Testing in the Battery Production Line: Do''s and Don''ts

Jan 18, 2024 · Do you need support on what is best practice for testing batteries in the production line and how to avoid unnecessary problems? Roy Hali will look at the pitfalls of using

End-of-Line Vehicle Battery Testing Systems | HORIBA

End-of-Line Battery Testing Evaluator EOL: End-of-Line Battery Testing Systems Addressing the advanced needs of modern battery production processes, HORIBA offers the Evaluator End-of

Production & Testing Solutions Battery & EV Requirements

Apr 11, 2025 · Our Production and Environmental simulators test and assess the quality, durability and performance of batteries to make sure they meet your exacting specifications and

DeepL翻译:全世界最准确的翻译

1 day ago · 即时翻译文本&完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。

Chroma Battery Test & Automation Solutions

The BMS and the battery pack end of line test system can be widely used in battery pack production lines, providing a programmable software platform

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the comprehensive process of lithium-ion battery assembly, detailing each step from cell grading to final pack testing.

Better and Easier Setup For Production Line

Jul 13, 2017 · The hipot test is usually a 100% production line test and can be performed using either an AC or a DC voltage. Fig. 1: The basic hipot setup. A

Apr 21, 2025 · TAICO lithium battery production process analysis: fully automated production lines, stringent testing and industry-leading advantages In the lithium battery industry, the

Automate battery production with robotics and proven

Each individual component is repeatedly tested during the battery production process, culminating in the end-of-line test of the battery. In addition to the leak test, the battery systems undergo

How is the battery cabinet production line for microgrid

Control of a combined battery/supercapacitor storage system for A microgrid is a controllable local network, comprising distributed generation sources, loads, and energy storage systems. A

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Battery cabinet installation production line process

Production Line Guide | CHISAGE Battery Pack Process Flow The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code

End-of-Line Vehicle Battery Testing Systems | HORIBA

Addressing the advanced needs of modern battery production processes, HORIBA offers the Evaluator End-of-Line (EOL) system series. This series caters to a wide spectrum of

Design of cubic battery cabinet production line

The pack line process consists of three main phases: production, assembly, and packaging. The pack is a complex system comprising battery packs, shunts, soft connections, protective

Battery Test Chambers for Comprehensive

5 days ago · What Is a Battery Test Chamber? Battery test chambers simulate the most intense real-world conditions your cells are likely to encounter,

用于工业化过渡和工艺验证的锂电池中试生产线

我们的中试规模锂电池生产线专为希望过渡到工业规模生产的企业而设计。 该生产线采用半自动化方法和全面的质量控制,是工艺放大验证、批量试产的理想选择。

Battery Production | AVL

Aug 18, 2025 · Test systems to ensure quality and safety for battery producers. End of Line (EOL) testbeds with reduced footprint, optimized power consumption, and advanced methods for

Battery Test Chambers | PGC

Battery test chambers from BINDER are ideal for aging, performance, and stress testing in quality assurance and battery production. To ensure maximum safety, all the chambers in the LIT MK

Battery cabinet assembly line safety production

Assembly lines for battery modules | Module production of battery systems. AKE technologies represents the system partner in the field of assembly of e-mobility components for its

What is battery aging cabinet and China top 5

Jun 14, 2023 · This article sorts out the top 5 battery aging cabinet companies in China for your reference, including CPET, Benice, ATSTECH, Wangdafu and

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Users Guide to Hipot Testing

May 31, 2022 · Hipot ("high potential") electrical safety testers produce high voltage to perform dielectric withstand and insulation resistance tests. This

Top 10 Battery Test Equipment Brands: Comparison and

Feb 8, 2025 · Top 10 Battery Test Equipment Brands: Comparison and Selection Guide Like humans, everything in the electrical and electronics world needs a power supply to perform its

Evolving Battery Technology

As battery technology evolves, so the process of testing it all becomes more complex, as Peter Donaldson discovers. End-of-line (EOL)

Cube battery cabinet assembly production line

Production line of Silent Power Off-Grid Cabinets Production line of Silent Power Off-Grid Cabinets. Silent Power cabinet is the first solar photovoltaic cabinet that is delivered fully

Battery cabinet production line process

Process Technology1.Cell Sorting Firstly, we carry out the initial inspection of the battery cells, using OCV to measure whether the voltage is in the same gear and eliminate the defective

The Last Mile – End-of-Line Test for Batteries

Mar 16, 2021 · The Last Mile – End-of-Line Test for Batteries Quality assurance in industrial production processes gets more and more important. An increasing num-ber of battery

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

Outdoor Cabinets – Karmet Makina

Outdoor DC Battery Cabinet They are Outdoor DC power (battery) cabinets in the usage areas of GSM Vendor and operators. It is in the class of system cabinets protected against external

Battery module production | KUKA AG

KUKA supplies fully automated production line for battery modules to ElringKlinger, systems partner to the automotive industry.

