How to contain your lead acid batteries

Jul 16, 2018 · Dolav provided us with some information regarding how to store lead acid batteries using their eco-friendly container. A container for lead-acid

How To Store And Manage Lead-Acid Batteries?

Aug 20, 2024 · Storage management of lead-acid batteries is crucial to ensure battery performance, extend service life and prevent safety accidents. The following are some key

Lead-Acid Battery Cabinet

If the configured batteries can be placed in four or fewer battery cabinets, it is recommended that battery cabinets be deployed inside the smart module (smart module A).

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · In addition, cabinets with VRLA batteries have a separate requirement to identify the details of the battery system, electrical, chemical and fire hazards. Remember New York

Battery Safety – Using the BTS Container

Aug 18, 2025 · Battery chemistries should not be mixed, so if you are using the BTS Container to store used lead acid batteries you should not include other

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · Whether leveraging an existing cabinet through a like-for-like replacement or opting for a new UPS battery cabinet or rack altogether, you''ll need to consider connector

Hydrogen Management in Battery Rooms

2 days ago · Vented Lead Acid (VLA) and vented Ni-Cad (Ni-Cad) batteries are either fully vented or partially recombinant battery types (Figure 1). They are

6 ways to boost lead acid battery capacity

So, let''s dive into some relatable, easy-to-follow best practices for lead acid battery storage. 1. Choose the Right Environment. Imagine this: after a long day of working on your solar project,

How to modify the original lead-acid battery

To recondition a lead acid battery, you need to remove the lead sulfate buildup from the plates and restore the electrolyte solution. This process involves cleaning the plates,

NFPA 70E Battery and Battery Room Requirements | NFPA

May 24, 2021 · Safety requirements for batteries and battery rooms can be found within Article 320 of NFPA 70E

How to calculate that your power system is

Jul 13, 2022 · Gassing and Ventilation of Lead-acid Batteries in Standalone Power Systems. How to calculate that your power system is adequately

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Understanding Battery Storage Cabinet Components and Benefits Key Components of a Battery Storage System A battery storage system is a sophisticated unit

Lead Acid Battery Cleaning Techniques – DIY Battery

Lead Acid Battery Cleaning Techniques When it comes to maintaining our gadgets and gizmos, we often overlook one important component: the lead acid battery. Whether it''s in your car, a

battery cabinet,battery storage cabinet,battery

EverExceed designs customized battery cabinets / racks for individual batteries. The cabinet or racking system can be specified to accomodate any battery

Lead-Acid Batteries

Jan 22, 2025 · This is especially true in areas where lead-acid batteries'' dependability and price are highly appreciated. Lead-acid battery performance

How to modify the battery cabinet for lead-acid batteries

How do you restore a lead-acid battery that doesn''t hold a charge? To restore the capacity of a lead-acid battery that is not holding a charge, you can use a desulfator device. This device

The Science Behind the Spark: How Lead Acid

Apr 1, 2025 · The Science Behind the Spark: How Lead Acid Batteries Work Lead acid batteries are a marvel of chemistry and engineering, providing reliable

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

A Complete Guide to Lead Acid BMS

Sep 24, 2024 · Conclusion In summary, a Lead-Acid BMS is an essential tool for anyone relying on lead-acid batteries, providing safety, reliability, and

System Batteries, Sealed Lead-Acid with Applications

Jan 17, 2025 · Fire Alarm Control Panel Accessories System Batteries, Sealed Lead-Acid with Applications Reference for Battery Cabinets, and Battery Cabinets with Charger

White Paper Disposal of Lead-Ac

Jan 4, 2022 · The objective of this paper is to review the regulatory, legal and financial considerations of proper decommissioning, removal and disposal of Wet Cell and Valve

A Guide To Lead-Acid Batteries

Dec 5, 2020 · Structure and Operation Most lead-acid batteries are constructed with the positive electrode (the anode) made from a lead-antimony alloy with lead (IV) oxide pressed into it,

What are the OSHA Requirements for Battery

Oct 16, 2023 · What are the OSHA Requirements for Battery Storage (2023) Last Updated: 16 October 2023 OSHA requirements for battery storage are

Battery venting

5 days ago · Battery venting is a critical safety feature in batteries that prevents the build-up of pressure and gas. Different types of batteries, like lead-acid

VRLA battery cabinets

3 days ago · Function VRLA (Valve Regulated Lead Acid) batteries are lead batteries with a sealed safety valve container for releasing excess gas in the event of internal overpressure.

