Sodium-ion Batteries: The Future of Affordable Energy Storage

Jan 20, 2025 · These batteries facilitate a diversified supply chain, reducing dependency on specific countries for critical minerals important for green energy transition. The potential of

NGK''s NAS sodium sulfur grid-scale batteries in

Feb 6, 2017 · Japan-headquartered NGK Insulators is the manufacturer of the NAS sodium sulfur battery, used in grid-scale energy storage systems around

Sodium-sulfur battery energy storage container

A battery energy storage system For safety and security, the actual batteries are housed in their own structures, like warehouses or containers. During the next few decades, nickel

BASF, NGK Offer New NAS Battery With Novel

Jun 10, 2024 · BASF Stationary Energy Storage GmbH and NGK INSULATORS, LTD. have released an advanced container-type NAS battery (sodium-sulfur

Sodium Sulfur Battery

Sodium–sulfur batteries are rechargeable high temperature battery technologies that utilize metallic sodium and offer attractive solutions for many large scale electric utility energy storage

Sodium-Sulphur

Sodium sulfur (NaS) batteries are molten-salt batteries and consist of liquid sodium and liquid sulfur as active materials at the positive and negative electrodes, respectively. From: Energy

BASF, NGK release advanced type of sodium

Jun 10, 2024 · BASF Stationary Energy Storage, a wholly owned subsidiary of BASF, and NGK Insulators (NGK), a Japanese ceramics manufacturer, have

Sodium Sulfate: Future New Grid Energy-Storage

Aug 13, 2025 · Long-duration energy storage supports the need for high levels of variable renewable electricity by storing surplus energy and releasing it later.

Knowledge about battery energy storage

Jul 9, 2025 · The energy storage unit is the core component of the battery energy storage container, responsible for the storage and release of energy. Common

High and intermediate temperature

Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS). This review focuses solely

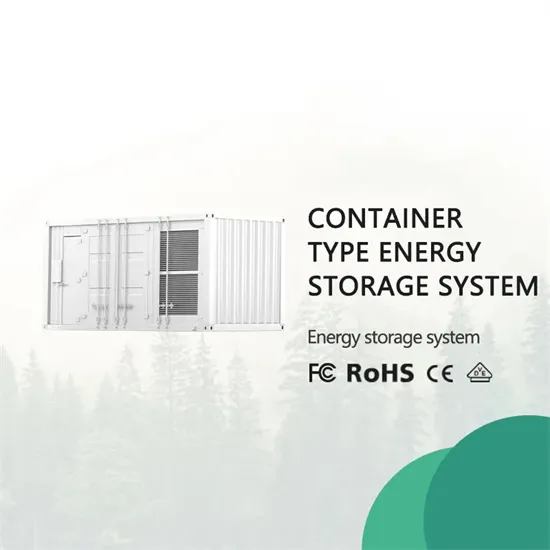

Energy storage container, BESS container

2 days ago · What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard

Why Sodium-Sulfur Battery Energy Storage Containers Are

May 8, 2022 · Who''s Reading This and Why Should They Care? renewable energy developers scratching their heads over how to store solar power for cloudy days. Grid operators sweating

NAS® Battery

NAS® Battery The NAS® battery, manufactured by NGK Insulators Ltd. in Japan and distributed globally by BASF Stationary Energy Storage GmbH, is made

Sodium-Sulfur (NAS )B

Mar 15, 2021 · Principle of Sodium Sulfur Battery Sodium Sulfur Battery is a high temperature battery which the operational temperature is 300-360 degree Celsius (572- 680 °F) Full

Shop | SHANGHAI ELECNOVA ENERGY STORAGE CO., LTD.

Energy Storage Battery Management System The energy storage BMS solution supports two modes: a three-level architecture (BMU sub-control module + BCU main control module +

Sodium-sulfur battery

A sodium-sulfur battery is a type of battery constructed from sodium (Na) and sulfur (S). This type of battery exhibits a high energy density, high efficiency of charge/discharge (89—92%), long

Jun 14, 2023 · Sodium-sulfur batteries have long offered high potentialfor grid-scale stationary energy storage,due to their low cost and high theoretical energy density of both sodium and

Na-S or Sodium-Sulfur Battery

Apr 21, 2008 · The Sodium-Sulfur battery is composed of a solid electrolyte membrane between its anode and cathode. Due to very high energy

Sodium-Sulfur (NaS) Battery

Jun 27, 2025 · A sodium-sulfur (NaS) battery is a high-capacity, high-temperature energy storage system that stores energy using molten sodium and sulfur as active materials. These batteries

A room-temperature sodium–sulfur battery with high

Sep 24, 2018 · High-temperature sodium–sulfur batteries operating at 300–350 °C have been commercially applied for large-scale energy storage and conversion. However, the safety

electrochemical energy Storage

May 25, 2020 · A. Physical principles A Sodium-Sulphur (NaS) battery system is an energy storage system based on electrochemical charge/discharge reactions that occur between a

Coal-dependent Mongolia''s first solar-plus

Mar 25, 2021 · The Asian Development Bank is also helping to progress a large-scale standalone battery energy storage system in Mongolia with 125MW

Construction of Mongolian BESS begins – Batteries

Oct 4, 2024 · The signing happened on September 6 by first deputy governor of Ulaanbaatar, Manduul Nyamandeleg and Zhibin Chen, a representative of Envision Energy for the

Coal-Dependent Mongolia''s First Solar-Plus

Mar 28, 2021 · The Asian Development Bank is also helping to progress a large-scale standalone battery energy storage system in Mongolia with 125MW

Sodium-Sulfur Batteries for Energy Storage

May 1, 2019 · This paper presents an overview of sodium-sulfur NAS battery used for battery energy storage system and custom power devices for power quality

NAS Batteries | Products | NGK INSULATORS, LTD.

