Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to

A safety performance estimation model of lithium-ion batteries

Jan 15, 2021 · The simulation and experimental results show that the safety warning of the cylindrical lithium-ion battery based on mechanical penetration has a certain safety margin,

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and

Reliability of Cylindrical Li-ion Battery Safety Vents

May 26, 2020 · Cylindrical Li-ion batteries (cells) typically have safety vents in the positive terminal to enable the release of gases that build up inside the battery and thus help reduce

What Does a Lithium-Ion Battery Look Like?

May 12, 2025 · Lithium-ion batteries are integral to our daily lives, powering everything from smartphones to electric vehicles. Understanding what a lithium-ion battery looks like helps in

Cylindrical Lithium Technologies

5 days ago · Cylindrical Lithium battery technology by Panasonic Energy Co., Ltd. High Energy Formula and PTC Safety System.

Circulating oil-immersed battery thermal management

Jun 1, 2024 · Since the lifetime of lithium-ion battery (LIB) is directly related to the operating temperature, it is important to investigate efficient and safe thermal management strategies.

Study on the safety of cylindrical lithium-ion batteries under

This study aims to elucidate the safety performance of lithium-ion batteries under nail penetration conditions. Utilizing a custom-built experimental platform, we examined the effects of four

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

A Review of Lithium-Ion Battery Failure Hazards:

Nov 20, 2022 · The frequent safety accidents involving lithium-ion batteries (LIBs) have aroused widespread concern around the world. The safety standards of

Design, Properties, and Manufacturing of

Jun 3, 2023 · This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical

Cylindrical Cell-EVE

Cylindrical Cell*Above data comes from EVE''s laboratory. Product performance may differ in different products, please contact us for details.

Tab Design and Failures in Cylindrical Li-ion Batteries

Feb 15, 2019 · The tabs that connect the electrodes (current collectors) to the external circuits are one aspect of the cylindrical battery design that plays a role in reliability and safety. This paper

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Safety devices are very important for using any types of lithium-ion batteries because lithium is highly energetic materials and electrolyte is flammable. Therefore,

Safety Analysis of Lithium-Ion Cylindrical

Feb 23, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

Safety modelling and testing of lithium-ion batteries in

Apr 12, 2018 · Battery safety is a key focus in the design of electrified vehicles. Here, the authors survey literature approaches for modelling and testing battery safety under abuse conditions,

Safer operating areas (SOA) of cylindrical lithium-ion battery

Oct 1, 2024 · Abstract This study introduces a real-time probabilistic safety assessment of a 18650 cylindrical battery. The physics-based failure scenarios from battery abuse are mapped onto

ARTICLE INFORMATION SHEET/SAFETY DATA SHEET

Jan 19, 2023 · Cylindrical Lithium Manganese Dioxide Battery This Article Information Sheet (AIS) provides relevant battery information to retailers, consumers, OEMs and other users

Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · Understanding lithium-ion battery failure under mechanical abuse is critical for safety. While continuous compression is studied, the effects of inter

Failure Analyses of Cylindrical Lithium-Ion Batteries Under

Mar 17, 2025 · To describe the mechanical response of cylindrical batteries more comprehensively, Zhu et al. [16] established a detailed model of cylindrical lithium-ion

Safer operating areas (SOA) of cylindrical lithium-ion battery

Oct 1, 2024 · This study introduces a real-time probabilistic safety assessment of a 18650 cylindrical battery. The physics-based failure scenarios from battery abu

Types of LiFePO4 Battery Cells: Cylindrical,

May 15, 2025 · Long Cycle Life: Similar to cylindrical cells, prismatic cells can handle extensive cycling, which enhances their value in long-term

Unlocking the significant role of shell material for lithium-ion

Dec 15, 2018 · The cylindrical lithium-ion battery has been widely used in 3C, xEVs, and energy storage applications and its safety sits as one of the primary barrie

Cylindrical lithium battery classification and

May 17, 2023 · The structure of a typical cylindrical battery includes:casing,cap,positive electrode,negative

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

PRODUCT SAFETY DATA SHEET

Oct 2, 2019 · PRODUCT SAFETY DATA SHEET PRODUCT NAME: Energizer Battery TRADE NAMES: Cylindrical Lithium Manganese Dioxide Batteries CHEMICAL SYSTEM: Lithium