Driving the Production of Lithium-ion Batteries

EV lithium-ion battery production lines are largely automated to achieve narrow thresholds. To assess quality and achieve precision, these automations

battery capacity test and analyze for battery pack production line

May 28, 2025 · A lithium battery capacity cabinet is a device that can test and analyze battery capacity. It can detect the actual capacity of the battery and classify the battery into different

Energy storage cabinet battery production line

How to design an energy storage cabinet: integration and Data collection and analysis: Collect the working data of energy storage cabinets (such as battery voltage, current, temperature,

Understanding the Lithium

Mar 17, 2025 · In large - scale battery manufacturing plants, lithium - battery aging cabinets are an essential part of the production line. They are used to age batteries before they are shipped to

6 FAQs about [Battery cabinet production line test]

What is end of Line battery testing?

Test systems to ensure quality and safety for battery producers. End of Line (EOL) testbeds with reduced footprint, optimized power consumption, and advanced methods for efficient testing of factory-produced battery modules and packs. As the demand for electrified systems and products grows, the importance of batteries has significantly increased.

Why do you need a battery test system for production?

From modules to battery packs, this test system enables comprehensive battery testing in production. The system supports both Conformity of Product (CoP) and Quality Assurance (QA) testing. Why You Need a Battery Test System for Production? To meet the demands of OEMs and their customers, batteries must combine performance with durability.

What makes the cell-to-battery assembly line unique?

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability.

What are the tests for pack batteries?

Our testing of pack batteries mainly includes insulation withstand voltage test and charge/discharge test.

What is the AVL battery TSTM end of line?

To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End Of Line. From modules to battery packs, this test system enables battery testing in production. The system covers Conformity of Product (CoP) and Quality Assurance testing.

What is the final stage of a battery test?

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety.

Industry Information

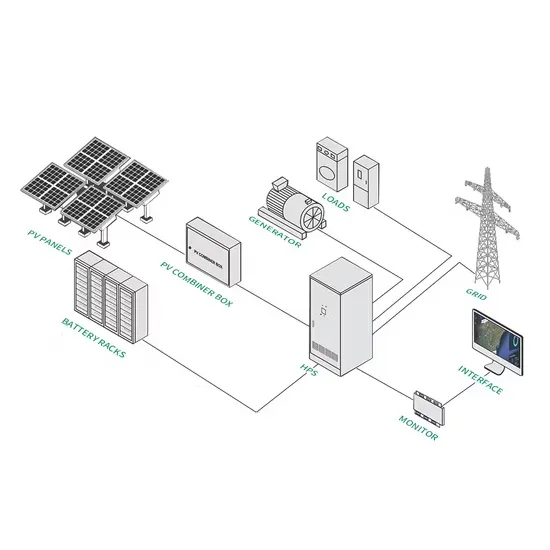

- United Township Energy Storage Photovoltaic Power Station

- Best wholesale c20 circuit breaker Factory

- Mobile generator power station manufacturers

- Al jameel switchgear in China in Uruguay

- Energy storage cabinet liquid cooling system circulation system

- Credit for energy storage projects

- Argentina Cordoba Emergency Portable Power Wholesale

- China high quality outdoor breaker producer

- European Mobile Energy Storage System

- Photovoltaic solar glass installation

- Energy storage battery decay rate

- Myanmar s new solar energy system

- What is the new energy storage

- 1 2 kw solar inverter factory in Australia

- Indonesia UPS Uninterruptible Power Supply 50K Price

- Photovoltaic power station 30KW off-grid inverter

- Thickness of photovoltaic panel glass

- Democratic Republic of Congo idle outdoor communication power supply BESS

- 15W Solar Cell

- Communication base station battery energy storage system machine room manufacturer direct sales

- Kenya and lithium iron phosphate battery pack life

- Senegal 500mwh energy storage power station

- South Africa generator container

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.