Research and test verification on simulation technology of

The heat dissipation of the motor and its components is crucial for the safe operation of the flywheel energy storage system. This is a critical scientific and technical problem that needs to

Flywheel energy storage rotor heat dissipation mechanism

A heat dissipation mechanism and flywheel energy storage technology, which is applied in the direction of electromechanical devices, mechanical energy control, magnetic circuit rotating

Magnetic suspension flywheel energy storage system using

The invention relates to a magnetic suspension flywheel energy storage system using a liquid cooling heat dissipation technology, which comprises a system shell, a motor rotor, a magnetic

Flywheel energy storage rotor heat dissipation

A flywheel energy storage and heat dissipation system technology, which is applied to systems for storing electrical energy, controlling mechanical energy,

US20030066381A1

Featured are a device, system and method for dissipating at least some heat energy generated by one or more heat generating components of a flywheel energy storage system (FESS). The

CN218206936U

Present flywheel energy memory is the whole encapsulation of motor with whole flywheel and drive flywheel in the cavity, and this leads to the produced a large amount of heats of the

CN113364185A

The invention can solve the problem of difficult heat dissipation of the rotor in the flywheel energy storage system under the vacuum condition, avoids adopting an external liquid pump system

Overview of the motor-generator rotor cooling

Abstract: Motor-generators (MGs) for converting electric energy into kinetic energy are the key components of flywheel energy storage systems (FESSs).

Numerical study of jet impingement cooling methods for improving heat

Aug 1, 2024 · Flywheel energy storage systems (FESS) have garnered a lot of attention because of their large energy storage and transient response capability. Due to the limited space and

Flywheel energy storage and heat dissipation method

What is a flywheel and how does it work? A flywheel is an onboard energy recovery and storage systemthat is durable,efficient,and environmentally friendly. It works by storing energy in a

The most complete analysis of flywheel energy

Aug 23, 2023 · Flywheel energy storage is a mechanical storage device that realizes the mutual conversion and storage of electrical energy and

Optimising flywheel energy storage systems for enhanced

Jun 1, 2025 · Flywheel energy storage systems (FESS) can recover and store vehicle kinetic energy during deceleration. In this work, Computational Fluid Dynamics (CFD) simulations

Optimising flywheel energy storage systems for enhanced

Jun 1, 2025 · Concerns about global warming and the need to reduce carbon emissions have prompted the creation of novel energy recovery systems. Continuous braking results in

Heat energy dissipation device for a flywheel energy storage

Featured are a device, system and method for dissipating at least some heat energy generated by one or more heat generating components of a flywheel energy storage system (FESS). The

Numerical analysis of a flywheel energy storage system

May 15, 2025 · Flywheel offers an onboard energy recovery and storage system which is durable, eficient, and environmentally friendly. The flywheel and the housing surface temperatures can

Research on Taylor Vortex in the air-gap of flywheel energy storage

May 1, 2025 · Flywheel energy storage systems (FESSs) are integral to renewable energy integration in power grids, effectively mitigating wind and solar curtailment while stabilizing grid

Analysis and design on stator heat dissipation of motor in flywheel

This simple and efficient design method provides a reference for the development of stator cooling systems for flywheel energy storage applications. Key words: flywheel energy storage, motor

Flywheel energy storage and energy dissipation

The flywheel energy storage systems can be used for stability designin high power impulse load in independent power systems [187,188]. A combined closed-loop based on the genetic

Design of flywheel energy storage device with high

Jun 28, 2025 · In this paper, a multistage flywheel energy storage device was designed to improve the energy density and power density of the flywheel, and the parameters of both first

飞轮储能装置电机温度场仿真技术研究及试验验证

Mar 18, 2024 · The heat dissipation of the motor and its components is crucial for the safe operation of the flywheel energy storage system. This is a critical

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

CN118040963A

According to the flywheel energy storage device and the flywheel energy storage system, radiation heat dissipation and liquid cooling heat dissipation are combined, and the heat

CN216390739U

The utility model provides a flywheel energy storage rotor heat dissipation mechanism and a flywheel energy storage system, wherein the heat dissipation mechanism comprises a first

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

Overview of the motor-generator rotor cooling system in a flywheel

Abstract: Motor-generators (MGs) for converting electric energy into kinetic energy are the key components of flywheel energy storage systems (FESSs). However, the compact diameters,

CN108900039B

The invention discloses a flywheel energy storage rotor vacuum heat dissipation system which mainly comprises an evaporation device, a condensation device and a loop pipeline. The

Jet impingement cooling in rotating flywheel energy storage

Jul 1, 2025 · As an innovative energy storage technology, flywheel energy storage systems (FESS) have garnered substantial research interest in recent years, particularly regarding their

Analysis and design on stator heat dissipation of motor in flywheel

To address the stator cooling challenges in the 500 kW flywheel energy storage motor, a spiral water jacket was installed on the outside of the stator. By simplifying the heat source and heat