Cylindrical Lithium Battery Cap: Manufacturing

May 21, 2024 · Cylindrical lithium batteries are popular for their efficiency, lifespan, and compact size. But their safety hinges on a crucial component:

LITHIUM BATTERY SAFETY

Jul 10, 2025 · Studies have shown that physical damage, electrical abuse such as short circuits and overcharging, and exposures to elevated temperature can cause a thermal runaway. This

A typical safety vent in a cylindrical Li-ion

Cylindrical Li-ion batteries (cells) typically have safety vents in the positive terminal to enable the release of gases that build up inside the battery and

Cylindrical cells Archives — Large Battery

As a leading cylindrical cell manufacturer, Large Power supplies a wide range of cylindrical lithium-ion and LiFePO4 cells suitable for both small-scale and industrial battery pack

Cylindrical Cells

Aluminium Cell Housings for Cylindrical Lithium-ion Batteries Thermal simulations reveal significant improvements in cooling performance at 3C fast-charging of

Comparison on Thermal Runaway and Critical

Mar 3, 2025 · This review on the critical characteristics of cylindrical batteries under thermal failure and thermal abuse provides a reference for solving

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes.

How to Choose a Cylindrical Lithium Battery

Dec 17, 2024 · Cylindrical lithium batteries are widely used in various applications due to their high energy density, long cycle life, and excellent safety features. These batteries are

A critical review of lithium-ion battery safety testing and

Aug 1, 2023 · The safety of lithium-ion batteries (LiBs) is a major challenge in the development of large-scale applications of batteries in electric vehicles and energy storage systems. With the

6 FAQs about [Cylindrical lithium battery safety]

Are cylindrical lithium-ion batteries safe?

Though cylindrical batteries often incorporate safety devices, the safety of the battery also depends on its design and manufacturing processes. This study conducts a design and process failure mode and effect analysis (DFMEA and PFMEA) for the design and manufacturing of cylindrical lithium-ion batteries, with a focus on battery safety. 1.

Are lithium ion batteries safe?

Major safety concerns for lithium-ion batteries are thermal runaway and explosion. Thermal runaway is a phenomenon where exothermic reactions occur within the cell, leading to a rapid temperature increase, potentially causing the cell to catch fire .

Which cylindrical lithium-ion batteries have the worst consequences?

Among all types of cylindrical lithium-ion batteries, the 21700 exhibits the worst consequence, which is attributed to the adoption of high energy density LiNi 0.8 Co 0.15 Al 0.05 O 2 (NCA) and LiNi x Mn y Co z O 2 (NMC) cathode materials.

What are the OSHA standards for lithium-ion batteries?

While there is not a specific OSHA standard for lithium-ion batteries, many of the OSHA general industry standards may apply, as well as the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). These include, but are not limited to the following standards:

What are the flammability characteristics of lithium ion batteries?

The flammability characteristics (flashpoint) of common carbonates used in lithium-ion batteries vary from 18 to 145 degrees C. There are four basic cell designs; button/coin cells, polymer/pouch cells, cylindrical cells, and prismatic cells. (see Figure 1).

Why do lithium ion batteries have safety vents?

Abstract: Cylindrical Li-ion batteries (cells) typically have safety vents in the positive terminal to enable the release of gases that build up inside the battery and thus help reduce the effects of thermal runaway, including fire and explosion. However, the vents are not always effective, and it is critical to understand why.

