Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Various approaches to securing a battery cabinet include frames or straps under the raised floor. Under-floor frames are subject to the same

Installation And Commissioning

Oct 18, 2016 · The ventilation requirements for battery rooms, cabinets or compartments are based on the required reduction of the concentration of hydrogen generated during charging

Dynamic mechanical behaviors of load-bearing battery

Sep 1, 2024 · To better illustrate the performance of the integrated load-bearing battery structures and facilitate lightweight design, two additional constructions were designed for comparison:

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

CellBlock Battery Cabinets Installation Instructions

Jul 15, 2024 · CellBlock Storage Cabinets are a superior solution for the safe storage of lithium-ion batteries and devices containing them. The cabinet shelves provide fire extinguishing

NPFC Series Product Manual 48NPFC100 Lithium Battery

Nov 4, 2024 · 2. Product Introduction 48NPFC100 lithium battery pack is an advanced product developed according to the requirements of new backup power supply for communication

Installing Parallel Cables (Third-Party Power System)

4 days ago · Otherwise, short circuits will occur. During battery installation, ensure that the positive and negative battery terminals are correctly connected to prevent reverse polarity.

Battery cabinet load-bearing bracket production drawings

Battery cabinet load-bearing production drawings bracket ndards of Mercedes-Benz bus are considered for analysis. Stress and deformation values sts, numerical simulations, and finite

Eaton 93PM Integrated Battery Cabinet-Large and Large

Mar 31, 2025 · Figure 12 shows the location of the battery breaker in the 93PM Integrated Battery Cabinet-Large or 93PM Integrated Battery Cabinet-Large High Rate (432V). Figure 13 shows

Battery cabinet bracket and load-bearing frame

Optimization design of battery bracket for new energy vehicles Serving as the primary component responsible for carrying and protecting the power battery, the battery bracket fulfills

Load-bearing strengthening in the machine

When the weight of the cabinet, air conditioning, ups and other equipment is larger than the floor load, in order to ensure the safety of the building itself and

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

Battery cabinet load-bearing design

attery Cabinet is a total solution. Cabinet, batteries and auxilliary components from a single source; Complete EnerSys factory service from battery sizing to installation and

IntraPack

May 28, 2025 · STEPS FOR BATTERY CABINET INSTALLATION PROCEDURE. 1.TO HELP PREVENT DAMAGE, ALL PANELS FROM ALL BATTERY CABINETS SHOULD BE

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

(Optional) Installing a Battery Cabinet Top Frame

Secure the top frame. Use four M8x20 screw assemblies to secure the top frame to the cabinet, as shown by (3) and (4) in Figure 6-6. Install two M5x10 tapping screws at the front of the top

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Case study-Outdoor Battery Cabinet

Aug 30, 2023 · These cabinets are an essential component in any outdoor electrical installation, providing the reliability and durability needed to keep

Battery Cabinets | Racks | Heavy Duty | Singapore

Aug 19, 2025 · Singapore based manufacturer of Electronic Enclosures, Outdoor Cabinets, Network Racks, Gas Cabinets, Battery Cabinets, Digital Signage Enclosures and Kiosks, Ipad

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Read these instructions carefully and look at the equipment to become familiar with it before trying to install, operate, service or maintain it. The following safety messages may

Installation Instructions for the LifeStartrM AED Cabinets

Dec 11, 2013 · 2 ame in above, below and at both sides of the cabinetopening. Note: On load bearingwalls, the studs must be doubled on eitherside of the cabinettub. lf a stud mustbe cut to

Battery Pack Structural Beams: Load-Bearing Components

Aug 6, 2025 · Discover the crucial role of battery pack structural beams in electric vehicles, focusing on their impact on safety, efficiency, and performance. This article explores the

Battery cabinet installation construction process

Mounting mechanism - they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box

AED Cabinet

Apr 22, 2014 · load-bearing header and install it above the cabinet tank. Place cabinet in position and anchor the cabinet using the convenient pre-drilled holes in the cabinet sides.

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

BATTERY PACK | Lithium battery pack frame structure design

In order to facilitate installation and maintenance, the load-bearing frame is generally divided into an upper frame and a lower frame. The lower frame mainly carries components and bears

Designing the Heart of Electric Vehicles: The

Nov 4, 2023 · Strength: While not as load-bearing as the lower frame, the upper frame must still possess sufficient strength to protect the battery components.

