Working Principle of Energy Storage Lithium Battery

How do Lithium battery balancers work? The working principle of lithium battery equalizer monitoring the voltage levels of individual cells within a Li-ion or Li-polymer battery pack and

Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The electrolyte solution in most lithium-ion batteries is highly flammable. Any rupture or internal damage can lead to leakage and ignition, further increasing the need for

Battery energy storage system components

Battery Management System (BMS) Any lithium-based energy storage system must have a Battery Management System (BMS). The BMS is the brain of the

Lithium battery energy storage cabinet principle

Lithium battery energy storage cabinet principle explanation What is a battery energy storage system? A battery energy storage system (BESS) is an electrochemical devicethat charges (or

asecos: ION-LINE safety storage cabinets

Safety storage cabinets for passive or active storage of lithium-ion batteries according to EN 14470-1 and EN 1363-1 with a fire resistance of 90 minutes

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

Assembly diagram of lithium battery energy storage

A battery energy storage system is of three main parts; batteries, inverter-based power conversion system (PCS) and a Control unit called battery management system (BMS). Figure

Lithium Battery Storage & Charging Cabinets

Fire-resistant secure cabinet, specially developed for storage and charging of lithium-ion batteries, as well as the storage of critical batteries. Risk of fire spreading and accelerating is

Principle picture of lithium battery power supply cabinet

Explore cutting-edge energy storage solutions in grid-connected systems. Learn how advanced battery technologies and energy management systems are transforming renewable energy

Principle of lithium battery distribution cabinet

Rely on Wesgar to produce first-class battery enclosures and take care of your unique needs. Our quality custom lithium-ion battery storage cabinets are skillfully fabricated leveraging our 250+

The Ultimate Guide to Lithium-Ion Battery

Mar 21, 2025 · Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and

Review article Review on influence factors and prevention control

Nov 20, 2023 · Highlights • Summarized the safety influence factors for the lithium-ion battery energy storage. • The safety of early prevention and control techniques progress for the

Working Principle of Energy Storage Lithium Battery

A battery energy storage system (BESS), battery storage power station, However it has a lower energy density compared to lithium-ion batteries. Its working principle and cell construction are

Battery cabinet for safely charging lithium-ion

Charge your lithium-ion batteries safely in a battery cabinet | Batteryguard contains battery fires within the safe | European tested and approved

Working Principle of Lithium Battery DC Cabinet

The Principles and Working of DC Current Shunts. DC current shunts play a vital role in various industries involving electrical measurements. These precision devices are designed to

Working principle of lithium battery distribution cabinet

1, lithium battery protection board composition The general lithium battery protection board is composed of a control IC, a MOS tube, a resistance capacitor, and a FUSE, as shown in the

Battery Energy Storage Cabinet Control System Principle:

The battery energy storage cabinet control system principle operates like a symphony conductor - coordinating cells, managing safety protocols, and ensuring your Netflix binge doesn''t crash

Battery cabinets

Charging cabinet or fireproof safety storage cabinet for lithium-ion batteries - the differences In order to clarify the differences between the two types of battery cabinets, the most important

Battery Energy Storage System (BESS) | The

5 days ago · Your comprehensive guide to battery energy storage system (BESS). Learn what BESS is, how it works, the advantages and more with this

Working Principle of Lithium Battery Energy Storage Power Station

A battery energy storage system (BESS) or battery storage power station is a type of energy storage technology that uses a group of batteries to store electrical energy. Battery storage is

Understanding the Lithium

Mar 17, 2025 · A lithium - battery aging cabinet, also known as a battery formation and aging system, is a specialized piece of equipment designed to subject newly manufactured lithium -

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Battery storage cabinets are integral to maintaining the safety and efficiency of lithium-ion batteries. They provide a controlled environment that

The function of the lithium battery energy storage

How Battery Energy Storage Systems Work . Battery Energy Storage Systems function by capturing and storing energy produced from various sources, whether it''''s a traditional power

Working principle of lithium battery distribution cabinet

The type of BESS is related to the electrochemistry or the battery it employs; such systems can employ lithium-ion, lead-acid, nickel-cadmium, sodium-sulfur, and flow batteries. Energy

Working Principle of Energy Storage Lithium Battery Balancer

A battery energy storage system (BESS), battery storage power station, However it has a lower energy density compared to lithium-ion batteries. Its working principle and cell construction are

Working principle of lithium battery safety storage cabinet

Explore cutting-edge energy storage solutions in grid-connected systems. Learn how advanced battery technologies and energy management systems are transforming renewable energy

The working principle of battery swap cabinet and

State of charge for lithium batteries is one of the important parameters of battery management system, and also the basis for charge and discharge control strategies and battery balance.

