Energy storage cabinet battery production line

How to design an energy storage cabinet: integration and Data collection and analysis: Collect the working data of energy storage cabinets (such as battery voltage, current, temperature,

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Battery capacity cabinet production

How many battery factories will be built in 2022? In total, at least 120 to 150 new battery factories will need to be built between now and 2030 globally. In line with the surging demand for Li-ion

Top 10 Battery Assembly Line Equipment

Mar 23, 2025 · Discover the top 10 battery assembly line factory manufacturer suppliers for 2025. Learn how to select the best equipment for your production

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

Automate battery production with robotics and proven

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

Production process of battery cabinets

Lithium-ion cell and battery production processes Sub-process steps in battery cell production involve a great number of companies that have the know-how for specific production steps and

Lithium battery energy storage cabinet production tutorial

Lithium secondary batteries store 150-250 watt-hours per kilogram(kg) and can store 1.5-2 times more energy than Na-S batteries,two to three times more than redox flow batteries,and about

Battery Production Lines

At BESS (Battery Energy Storage Systems), we are committed to accelerating the global transition toward clean energy by providing cutting-edge solutions for battery production,

Battery production of the future | Bosch Rexroth

As a provider of automation solutions, Bosch Rexroth supports the entire value stream: From electrode and cell production to battery module and pack

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

New Energy Battery Production Line

4 days ago · Xiaowei specialize in the research, development and sales of battery technology (battery production machine) manufacturing processes and

Lithium Battery Formation and Capacity Grading Cabinet

Oct 9, 2024 · China''s battery production capacity grew 56% year-over-year in 2023, reaching 1,200 GWh, with Tier 2 battery manufacturers accelerating automated formation line

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

From Raw Materials to Power Giants: Inside the Large Energy

From Raw Materials to Power Giants: Inside the Large Energy Storage Cabinet Production Line You know what''s hotter than a Tesla battery pack in July? The race to build efficient large

Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

ENERGY STORAGE CABINET PRODUCTION LINE

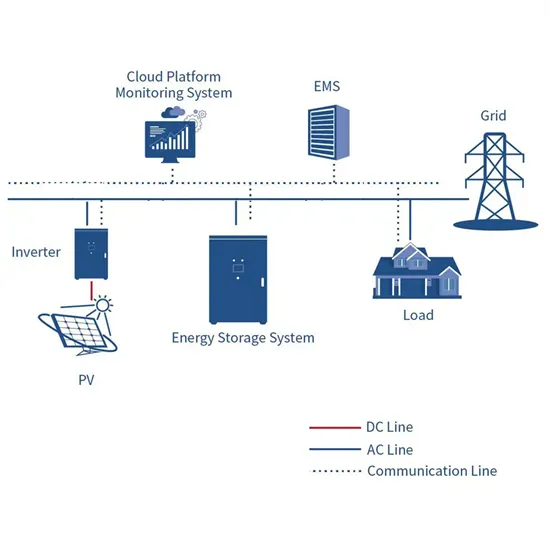

The connected. . Battery Energy Storage System Components. The battery energy storage system illustration below consists of batteries, a battery management system, an inverter,

Automated production of battery cabinets

Battery Cell Formation Turnkey Solution It is a real-time, fast and accurate in line modern production management system with immediate production control, status return, and report

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The industrial and commercial batteries mainly include 280Ah/0.5C Battery Packs, and 100Ah/1C Battery Pack, which can reach a

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Production Line Overview Chisage ESS has been in the field of solar battery for many years and is committed to producing high-quality energy

Electrolyte Diffusion Standing Cabinet for Lithium Pouch Cell

Aug 19, 2025 · Electrolyte Diffusion Standing Cabinet for Lithium Pouch Cell Production Line, Find Details and Price about Vacuum Standing Box Lithium Battery from Electrolyte Diffusion

Battery module production | KUKA AG

KUKA supplies fully automated production line for battery modules to ElringKlinger, systems partner to the automotive industry.

Container energy storage cabinet production line

Aug 6, 2021 · ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and

Battery Assembly Line Design, Build, and Scaling

Our battery assembly line solutions are designed for flexibility and scalability, allowing manufacturers to adapt to evolving production demands. We offer

The battery is like a living entity, we produce

EVE Energy Co., Ltd.The battery is like a living entity, we produce them with uncompromised respect and dignity.

ENERGY STORAGE CABINET PRODUCTION LINE

Assembly sequence requirements for energy storage battery production line We understand the individual assembly steps and requirements that are necessary for high-quality battery

Smart Energy Storage Cabinet Assembly Line-Battery PACK Production Line

A scientific and technological enterprise specializing in the research and development, production and sales of industrial laser processing equipment, has been deeply engaged in the new

Winack: Battery Test System,Battery Cell Production

WinAck Group is one of the China leading suppliers of reliable and competitive battery pack assembly lines for lithium-ion battery modules and battery packs. Production solutions for

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

asecos: ION-LINE safety storage cabinets

Safety storage cabinets for passive or active storage of lithium-ion batteries according to EN 14470-1 and EN 1363-1 with a fire resistance of 90 minutes

Lithium Battery Production Plant,Lithium Battery

Laboratory Pouch Cell Assembly Line For Lithium Battery Fabrication Machine Semi-automatic Laboratory Lithium-ion Battery Assembly Machine for Pouch

Li-Ion battery assembly lines for energy storage

Aug 18, 2025 · BM-Rosendahl offers tailor-made assembly lines designed to streamline the production of ESS batteries. Our solutions are adaptable to

4 FAQs about [Battery cabinet production line site]

What are battery cells made of?

