Overview of Preparation Process of Lithium Iron

Jul 16, 2024 · This paper introduces the preparation mechanism, battery structure and material selection, production process and performance test of lithium

Lithium manganese iron phosphate (LiMn1

Jun 9, 2025 · The growing demand for high-energy storage, rapid power delivery, and excellent safety in contemporary Li-ion rechargeable batteries (LIBs) has

Recycling of lithium iron phosphate batteries: Status,

Jul 1, 2022 · The recycling of retired power batteries, a core energy supply component of electric vehicles (EVs), is necessary for developing a sustainable EV industry. Here, we

Preparation of Lithium Manganese Iron Phosphate Cathode

Among various methods for preparing LiMn 1-x Fe x PO 4, the high-temperature solid-state method has been widely used because of its simple process, low cost and high yield.

Production process of lithium iron phosphate

Jul 11, 2024 · The production process of lithium iron phosphate batteries is generally divided into several processes such as preparation, crushing, mixing, pressing, baking, physical and

LITHIUM MANGANESE IRON PHOSPHATE (LMFP)

Sep 19, 2023 · nese iron phosphate (LMFP), a type of lithium-ion battery whose cathode is made based on LFP by replacing some of the iron with manganese. LMFP batteries are attracting

Industrial preparation method of lithium iron

From the above production process comparison, we already know that the solid phase method is simple, and the liquid phase method is more complicated

Full-automatic production process of lithium iron phosphate

The invention discloses a full-automatic production process of lithium iron phosphate and the devices thereof, and belongs to the production technology field of positive materials of lithium

Environmental footprint assessment of China''s lithium iron phosphate

Jun 24, 2025 · Purpose With the rising demand for lithium iron phosphate batteries (LFPB), it is crucial to assess the environmental impacts of their production, specifically in the

Iron Phosphate: A Key Material of the Lithium

Oct 25, 2023 · Beyond the current LFP chemistry, adding manganese to the lithium iron phosphate cathode has improved battery energy density to nearly

Progress on lithium manganese iron phosphate cathode

Feb 15, 2025 · Lithium-ion batteries (LIBs) have been widely studied in academic circles and have achieved mass industrial production due to their high energy density, safety and stability, wide

Methods of synthesis and performance improvement of lithium iron

Mar 1, 2016 · Lithium ion battery technology has the potential to meet the requirements of high energy density and high power density applications. A continuous search for novel materials is

Advancements in Lithium Manganese Iron Phosphate as a

Jul 4, 2025 · Lithium manganese iron phosphate (LiMn 1–x Fe x PO 4, LMFP) is a promising cathode material for lithium-ion batteries, exhibiting high theoretical energy density, excellent

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

Description of Iron Phosphate Production Process

Aug 23, 2023 · This represents one further benefit. As the cost of phosphorus accounts for more than 53% of the production cost of iron phosphate, leading enterprises of integrated

Lithium Manganese Iron Phosphate (LMFP)

The doping of manganese in lithium manganese iron phosphate increases the operating voltage of battery cells, yielding greater energy density (210-240

LITHIUM MANGANESE IRON PHOSPHATE (LMFP)

Sep 19, 2023 · SUMMARY LMFP battery is a type of lithium-ion battery that is made based on lithium iron phosphate (LFP) battery by replacing some of the iron used as the cathode

What are the advantages and disadvantages of Lithium manganese iron

Aug 18, 2022 · Lithium iron phosphate is an electrode material for lithium ion batteries, it''s chemical formula is LiFePO4 (LFP for short), mainly used in a variety of Lithium ion batteries.

LiFePO4 VS. Li-ion VS. Li-Po Battery Complete

Mar 18, 2024 · Overview of Lithium Iron Phosphate, Lithium Ion and Lithium Polymer Batteries Among the many battery options on the market today, three

Progress of lithium manganese iron phosphate in blended

Jun 1, 2025 · Olivine-structured phosphate materials, such as LFP and LMFP, feature a three-dimensional phosphate framework structure, offering high thermal and cycling stability. Since

Lithium Manganese Iron Phosphate

Sep 11, 2022 · Abbreviated as LMFP, Lithium Manganese Iron Phosphate brings a lot of the advantages of LFP and improves on the energy density.

LFP Battery Production: Innovations

Jun 19, 2025 · Discover how one-pot synthesis and metal-to-cathode processes revolutionize lithium iron phosphate battery production with superior efficiency.

What is Lithium manganese iron phosphate

Aug 5, 2023 · Lithium manganese iron phosphate (LiMnxFe1-xPO4) is a new type of phosphate-based lithium-ion battery cathode material formed by doping a

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Progress on lithium manganese iron phosphate cathode

Feb 15, 2025 · The basic principle is to mix the main raw materials of lithium-ion battery cathode materials according to the proportion, including sources of Li, Mn, Fe and C, and then to carry

Lithium manganese iron phosphate materials: Design,

With the boom in electric vehicles (EVs), there is an increasing demand for high-performance lithium-ion batteries. Lithium manganese iron phosphate (LMFP) has emerged as an

What is Lithium Manganese Iron Phosphate Battery LMFP?

Feb 10, 2025 · Discover the benefits of Lithium Manganese Iron Phosphate (LMFP) batteries. Learn about their efficiency, safety, and applications in this comprehensive guide.