The NAS battery is a megawatt-level energy storage system that uses sodium and sulfur. The NAS battery system boasts an array of superior features,

Sodium-Sulphur (NaS) Battery

May 25, 2020 · e order of 1 MW and 6-7 MWh. NGK has developed a new design, in which 6 modules of 33kW/200kWh are combi ed in one 20-foot container. The minimal commer-cial

kosovo sodium sulfur battery energy storage container sales

Next-generation sodium-sulfur battery storage: 20% lower cost, The battery is designed to provide bulk storage of electricity for medium- to long-duration energy storage (LDES) applications

Sodium Sulfur Battery – Zhang''s Research Group

Feb 25, 2015 · By Xiao Q. Chen (Original Publication: Feb. 25, 2015, Latest Edit: Mar. 23, 2015) Overview Sodium sulfur (NaS) batteries are a type of molten salt electrical energy storage

Australia pilots 1.5 MW sodium sulfur battery

Oct 4, 2024 · The charging step recovers metallic sodium and elemental sulfur. The battery runs at temperatures of around 300 C and both elements are in a

Introduction of Mongolia''s First Utility-Scale

Jun 30, 2023 · The First Utility-Scale Energy Storage Project aims to install a large-scale advanced battery energy storage system (BESS) in Mongolia''s

6 FAQs about [Ulaanbaatar sodium sulfur battery energy storage container]

Are sodium-sulfur batteries suitable for energy storage?

This paper presents a review of the state of technology of sodium-sulfur batteries suitable for application in energy storage requirements such as load leveling; emergency power supplies and uninterruptible power supply. The review focuses on the progress, prospects and challenges of sodium-sulfur batteries operating at high temperature (~ 300 °C).

What is a sodium sulphur battery system?

ec rochemical Energy Sto criptionPhysical principlessodium-sulphur (NaS) battery system is an energy storage system based on electrochemical charge/discharge reactions that occur between a positive electrode (cathode) that is typically made of molten sulphur (S) and a negative electrode (anode) that is typicall

What is a sodium-sulfur battery (NaS)?

Sodium also has high natural abundance and a respectable electrochemical reduction potential (−2.71 V vs. standard hydrogen electrode). Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS).

Can sodium and sulfur be used in electrochemical energy storage systems?

Overall, the combination of high voltage and relatively low mass promotes both sodium and sulfur to be employed as electroactive compounds in electrochemical energy storage systems for obtaining high specific energy, especially at intermediate and high temperatures (100–350 °C). 4.

Can sodium-sulfur batteries operate at high temperature?

The review focuses on the progress, prospects and challenges of sodium-sulfur batteries operating at high temperature (~ 300 °C). This paper also includes the recent development and progress of room temperature sodium-sulfur batteries. 1. Introduction

How does sulfur affect a high temperature Na-s battery?

Sulfur in high temperature Na-S batteries usually exhibits one discharge plateau with an incomplete reduction product of Na 2 S n (n ≥ 3), which reduces the specific capacity of sulfur (≤ 558 mAh g − 1) and the specific energy of battery.

Industry Information

- Which is the best liquid cooling energy storage in Abuja

- Does Sinosteel Power Supply have energy storage function

- What is a new energy battery cabinet

- Photovoltaic solar panels in rural Ljubljana

- Hungarian energy storage cabinet assembly

- Communication base station inverter grid connection approval document

- Iceland double glass photovoltaic curtain wall supplier

- M16r1 portable power bank

- How many companies are there in the field of communication base station inverters

- Energy Storage Container Environmental Assessment

- Micronesia Photovoltaic Home Energy Storage

- What is the purchase price of the battery in the energy storage cabinet

- 20 feet outdoor energy storage cabinet

- How much does a container energy storage cabinet cost

- Official battery replacement price for battery cabinet

- Spanish energy storage projects

- How long will it take for photovoltaic energy storage to be commercialized

- Paris Home System Energy Storage Battery

- Damascus RV Energy Storage Power Supply

- Which mobile outdoor power bank charges faster

- Inverter voltage halved

- Huawei Portugal factory energy storage project

- Which UPS is the cheapest in South Africa

Commercial & Industrial Solar Storage Market Growth

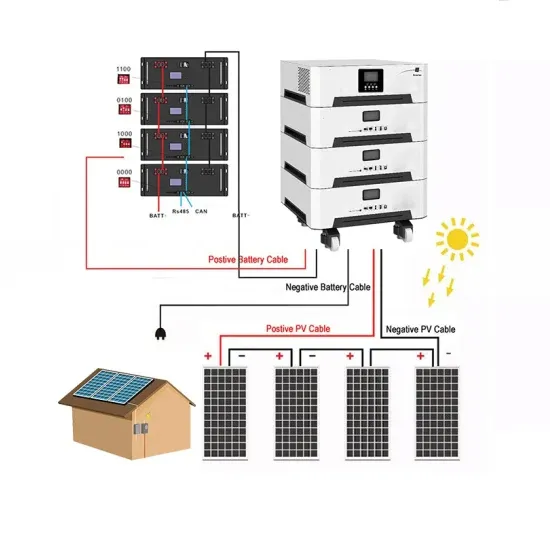

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.