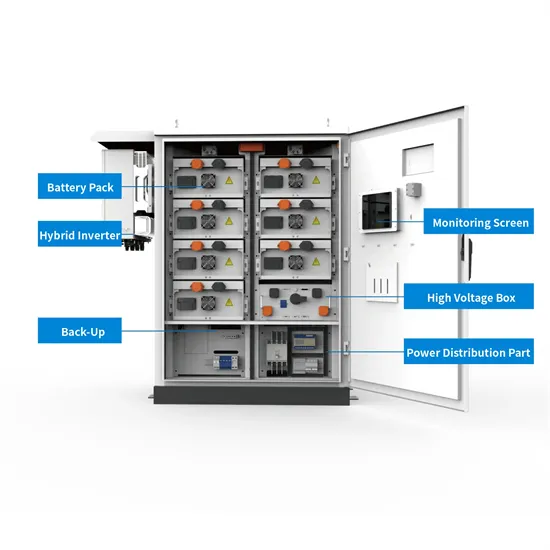

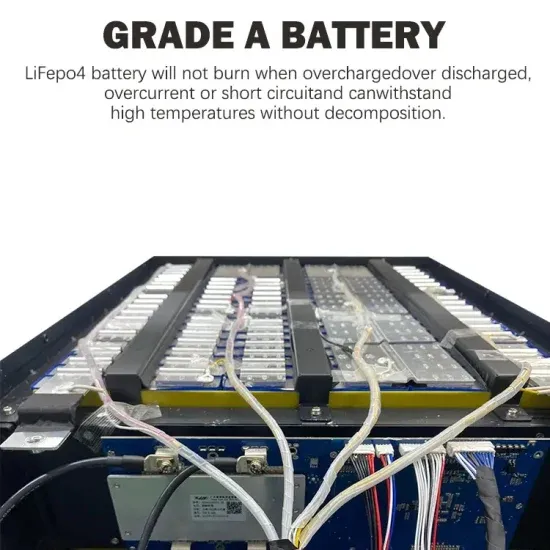

Our battery cells are all made of new A-grade cells, with a single cell voltage of 3.2V, and the current production of battery Pack capacity is mainly 100Ah, 200Ah, and 280Ah. Use steel belts for pressing and packing, form 8 cells into 1 Module module, 2 Module modules into 1 Box Pack, and dissipate heat through ducts and fans.

What type of battery is used in a house?

Household batteries are mainly low-voltage 100Ah, 200Ah, and 300Ah batteries, including 5kWh rack-mounted battery packs, 5-10kWh wall-mounted battery packs, 5-20kWh stacked battery packs, and 15kWh floor-mounted battery packs.

What is the production process for chisage ESS battery packs?

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly, pack testing, and packaging for storage. Now, following in the footsteps of Chisage ESS, our sales engineers are ready to take you on a virtual tour!

Who makes better batteries?

For better batteries, Win & Ack! XIAMEN WINACK BATTERY TECHNOLOGY CO., LTD. For better batteries, Win & Ack! As a provider of turnkey solutions, WinAck Group, together with strong partners, provides the complete solutions for the manufacturing and testing of lithium-ion batteries.

Industry Information

- On-grid and off-grid energy storage batteries

- Price of original battery for communication base station

- Outdoor power supply AC is always on

- Bridgetown Household Photovoltaic Energy Storage Power Station

- What is the working power of a 500W inverter

- 4000w solar inverter for sale in Gambia

- Energy storage equipment price adjustment

- How many volts does a mobile outdoor power supply usually have

- Georgetown Lithium Inverter Price

- Seoul professional custom lithium battery pack

- Podgorica Photovoltaic Energy Storage System

- T-type photovoltaic grid-connected inverter

- The impact of temperature on inverter voltage

- Brasilia Industrial and Commercial Energy Storage Cabinet Factory Price Inquiry

- Azerbaijan solar street light energy storage

- Waterproof and explosion-proof large capacity outdoor power supply

- Is the inverter battery loss serious

- Base station cabinet wind power supply

- Guinea Home Hybrid Inverter

- Double throw breaker in China in Korea

- 48V inverter z production

- Power storage systems factory in Nepal

- How many watts does a 90 volt solar charger have

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

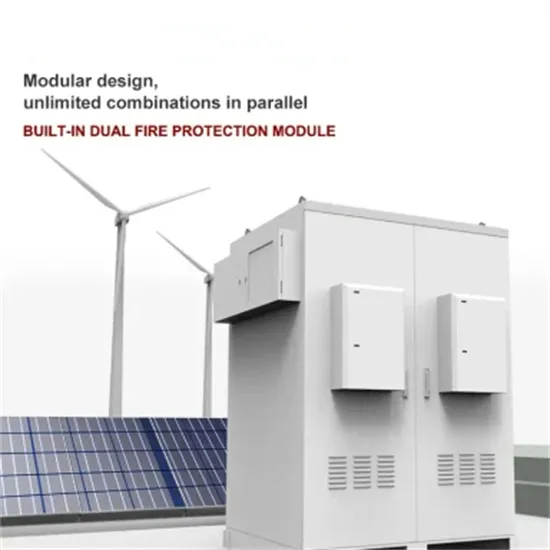

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.