polycrystalline silicon (poly-Si) films on glass seem to be an attractive candidate for this because they feature the potential to combine the advantages of both thin

Polycrystalline silicon thin-film solar cells: Status and perspectives

Dec 1, 2013 · Fabricated as thin layers, polycrystalline silicon also features all advantages of thin-film technologies, namely low costs due to low material wastage with up to factor 100 less

Advantages and Disadvantages of Polycrystalline

Aug 26, 2023 · Overview and Understanding of Polycrystalline Solar Panels Polycrystalline solar panels have several advantages, such as being cheaper

What are polycrystalline silicon solar cells?

Sep 22, 2024 · The exploration of polycrystalline silicon solar cells reveals a complex interplay of advantages and disadvantages that define this

A comparative study of mechanical crushing and

Sep 15, 2024 · Abstract With the rapid growth of the photovoltaic (PV) industry, efficient recovery and utilization of discarded polycrystalline silicon PV modules have attracted increasing

Polycrystalline silicon thin-film solar cells: Status and

Dec 1, 2013 · Fabricated as thin layers, polycrystalline silicon also features all advantages of thin-film technologies, namely low costs due to low material wastage with up to factor 100 less

Quartz Glass Advantages: Key Benefits for Solar Photovoltaic

Discover the quartz glass advantages and benefits for solar photovoltaic manufacturing, including high purity, thermal stability, and superior light transmission.

Disadvantages of polycrystalline silicon photovoltaic panels

What are the disadvantages of polycrystalline solar panels? However,the disadvantages of polycrystalline solar panels include the lower efficiency ratedue to the less pure silicon

Monocrystalline silicon: efficiency and

Sep 3, 2018 · In this way, impurities that would affect the uniformity of the glass are avoided. Compared to polycrystalline ingot molding, monocrystalline

What are the benefits of polysilicon

Dec 2, 2024 · Polycrystalline silicon offers advantages such as high purity, strong durability, and low production costs, making it widely used in solar cells and electronic devices.

Advantages & Disadvantages of Monocrystalline

Apr 30, 2020 · In this article, you will learn everything you need to know about the advantages and disadvantages of monocrystalline silicon solar panels.

Polycrystalline silicon on glass thin-film solar cells: A

Dec 1, 2013 · Solar cells fabricated from LPCSG films using the CSG technology have achieved 585 mV open circuit voltage and 11.7% efficiency. The paper presents a review of major

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · What are polycrystalline solar panels? Polycrystalline solar panels are the result of melted polysilicon being poured into moulds, which are cut

What Is A Polycrystalline Solar Panel? | Definition, Cost, Advantages

Feb 11, 2025 · A polycrystalline solar panel, also known as a multi-crystalline solar panel, is a type of photovoltaic (PV) panel used to convert sunlight into electricity. These panels are

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · Polycrystalline solar panels are one of the most efficient, powerful, long-lasting types of solar panels in history – but they''ve been rapidly outpaced on all fronts by

Solar panel types and differences:

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

6 Advantages Of Polysilicon Solar Cells

May 17, 2024 · Polysilicon solar cells offer enhanced durability, cost-effectiveness, and reliable performance in various climates. They maintain efficiency over 25 years, with average

Crystalline and thin-film silicon solar cells: state of the art

Mar 1, 2003 · One new approach is based on a stack of two silicon thin-film cells, one cell using amorphous silicon and the other mixed-phase microcrystalline silicon. The second uses silicon

Polycrystalline silicon solar cells

Jan 1, 2021 · The silicon demand for photovoltaic applications will be increased. The relations among the manufacturers of polycrystalline silicon with demand in the market from 2003 to

PHOTOVOLTAIC GLAZING IN BUILDINGS

Jul 15, 2022 · PV glazing is an innovative technology which apart from electricity production can reduce energy consumption in terms of cooling, heating and artificial lighting. It uses

6 FAQs about [Advantages of polycrystalline silicon photovoltaic glass]

What are the advantages of polycrystalline solar panels?

One of the substantial advantages of polycrystalline solar panels is their lower cost. The manufacturing process is simpler and less wasteful than their monocrystalline counterparts—no silicon is wasted in their production as multiple silicon crystals are melted together.

Are polycrystalline solar panels worth it?

Polycrystalline solar panels are one of the most efficient, powerful, long-lasting types of solar panels in history – but they’ve been rapidly outpaced on all fronts by monocrystalline modules. This is why they’ve sunk into irrelevance when it comes to new installations.