The most complete analysis of flywheel energy

Aug 23, 2023 · This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Flywheel Energy Storage

Of this, 17% is recoverable regenerative braking energy. However, the regenerative energy recovery in current urban rail systems is generally

CN215419967U

The utility model relates to the technical field of flywheel energy storage systems, and particularly discloses a heat dissipation structure for a flywheel energy storage unit. The utility model can

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

How to Improve the Performance of Flywheel

The performance of flywheel energy storage is the main topic of the article. We will provide some solutions to improve the performance of flywheel energy

flywheel energy storage and heat dissipation method

Flywheel energy storage rotor heat dissipation mechanism A heat dissipation mechanism and flywheel energy storage technology, which is applied in the direction of electromechanical

Flywheel energy storage and heat dissipation

heat dissipation In this research, the effects of the heat pipes arrangement as a passive cooling system in an electric motor for the flywheel energy storage application were analysed. Two

Flywheel energy storage device with novel structure for

Abstract The invention provides a flywheel energy storage device with a novel structure for realizing bearing lubrication and heat dissipation by using gas circulation. The device mainly

6 FAQs about [Flywheel energy storage and heat dissipation device]

Can flywheel energy storage systems recover kinetic energy during deceleration?

Flywheel energy storage systems (FESS) can recover and store vehicle kinetic energy during deceleration. In this work, Computational Fluid Dynamics (CFD) simulations have been carried out using the Analysis of Variance (ANOVA) technique to determine the effects of design parameters on flywheel windage losses and heat transfer characteristics.

What is a flywheel energy storage system?

Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support the ro-tor/flywheel.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Can flywheel energy storage improve transport decarbonisation?

The critical contribution of this work is studying the relationships and effects of various parameters on the performance of flywheel energy storage, which can pave the way for the implementation of energy-efficient flywheel energy storage systems for transport decarbonisation.

Industry Information

- Tbilisi energy storage power import

- China China solar powered generator supplier

- Egypt Photovoltaic Panel Solar Manufacturer

- Niamey Uninterruptible Power Supply

- Majuro High Temperature Solar System

- Wind power lithium battery energy storage photovoltaic

- ASEAN Energy Storage Battery Distributors

- Island battery energy storage cabinet manufacturer

- Huawei Photovoltaic Energy Storage Space

- Are micro inverters fast-moving consumer goods

- Energy-saving new energy storage application

- Zambia imported energy storage battery models

- Battery energy storage makes money

- Battery safety of communication base stations

- How much does an industrial energy storage cabinet cost in Ghana

- Iraq Smart Energy Storage Cabinet Specification Company

- Estonian energy storage mobile power manufacturer

- Huawei s top ten cylindrical lithium batteries

- Lithium battery station cabinet control system principle

- Network communication base station wind power construction costs

- Sg225hx inverter rated voltage

- Electromagnetic battery for 5g communication base station

- Solar charging in Cordoba Argentina 36V 2W

Commercial & Industrial Solar Storage Market Growth

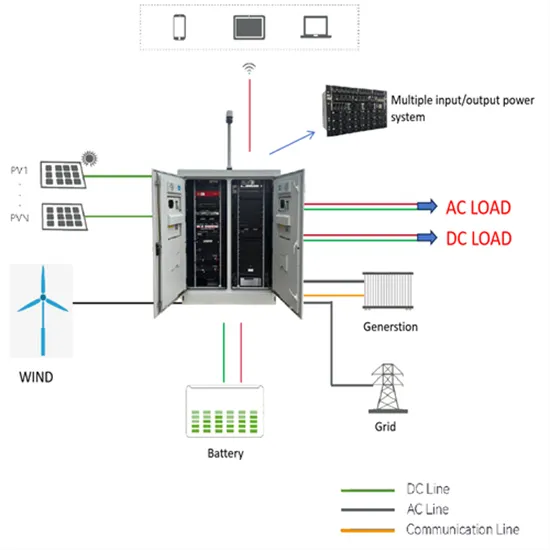

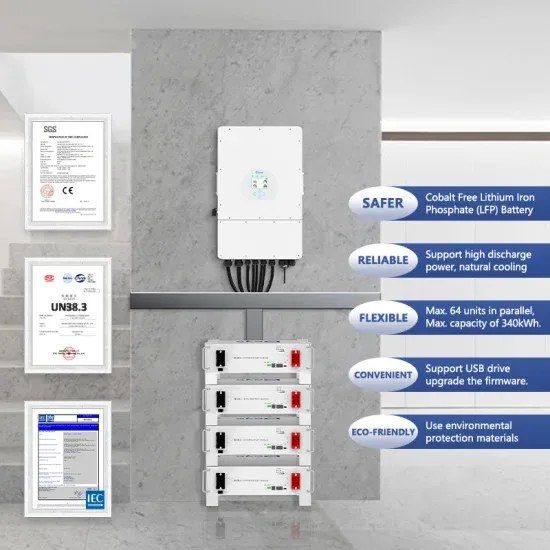

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.