Silent Power Cabinet For GEL & AGM Lead Acid

Metallic enclosure for safe installation of AGM and GEL batteries. It fits all deep-cycle solar batteries 105Ah, 200Ah, 250Ah, 300Ah. The Silent Power (SP) will

COMPREHENSIVE GUIDE TO Reporting Batteries

Oct 6, 2023 · Background Lead-acid batteries are commonly used to power cars, industrial trucks, such as forklifts or lift trucks, and even to serve as backup power sources to cell towers.

Lead acid battery cabinet,Battery Rack,battery stands racks

EverExceed designs standard and customized all kinds of battery cabinets / racks for all kinds of lead acid batteries, such as tubular flooded batteries, sealed Modular Max Range VRLA

Storage battery requirements

Jan 27, 2017 · The batteries associated with UPS systems represent an unusual hazard. Remember that lead-acid batteries are devices that store incredible

How To Store Lead Acid Batteries

May 6, 2024 · Learn the best practices for storing lead acid batteries in this comprehensive articles. Discover how to extend the lifespan of your batteries

Lead acid battery production technology

Mar 15, 2024 · If ABS battery slots are used for valve-controlled sealed lead-acid batteries, they need to be bonded with special adhesives. Main control parameters of battery assembly: bus

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

6 FAQs about [How to modify the battery cabinet for lead-acid batteries]

What is a lead-acid battery?

Lead-acid battery is a type of secondary battery which uses a positive electrode of brown lead oxide (sometimes called lead peroxide), a negative electrode of metallic lead and an electrolyte of sulfuric acid (in either liquid or gel form). The overall cell reaction of a typical lead-acid cell is:

Can a lead-acid battery be added to a negative electrode?

Adding carbon on the negative electrode reduces this problem but this lowers the specific energy. Lead-acid batteries are the most widely used energy reserve for providing direct current (DC) electricity, primarily for uninterrupted power supply (UPS) equipment and emergency power system (inverters).

Do lead-acid batteries release hydrogen gas?

It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately ventilated to prohibit the build-up of hydrogen gas. During normal operations, off gassing of the batteries is relatively small.

What are the three major contributors to lead-acid battery chemistry?

The three major contributors to Lead-acid battery chemistry are lead, lead dioxide, and sulfuric acid. Unfortunately pure lead is too soft to withstand the physical abuse; about 6% antimony is added to strengthen it.

What is a flooded lead-acid battery?

Vented Lead-acid Batteries are commonly called “flooded” or “wet cell” batteries. These have thick lead-based plates that are flooded in an acid electrolyte. The electrolyte during charging emits hydrogen through the vents provided in the battery.

How much weight can a lead-acid battery carry on a floor?

Due to the weight of lead-acid batteries, column and floor loading can quickly become a problem. Flooded wet cell batteries racked two or three tiers high in a limited floor area can easily impress a 250 to 450 lbs/sq-ft floor loading on the structural floor which will transfer to column and footers.

