Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Telecom Base Station Backup Power Solution:

Jun 5, 2025 · Designing a 48V 100Ah LiFePO4 battery pack for telecom base stations requires careful consideration of electrical performance, thermal

INSTRUCTIONS FOR INSTALLATION, OPERATION AND

May 28, 2020 · A lead acid battery is a number of cells filled with a mixture of sulfuric acid and water called electrolyte. The electrolyte covers vertical plates made of two types of lead.

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and Communications Technology)

Designing Industrial Battery Rooms: Fundamentals and

IEEE 484: Recommended Practice for Installation Design and Installation of Vented Lead-Acid Batteries Technology-Specific Considerations Different battery technologies have unique

1926.441

Aug 15, 2025 · Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

OSHA 1926.441: What to Know About OSHA''s

Jan 22, 2020 · Learn everything you need to know about OSHA 1926.441, standards for battery handling in the construction industry, without having to

INSTALLATION OPERATING INSTRUCTIONS

Oct 22, 2020 · CAUTION! Before proceeding with the unpacking, handling, installation and operation of a lead-acid storage battery, the following general information should be reviewed

Installation location of lead-acid batteries for communication base

Lithium-ion batteries can be a suitable replacement for lead acid batteries, offering advantages such as faster charging times and higher energy density. we will explore various aspects

GUIDELINES FOR SUCCESSFUL INSTALLATION OF LARGE

Jan 10, 2023 · This paper makes recommendations and provides guidelines relating primarily to the handling, installation and bench marking processes for large lead-acid battery systems of

Application-related requirements for the operation of

Jul 24, 2024 · Electrolyte-impermeable floor or installation of electrolyte collection trays underneath closed lead-acid batteries. When installed in enclosures, this must have adequate

Section 7 Batteries

Feb 5, 2024 · The electrolyte cannot normally be replaced. 7.1.4 The following Sections apply to lead acid, nickel cadmium and lithium cell chemistries. While some of the same mitigations

Common problems and solutions for the installation and

Jul 22, 2025 · Remember, every recycling facility for lead-acid batteries – even those with identical equipment models – has unique challenges. Stay observant, log everything, and build

Maintenance and care of lead-acid battery packs for solar communication

The battery pack is an important component of the base station to achieve uninterrupted DC power supply. Its investment is basically the same as that of the rack power supply equipment.

IEEE SA

Feb 21, 2001 · This standard provides general requirements, direction, and methods for qualifying Class1E electric cables, field splices, factory splices, and factory rework for service in nuclear

Installation, commissioning and operating instructions

IEEE Standard 1187–2002: „Recommended Practice for Installation Design and Installation of Valve Regulated Lead-Acid Storage Batteries for Stationary Applications".

Installation diagram of lead-acid battery for communication base

In this tutorial we will understand the Lead acid battery working, construction and applications, along with charging/discharging ratings, requirements and safety of Lead Acid Batteries.

Selection and maintenance of batteries for communication base stations

Focused on the engineering applications of batteries in the communication stations, this paper introduces the selections, installations and maintenances of batteries for communication

Overview of Telecom Base Station Batteries

1)Determine the battery''s installation location according to the layout of the base station equipment and battery size. 2)Connect the battery circuit according to

484-2019

Jul 17, 2020 · Scope: This recommended practice provides recommended design practices and procedures for storage, location, mounting, ventilation, instrumentation, preassembly,

VRLA Installation and Commissioning

Nov 6, 2018 · IEEE Standard 1187 establishes the recommended practices for the design and installation of valve-regulated lead-acid (VRLA) batteries.

EngineeredSystems May 2018: Designing Ventilation For Battery

May 3, 2018 · The International Fire Code (IFC) requirements are such that when the battery storage system contains more than 50 gallons of electrolyte for flooded lead-acid, nickel

29 CFR 1910.178 (g) (2); Battery Charging Stations for Fork

5 days ago · OSHA Instruction October 30, 1978 STD 1-11.4 OSHA PROGRAM DIRECTIVE #100-72 TO: REGIONAL ADMINISTRATORS/OSHA THRU: DONALD E. MACKENZIE Field

Battery Energy Storage System Installation requirements

Mar 16, 2021 · This standard places restrictions on where a battery energy storage system (BESS) can be located and places restrictions on other equipment located in close proximity to

Regulatory Guide 1.128, Revision 2, Installation Design

Jun 11, 2023 · A. INTRODUCTION The U.S. Nuclear Regulatory Commission (NRC) developed this regulatory guide to describe a method that the NRC staff considers acceptable for use in

What is the purpose of batteries at telecom base

Feb 10, 2025 · Telecom batteries refer to batteries that are used as a backup power source for wireless communications base stations.

Designing Ventilation For Battery Rooms | 2018

May 7, 2018 · Typical battery SSBS are composed of batteries of the flooded lead-acid batteries, Valve Regulated Lead-Acid (VRLA), or nickel-Cadmium

Lead-acid batteries

Oct 18, 2024 · Ventilation (natural or forced), maintenance schedules, battery performance testing, the proximity and location of other electrical equipment or sources of ignition and

Mobile communication base station

Outdoor cabinet solution with base station equipment, power supply equipment, lead-acid batteries, temperature control system, transmission and other ancillary equipment. The

Understanding Backup Battery Requirements for

Mar 7, 2025 · Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is

1635-2018

Jul 31, 2018 · Vented lead-acid (VLA), valve-regulated lead-acid (VRLA), and nickel-cadmium (NiCd) stationary battery installations are discussed in this guide, written to serve as a bridge

Storage battery requirements

Jan 27, 2017 · While certain designs, such as valve-regulated lead-acid (VRLA) batteries, dramatically reduce the amount of hydrogen released into the

Telecom battery backup systems

Mar 3, 2023 · Telecom battery backup systems mainly refer to communication energy storage products used for backup power supply of communication

6 FAQs about [Installation requirements for lead-acid battery equipment for small communication base stations]

What are recommended design practices and procedures for vented lead-acid batteries?