Industry Information

- Fuel Energy Storage System

- 600v photovoltaic panel specifications and standard dimensions

- Where in Bosnia and Herzegovina can I buy 80AH lithium battery packs

- European Outdoor Portable Power Supply Factory

- Tripoli battery storage container

- Huawei Central Europe Safe Energy Storage Battery

- Canadian Home Energy Storage

- High quality outdoor power station factory distributor

- Uzbekistan car inverter manufacturer

- Lithium battery inverter

- High quality portable power bank

- 2800 watt 12 volt inverter

- Madagascar energy storage power supply manufacturer

- Bissau Power Storage Project

- Madagascar Authorized Manufacturer of Outdoor Communication Battery Cabinets

- Best high quality solar power unit Seller

- Photovoltaic power inverter direct use

- Iceland energy storage inverter price

- Lithuania energy storage battery customization

- Sanaa Manufacturing Energy Storage Container Company

- How to match solar photovoltaic system

- Haiti Super Aluminum Electrolytic Capacitor

- No 9 lithium battery as outdoor power supply

Commercial & Industrial Solar Storage Market Growth

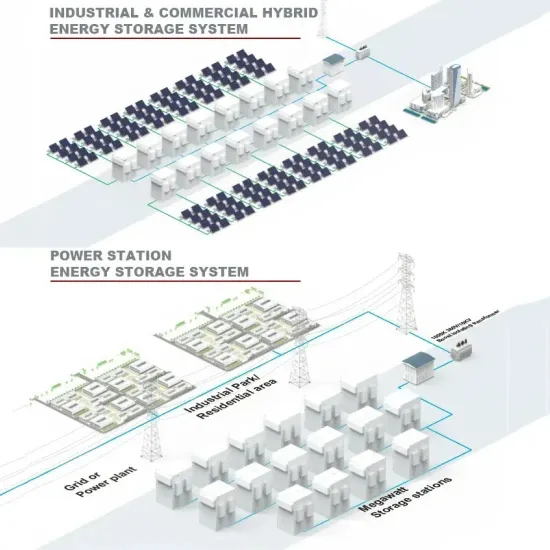

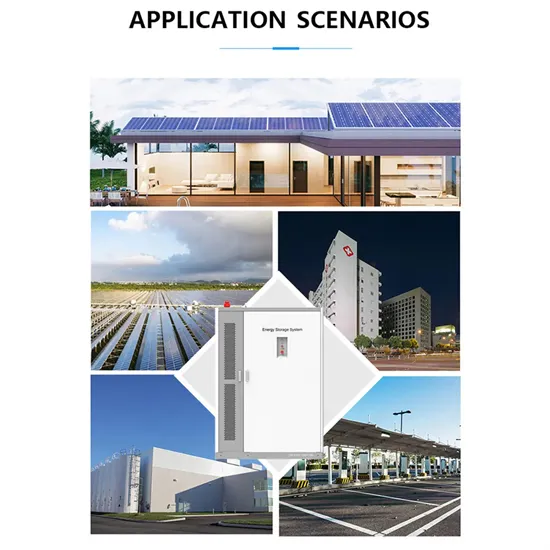

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

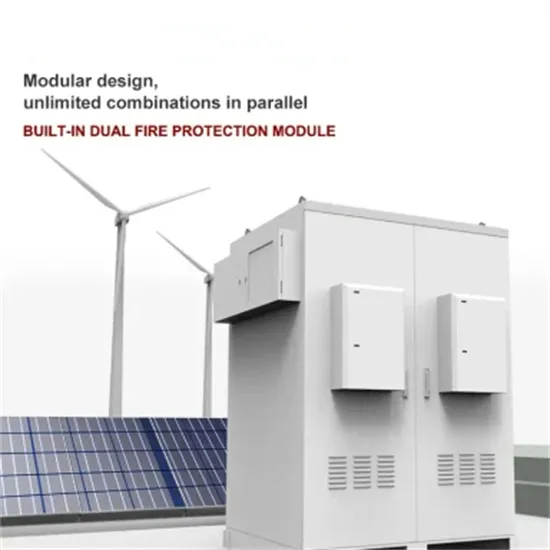

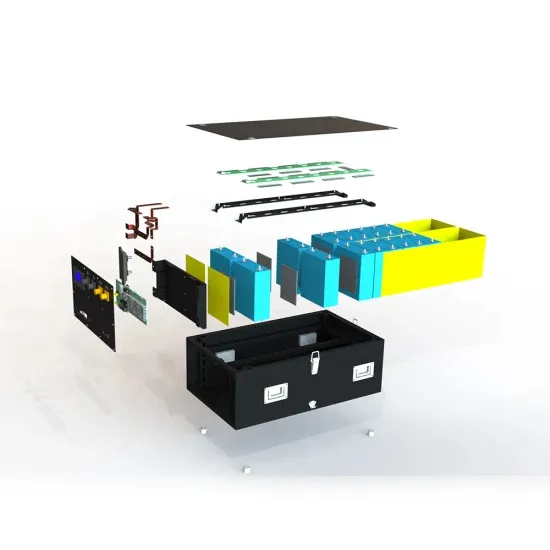

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.