Industry Information

- Proportion of grid-connected suppliers of communication base station inverters

- How many watts does a solar light 247 have

- Wellington PV container substation price

- Flywheel energy storage system configuration

- Cambodia Professional RV Solar System

- High quality hybrid inverters in Romania

- Solar Street Light Photovoltaic Panel

- Where can I buy outdoor power supplies in Sofia

- Baghdad battery energy storage project construction

- Energy storage equipment peripheral equipment

- Communication integrated base station

- Liechtenstein Energy Storage Photovoltaic Combiner Box Sales

- China solar circuit breaker factory distributor

- Mainstream energy storage lithium battery

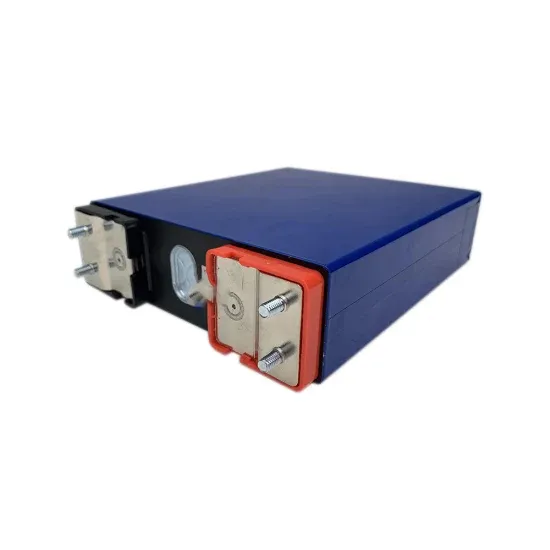

- Industrial and commercial energy storage battery types

- Photovoltaic grid-connected single-phase inverter

- Battery cabinet load-bearing frame installation

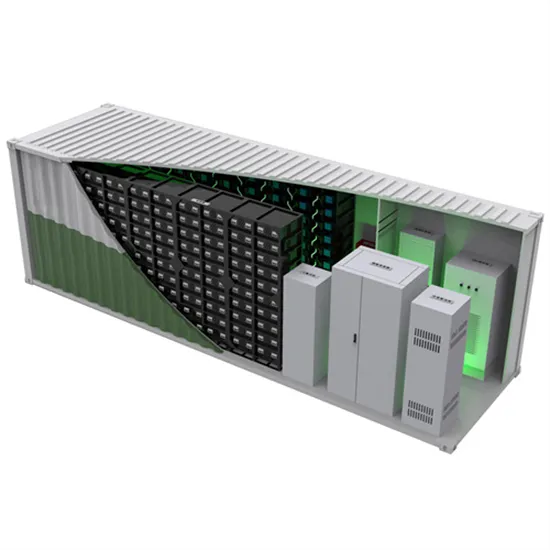

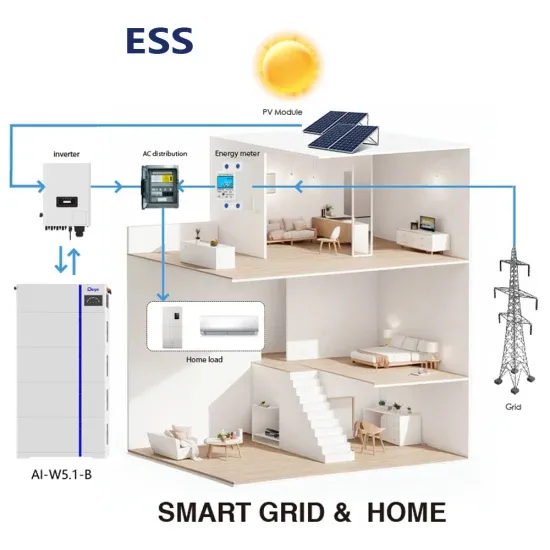

- What are the functions of energy storage container power supply

- Perc and n-type components

- Full set of solar power supply system

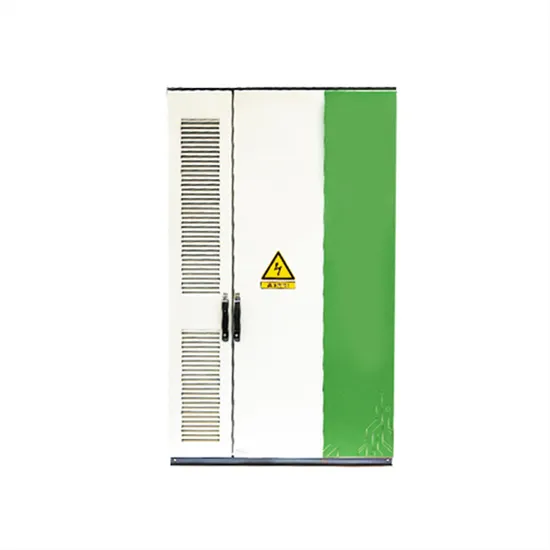

- Lithium Energy Storage Cabinet Company

- How many v batteries are needed for home solar energy storage

- Seychelles communication base station electrical maintenance

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.