Abstract: Recommended design practices and procedures for storage, location, mounting, ventilation, instrumentation, preassembly, assembly, and charging of vented lead-acid batteries are provided. Required safety practices are also included. These recommended practices are applicable to all stationary applications.

What makes a telecom battery pack compatible with a base station?

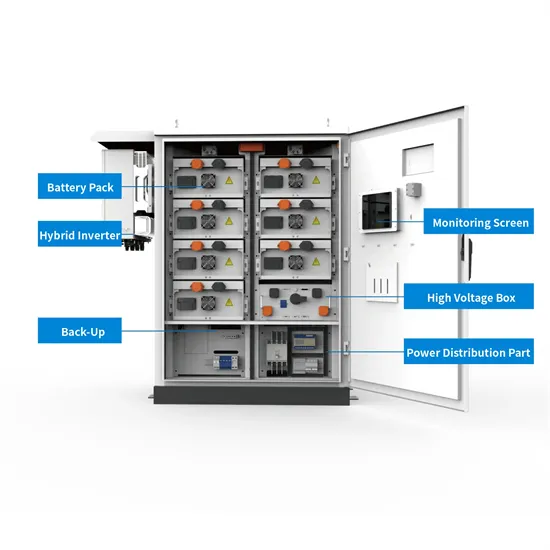

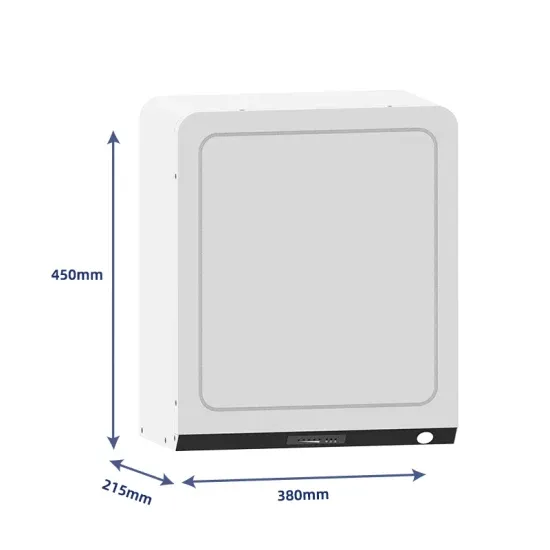

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

Which battery is best for telecom base station backup power?

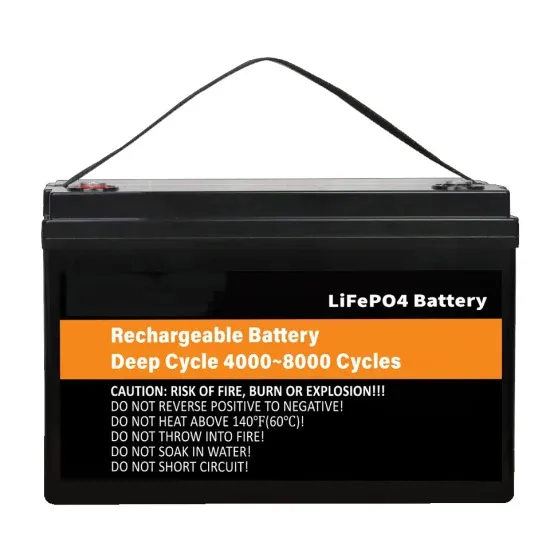

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

How do you protect a telecom base station?

Backup power systems in telecom base stations often operate for extended periods, making thermal management critical. Key suggestions include: Cooling System: Install fans or heat sinks inside the battery pack to ensure efficient heat dissipation.

What should be included in a battery maintenance plan?

Sizing, maintenance, capacity testing, charging equipment, dry-charged units, and consideration of other types of batteries are beyond the scope of this recommended practice.

What makes a good battery management system?

A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging. Temperature Management: Built-in temperature sensors to monitor the battery pack’s temperature, preventing overheating or operation in extreme cold.

Industry Information

- Sunshine Energy Storage Company and Photovoltaic Power Source

- High Power Outdoor Power Supply Company

- 13000w12v24 universal inverter high power

- What does 60kwh of battery energy storage mean

- Wholesale 1500 power inverter in Estonia

- Four-line solar photovoltaic container China

- Management and application of power battery pack

- Construction and installation of uninterrupted power supply for communication base stations

- BAK battery 21700

- Sf6 circuit breaker in China in Nigeria

- Manama container generator manufacturer

- Optical Cable Communication Base Station Energy Management System

- Normal photovoltaic inverter

- Price of explosion-proof photovoltaic panels in Belize

- Czech solar lighting logo

- Bangi Household Solar Photovoltaic System

- Industrial energy storage system installed

- Amsterdam pack lithium battery

- Size of photovoltaic panels on rural house roofs

- Solar controlled water pump

- Automatic balancing of lithium battery pack

- Majuro communication base station installation energy storage cabinet requirements

- Guatemala electric warehouse truck lithium battery pack

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.