4 Types of Industrial Cooling Systems

Apr 7, 2022 · Industrial cooling systems are essential in running major plants and industrial sites. Here are several types of these cooling systems that you may

Water treatment and cooling applications for power plants

Feb 12, 2019 · Water treatment and cooling applications for power plants Ninety-percent of electricity generated in the U.S comes from thermoelectric plants that are powered by coal,

Effect of Different Cooling Methods on LCC Calculation of Generator

Apr 1, 2024 · Download Citation | Effect of Different Cooling Methods on LCC Calculation of Generator-motors | The pumped storage power station has a promising future and attention

Power Generation/Steam Power

Jun 22, 2023 · This is the more preffered Cooling method which is now being implemented in most new Steam power stations. Steam is circulated inside a radiator-like heat exchanger and

Effect of Different Cooling Methods on LCC Calculation of Generator

The pumped storage power station has a promising future and attention should be paid to maximize its economic benefits. Life cycle theory is an advanced method used to measure

Cooling considerations

Mar 29, 2017 · Our engineering group, Aggreko Process Services (APS) and the nuclear station''s outage project team worked together to develop and install a temporary cooling system

Cooling Methods of Transformer

The AN, ONAN, ONAF, and OFAF cooling methods of the transformer are very important for transformer cooling. The cooling of the transformer brings the

How it Works: Water for Power Plant Cooling

Jun 5, 2024 · Conclusion Sustainable water management in power plant cooling systems is essential for reducing environmental impact and ensuring

High-Performance Generator Cooling Systems: Advanced

A generator cooling system is a sophisticated engineering solution designed to maintain optimal operating temperatures in power generation equipment. This critical system employs multiple

Generator cooling systems | Sterling TT

Power generation is a crucial in many industrial sectors. Keeping electrical generators cool improves their performance and longevity. Sterling TT designs

Advanced Generator Cooling Systems: Efficient

Nov 23, 2023 · Advanced generator cooling systems, including heat exchangers and intercoolers, have emerged as game-changers in hydropower plants.

Water Cooling System Form of Diesel Generator

The power station cooling system includes the diesel generator cooling system and the cooling system in the generator room. The selection of the cooling

The Methods of Cooling The Engine Room of

Jul 27, 2022 · In winter or excessive seasons, the power station should make full use of the cold air outside the project for ventilation and cooling. Therefore, air

Comparing Generator Cooling Systems: Air

5 days ago · Comparing Generator Cooling Systems: Air-Cooled vs. Liquid-Cooled When considering a generator for your home, one crucial aspect to

Effect of Different Cooling Methods on LCC Calculation of

J-STAGEThe pumped storage power station has a promising future and attention should be paid to maximize its economic benefits. Life cycle theory is an advanced method used to measure

What are the Different Generator Cooling System in Power

Oct 22, 2020 · The generator in the power plant are designed for continuous operation. Thus, the cooling system plays an important role in order to keep it''s reliability. Generators used in

Cooling of Compressor Air Inlet of a Gas Turbine Power

Sep 25, 2019 · Dayyabu Gambo Kofar-Bai and Qun Zheng, studied the effect of evaporative cooling of gas turbine power plant of some particular stations in Nigeria. Their results show

Different Generator Cooling Methods & Causes

Jul 27, 2021 · Different Generator Cooling Methods and their Advantages and Disadvantages to solve the overheating issue in machine generators.

Advanced Generator Cooling Systems: Efficient

Nov 23, 2023 · By utilizing advanced cooling systems, generators can operate at lower temperatures, reducing wear and tear on components and extending

Generator Cooling Systems

2 days ago · Each generator set manufacturer offers different cooling system design options. The two most common types are closed-loop and open-loop

Power Plant Cooling Systems: An Essential Guide

Nov 21, 2024 · Cooling systems in power plants dissipate the heat generated during electricity production, preventing equipment from overheating. They

Comparing Generator Cooling Systems: Air

5 days ago · Generators come with either air-cooling or liquid-cooling systems, each with distinct advantages and considerations. Air-cooled generators use

Cooling Methods of a Transformer

4 days ago · No transformer is truly an ''ideal transformer'' and hence each will incur some losses, most of which get converted into heat. If this heat is not

Generator Cooler: Which Cooling Method To

Here are some common methods for generator coolers: Method: Air cooling involves using fans and ventilation to dissipate heat from the generator. Air is

Types of Generators Used in Power Plants!

Sep 21, 2022 · Looking at the power plants and thinking how tough they work? Knowing the basics of a power plant won''t hurt, right? Check out the

Optimizing pre-cooling methods for liquid air energy

Jun 2, 2025 · Abstract. and Storage construction geographical of a LAES power intermittency corresponding station, the pre-cooling volatility lexibility, characterized of renewable

What are the different cooling methods used in synchronous

May 12, 2025 · Cooling in Large Synchronous Generators Large synchronous generators, particularly those used in power generation, require highly efficient cooling systems due to the

Steam Power Stations for Electricity and Heat Generation

Feb 17, 2023 · 4.1.1 Energy Conversion and System Components Power plants produce electricity, process heat or district heating, according to their task (Stultz and Kitto 1992).