What are polycrystalline solar panels?

Polycrystalline solar panels are the result of melted polysilicon being poured into moulds, which are cut into wafers and fashioned into solar cells. This type of silicon panel dominated the UK market for decades, starting with the country’s very first domestic solar panel system in 1994.

What are the disadvantages of polycrystalline solar panels?

They also have a slightly higher heat tolerance than other types. However, the disadvantages of polycrystalline solar panels include the lower efficiency rate due to the less pure silicon used, and their appearance, which some consider less appealing due to the blue, speckled look of the panels. Monocrystalline Vs.

How do polycrystalline solar panels work?

Like other solar panels, polycrystalline solar panels operate by converting sunlight into usable electricity. They leverage the photovoltaic effect, where solar radiation prompts electrons in a solar cell to move, thereby creating electricity. It’s a clean, renewable energy source that comes right from the sun – no middlemen, no emissions.

Should you choose a polycrystalline or monocrystalline solar panel?

Therefore, if space is a consideration, more efficient panel types might be a better choice. While the lifespan of a solar panel is significantly dependent on its maintenance and exposure to environmental stressors, in general, polycrystalline solar panels may not last as long as monocrystalline ones.

Industry Information

- North Korea s energy storage container industry and commerce

- Simple solar panel power generation system

- Mobile base station solar panels

- Photovoltaic module 545 monocrystalline double-sided

- Gaborone Photovoltaic Panel System Manufacturer

- How many types of photovoltaic energy storage systems are there

- Niue battery cabinet manufacturer

- Is there any site energy battery cabinet in Berlin

- Battery inverter model

- What is the minimum volt of outdoor power supply

- Riyadh Energy Storage Photovoltaic Engineering Enterprise

- Bess battery storage in China in Brisbane

- Communication Green Base Station on the roof

- The role of sodium-ion battery energy storage cabinet

- Photovoltaic inverter wfi

- Which kind of outdoor power supply is better in Riga

- Energy storage emergency power cabinet industrial design

- Construction site 220 inverter

- Hot sale power breaker switch factory producer

- How many magnetic 5g communication base stations are there

- Huawei Indonesia Surabaya Capacitor Energy Storage Project

- North Korea supercapacitor module price

- Integrated communication base station battery energy storage system battery

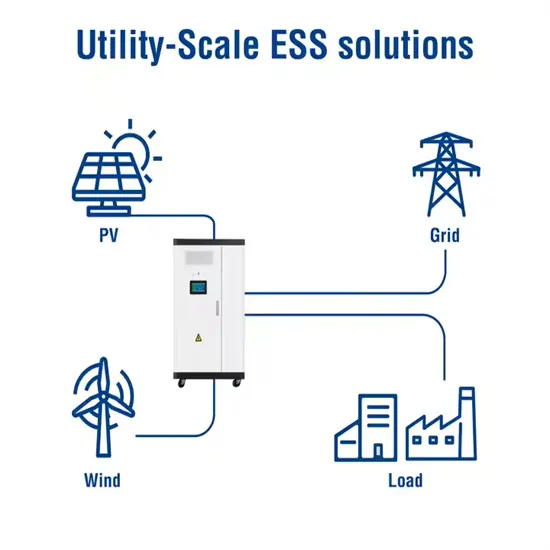

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

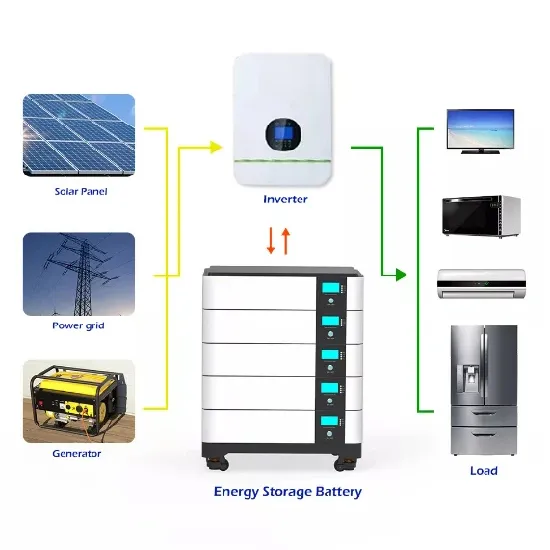

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.