Working principle of lithium battery pre-charging cabinet

Lithium Ion Battery Cabinet: Safe & Efficient Energy Storage With the rise of electric vehicles, battery cabinets are being used in charging stations to store energy. This setup allows for

Working principle of llvd and blvd in base station power cabinet

IntroductionIn modern communication networks, base stations, as core infrastructure, are crucial for stable operation. The base station power cabinet is a key equipment ensuring continuous

Understanding the Working Principle of Lithium

Feb 17, 2025 · Lithium ion batteries have become a cornerstone in modern technology due to their efficiency, longevity, and light weight. These batteries

What is a Lithium Battery Formation and Capacitance Tester Cabinet

Dec 26, 2024 · Learn what a lithium battery formation and capacitance tester cabinet is. This article provides a detailed introduction to its definition, working principle, significance in the

Working principle of energy storage power station

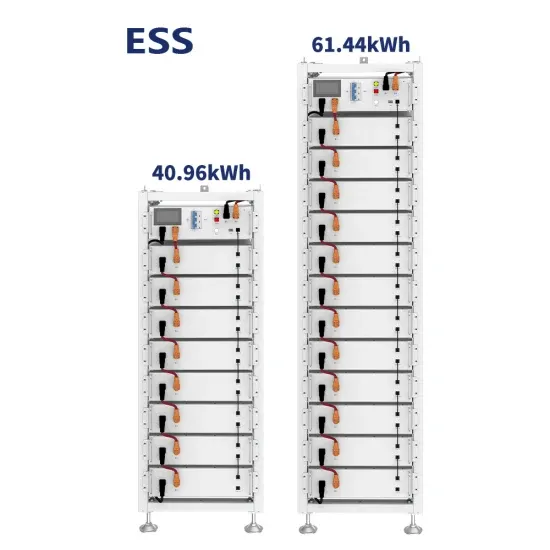

The rack cabinet configuration comprises several battery modules with a dedicated battery energy management system. Lithium-ion batteries are commonly used for energy storage; the

3 FAQs about [Lithium battery station cabinet control system principle]

Can a battery storage system increase power system flexibility?

sive jurisdiction.—2. Utility-scale BESS system description— Figure 2.Main circuit of a BESSBattery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, suc

What is a 4 MWh battery storage system?

4 MWh BESS includes 16 Lithium Iron Phosphate (LFP) battery storage racks arrangedRated power2 MWin a two-module containerized architecture; racks are coupled inside a DC combiner panel. Power is converted from direct current (DC) to alternating current (AC) by tw

What is the value of internal battery resistance?

to the ratio between the full-charge voltage at battery terminals and the internal battery resistance. The value of the internal resistance depends on the cell’s geo etry and construction and on the operating conditions. The common resistance range is 0.5-10 mΩ/cell.From a safety perspective,

Industry Information

- Container finished generator manufacturers

- Huawei Sri Lanka Energy Storage Battery

- House circuit breaker factory in Bahamas

- Base station energy storage case

- Shangneng Energy Storage Project

- Bissau EK Energy Storage 280ah Battery

- 30v monocrystalline photovoltaic panel price

- Energy Storage Cabinet English

- French new photovoltaic panels selling price

- Wholesale c32 circuit breaker in Belgium

- Uganda photovoltaic panel wholesaler

- Tirana photovoltaic energy storage power generation price

- Base station communication power supply construction process

- Malawi s largest cylindrical lithium battery

- Hot sale high quality hybrid inverters Factory

- Several 5G base stations in Benin

- Use of energy storage batteries and batteries

- The importance of green base stations in mobile communications

- Hungary Pecs Customized Outdoor Power Supply Manufacturer

- Small Industrial Solar Power Generation System

- Solar large flow circulation pump

- High quality din rail breaker in Bangkok

- Distribution breaker for sale in Vietnam

Commercial & Industrial Solar Storage Market Growth

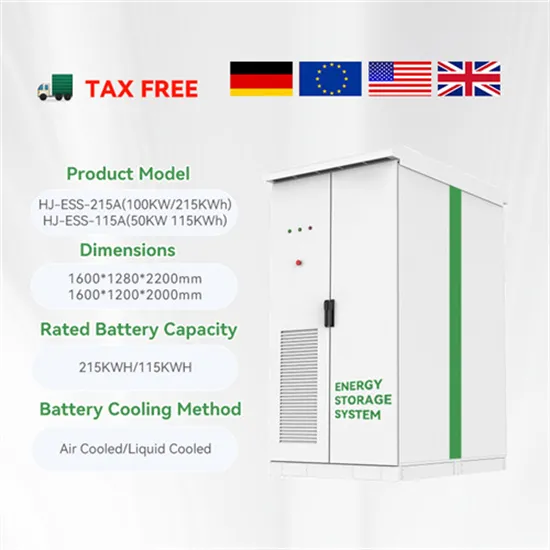

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.