What are the Two Ways That a Generator Can Be Cooled:

Apr 18, 2025 · When it comes to cooling a generator, one common method is air cooling. This technique uses air to keep the generator at a safe operating temperature. Understanding how

Generator Cooling | PDF

Feb 16, 2025 · The document discusses cooling methods for electric generators. Generators produce heat during operation from losses in the stator and rotor.

Optimizing Performance: The Critical Role of

Mechanism: Air cooling utilizes ambient air to dissipate heat directly from the generator. This process often involves using fans or blowers to force air over

Power Generation Systems

Various cooling methods are utilized, including air cooling, water cooling, and hydrogen cooling, each chosen according on the generator''s size, design, and

Chemistry Management in Generator Water Cooling during

Oct 8, 2019 · Description This document contains operating chemistry and layup guidance for cooling water for generators with water-cooled windings. This Technical Guidance Document

(PDF) A comprehensive scheme for cooling of

Mar 1, 2012 · The paper presents all-inclusive study of recent techniques between year 2008-2012 dedicated for the cooling of large size electric generators. A

COOLING TECHNIQUES AT ESKOM POWER STATIONS

Aug 24, 2021 · COOLING TECHNIQUES AT ESKOM POWER STATIONS COOLING TECHNIQUES AT ESKOM POWER STATIONS Three types of cooling systems are employed

Air cooled vs Liquid Cooled Generator

When run, electric generators produce a lot of heat. Air cooled vs liquid cooled? The electric generators need to be cooled from time to time to avoid damage

6 FAQs about [Power station generator cooling method]

What is a generator cooling system?

A generator cooling system is a sophisticated engineering solution designed to maintain optimal operating temperatures in power generation equipment. This critical system employs multiple cooling methods, including air cooling, liquid cooling, and hybrid approaches, to effectively dissipate heat produced during electricity generation.

How do I choose the right cooling system for my Generator?

To select the appropriate cooling system for your generator, consider factors such as power output, environmental conditions, available space, and maintenance requirements. Consulting with a reputable supplier or technician can help you determine which system best suits your needs.

Why is the cooling system important in a power plant?

The generator in the power plant are designed for continuous operation. Thus, the cooling system plays an important role in order to keep it's reliability. Generators used in power generation applications can be placed in three major design classifications based on the cooling medium used:

What are the different types of generator cooling systems?

The range includes: Air-cooled systems: These utilize air as the cooling medium and effectively dissipate heat from the generator components. Water-cooled systems: These employ water as the cooling medium and provide efficient heat transfer for optimum generator performance.

What are advanced generator cooling systems?

Advanced generator cooling systems use innovative technologies such as liquid or air cooling to regulate the temperature of generators. These systems ensure optimal performance and prevent overheating, enhancing the overall efficiency and lifespan of the generator. What are the benefits of using advanced generator cooling systems?

What are power plant cooling systems?

Cooling systems in power plants dissipate the heat generated during electricity production, preventing equipment from overheating. They play a pivotal role in maintaining operational efficiency, ensuring safety, and minimizing environmental impact.

Industry Information

- Main specifications of double-glass modules

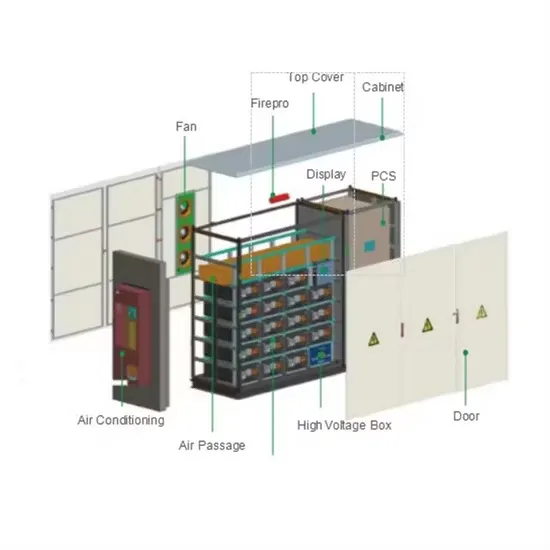

- Factory self-use energy storage power station

- What to do if the electricity bill for 5g base stations is expensive

- Old circuit breaker in China in Sao-Paulo

- China power breaker switch for sale producer

- Does flywheel energy storage generate electricity on its own

- Cube New Energy Storage Battery

- Battery Energy Storage in Serbia

- High quality 5kwh solar battery

- Flywheel Energy Storage in Cameroon

- Are cylindrical lithium battery cells the worst

- Is Macedonia s energy storage battery a lithium battery

- Kinshasa Photovoltaic Energy Storage Project

- Basic uses of Huawei energy storage power supply

- Tourism outdoor power supply 50 degrees

- Hybrid electrochemical energy storage

- Outdoor Multi-Tool Battery

- What brand of inverter should I use with lithium batteries

- Buy a small solar water pump

- How much is the wholesale price of photovoltaic folding container in Burundi

- Does the wind power station next door have batteries

- Managua Commercial Energy Storage Device Company

- Is it good to install solar panels on the roof of a container house

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.