Method Statement for UPS System Installation

Connect the cable for the temperature sensor of the battery cabinet between terminals XT1.1 andXT1.2 of the UPS terminal block (refer figure below)

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

电池安装桁架工装快速指南 Battery Installation Truss

Oct 11, 2023 · 电池安装桁架工装快速指南 Battery Installation Truss Engineering Installation Kit Quick Guide 文档版本:02 Issue: 02发布日期:2022-03-10 Date: 2022-03-10 华为技术有限公司

Eaton 93PM Integrated Battery Cabinet-Small Welded

Mar 29, 2025 · The battery detect signal wiring from the battery cabinet must be connected to a programmed UPS building alarm in the 93PM (480V) UPS and to CN8 in the 93PM-L (208V)

Portal steel frame installation: 11 Detailed Process

4 days ago · The portal steel frame structure is widely used in large buildings, such as industrial plants, warehouses, stadiums, etc., because of its simple

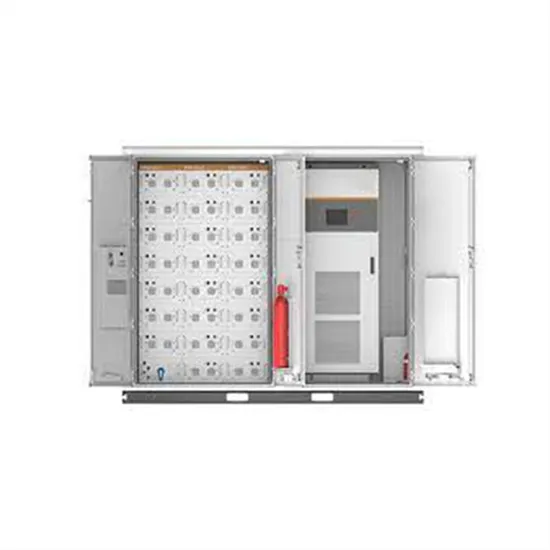

Battery Enclosure | Vertiv

A high protection class battery cabinet that can be applied as standalone or extension of outdoor power system. The system integrates temperature control and ventilation system, heater

Battery cabinet load-bearing bracket installation picture

Installing bottom brackets like a boss – Kogel Bearings Pro tip: radial ball bearings, which are used in most bottom brackets, are designed to run without any side load. Zero. None. Tighten

Key Considerations for Installing a Lithium Battery Cabinet

Installing a lithium battery cabinet like Pytes'' V - BOX - OC needs attention to various factors. Space, environment, accessibility, security, foundation, electricals, and ventilation are crucial

BATTERY PACK | Lithium battery pack frame structure design

NIO In order to facilitate installation and maintenance, the load-bearing frame is generally divided into an upper frame and a lower frame. The lower frame mainly carries components and bears

Battery Pack Structural Beams: Load-Bearing Components

Aug 6, 2025 · These beams serve as essential load-bearing components, providing support and stability to the entire battery enclosure while also connecting the battery pack to the vehicle''s

6 FAQs about [Battery cabinet load-bearing frame installation]

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

What are the battery cabinet external wiring requirements?

The battery cabinet external wiring requirements are shown in Tables D and E. NOTE 1:1All specified wire sizes are 90 C rated copper minimum. NOTE 2:Replace with same type and number of original battery. Mixing battery letter designation and or sizes will damage equipment and void warranty.

How do you attach a battery cabinet to a field kit?

A flat bracket joins the top of the cabinets and a larger flat bracket joins the cabinets at the bottom. The small flat bracket is attached to the cabinet tops first. Remove the left‐hand and right-hand screws from the adjacent top door hinges of the battery cabinets. Locate the small flat bracket from the field kit.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

Industry Information

- Offshore wind power energy storage cabinet outdoor power station price

- What are the energy storage base stations in Central Asia

- Cabinet battery cells as energy storage batteries

- 4000w solar inverter for sale in Tunisia

- 200kw energy storage profit model

- Where can I find lithium battery energy storage cabinets in Southern Europe

- 5kw sunsynk inverter in China in Slovakia

- Pole mounted circuit breaker in Nairobi

- Relationship of inverter DC voltage

- Communication base station power generation safety

- Caracas Solar Energy Storage Container Specifications

- Battery cabinet and distribution cabinet outdoor site

- Photovoltaic curtain wall investment benefits

- 24v2000va inverter

- Electricity introduction project for communication base stations

- Dominica lithium battery energy storage project

- High voltage breaker for sale in Johannesburg

- Prospects for the development of power storage

- Managua lithium energy storage power supply sales price

- Solar water pump manufacturer in Mumbai India

- Battery pack smart factory mes system quotation

- China Mobile Base Station Equipment Power Supply

- Energy Storage Large Battery Standard

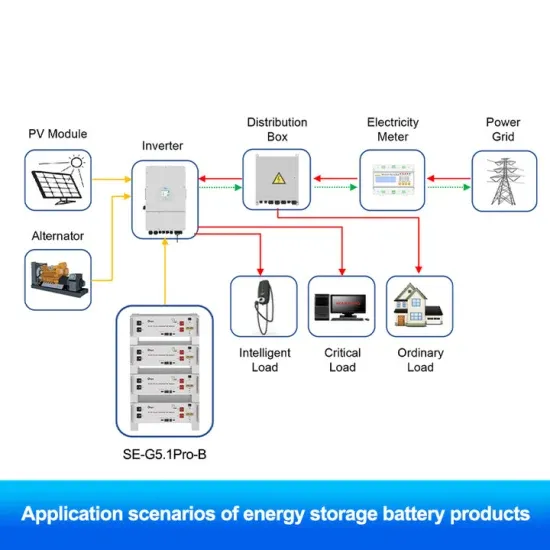

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.