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · New pathways can also emphasize the fast-changing battery technology and the invention of different chemistries or various battery systems, such as LFP and lithium iron

Modification technology for synthesis process of lithium manganese iron

In response to the low conductivity of lithium manganese iron phosphate, the current main method of improving its conductivity is through modification. The mainstream modification methods

The origin of fast‐charging lithium iron

Jan 10, 2022 · The origin of the observed high-rate performance in nanosized LiFePO 4 is the absence of phase separation during battery operation at high

Past and Present of LiFePO4: From Fundamental Research to

Jan 10, 2019 · In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The

Next-gen LMFP batteries could boost EV range

Oct 12, 2024 · UK-based battery technology company Integrals Power has unveiled the next-generation Lithium Manganese Iron Phosphate (LMFP)

Modification Strategies for Enhancing the

Apr 7, 2025 · Graphical Abstract This review focuses on the structure and performance of lithium manganese iron phosphate (LMFP), a potential

Lithium Iron Phosphate and Lithium Iron Manganese

Jun 16, 2025 · However, the low intrinsic electron conductivity and rela-tively low lithium ion diffusion rate caused by the crystal structure characteristics of lithium iron phosphate batteries

Perspective on cycling stability of lithium-iron manganese phosphate

Nov 4, 2022 · Lithium-iron manganese phosphates (LiFexMn1−xPO4, 0.1 < x < 0.9) have the merits of high safety and high working voltage. However, they also face the challenges of

The Eve of Mass Production of Lithium Iron Manganese Phosphate Batteries

The mass production process of lithium iron manganese phosphate batteries has once again attracted the attention of the industry. Recently, Musk said that Tesla has been exploring the

Lithium Iron Phosphate (LFP)

Oct 5, 2023 · Starting materials for LFP synthesis vary but are comprised of an iron source, lithium hydroxide or carbonate (an organic reducing agent), and a phosphate component. The

Modification Strategies for Enhancing the

Apr 7, 2025 · In recent years, lithium manganese iron phosphate (LiMn x Fe 1–x PO 4, LMFP) has attracted considerable interest, primarily because of its high

6 FAQs about [Manganese phosphate lithium iron phosphate battery station cabinet production process]

Is lithium manganese iron phosphate a potential cathode material for next-generation lithium-ion batteries?

This review focuses on the structure and performance of lithium manganese iron phosphate (LMFP), a potential cathode material for the next-generation lithium-ion batteries (LIBs). How modifications like exotic element doping, surface coating, and material nanostructuring enhance its electrochemical properties are studied.

What is lithium manganese iron phosphate?

Lithium manganese iron phosphate (LiMn 1–x Fe x PO 4, LMFP) is a promising cathode material for lithium-ion batteries, exhibiting high theoretical energy density, excellent low-temperature performance, long cycle life, safety, and low cost.

What is lithium manganese iron phosphate (limn1 xfexpo4)?

This article has not yet been cited by other publications. Lithium manganese iron phosphate (LiMn1–xFexPO4, LMFP) is a promising cathode material for lithium-ion batteries, exhibiting high theoretical energy density, excellent low-temperature performance, ...

What is lithium manganese iron phosphate (LFP)?

Nat. Commun. 15, 4086. <p>With the boom in electric vehicles (EVs), there is an increasing demand for high-performance lithium-ion batteries. Lithium manganese iron phosphate (LMFP) has emerged as an enhanced variation of LiFePO<sub>4</sub> (LFP), offering an energy density 10%–20% greater than that of LFP.

What is Nese iron phosphate (Lmfp) battery?

nese iron phosphate (LMFP), a type of lithium-ion battery whose cathode is made based on LFP by replacing some of the iron with manganese. LMFP batteries are attracting attention as a promising successor to LFP batteries becaus

Can lithium phosphate be synthesized with a high manganese content?

The LiMn 0.79 Fe 0.2 Mg 0.01 PO 4 /C composites with high manganese content were successfully synthesized using a direct hydrothermal method, with lithium phosphate of different particle sizes as precursors .

Industry Information

- Double-glass module market demand

- Outdoor power supply 3 batteries

- Which company is the best for energy storage power supply

- What you need to assemble an outdoor power supply

- 12v inverter water pump

- Slovenia energy storage charging pile

- Abu Dhabi photovoltaic folding container manufacturer wholesale

- Communication energy storage and power energy storage

- Solar light big watt

- Energy storage cabinet is industrial battery

- Photovoltaic panel manufacturers direct sales

- Factory price 1000kw inverter in Ghana

- Romanian new energy storage manufacturer

- Connector size of small photovoltaic energy storage cabinet

- Usb c power station for sale in Cairo

- Serbia 10kw inverter brand

- Luxembourg Photovoltaic Curtain Wall R

- Tunisia inverter 6kw single phase

- Industrial Energy Storage Power Station Project

- High-performance hybrid solid-state energy storage battery

- Cyprus High Frequency Uninterruptible Power Supply Plant

- 2000w solar inverter for sale in Brisbane

- Huawei Tirana Battery Energy Storage Project

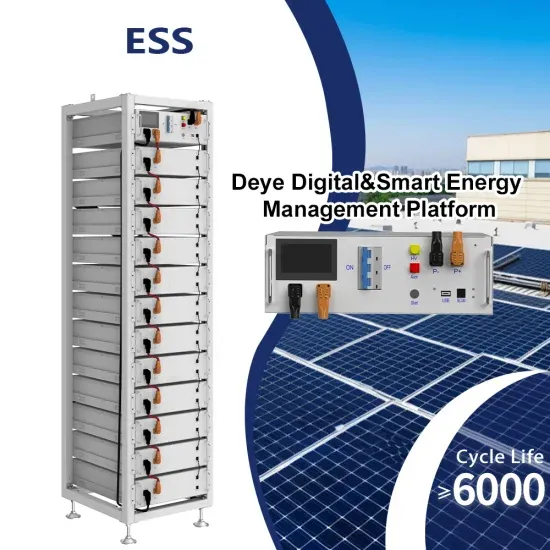

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.