The Future of Energy: Advancements in Battery Pack

Here are some key innovations driving the industry forward: 1. High-Density Lithium-Ion Batteries. Lithium-ion technology has become the gold standard for battery packs, thanks to its high

Tesla''s Shanghai Megafactory Begins Megapack

Feb 11, 2025 · Tesla (NASDAQ: TSLA) has officially started production at its Shanghai battery megafactory, dedicated to manufacturing its high-capacity

Hungary – the future paradise for EV battery

Jun 28, 2024 · A sslight overview about the EV battery producer companies which already operate manufacturing plants in Hungary or announced.

Inside an Energy Storage Battery Pack Factory: How

Aug 6, 2023 · EV makers are factory''s best customers, but here''s the twist – modern lines can switch between: Tesla''s Shanghai Megafactory reportedly churns out enough battery packs

Tesla Wet Process Iron LFP Battery Factory for

Jun 30, 2025 · Tesla has completed an Iron LFP battery factory in Nevada. This is probably going to take 1-2 years to hit volume production and the rumor is that

The battery industry has entered a new phase – Analysis

Mar 5, 2025 · In 2024, as electric car sales rose by 25% to 17 million, annual battery demand surpassed 1 terawatt-hour (TWh) – a historic milestone. At the same time, the average price of

Top Five: EV Battery factories in Europe

Apr 21, 2020 · The firm also has a joint venture to build a battery factory in Salzgitter, Germany. Called Northvolt Zwei, production is due to begin in 2021,

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · China has become the heartbeat of the global battery industry, reshaping how energy storage solutions are developed and deployed. As a

The sustainable factory of the future

Aug 14, 2023 · Learn how the evolution of manufacturing processes and technology provides the opportunity to think differently about sustainable factory operations.

Challenges and opportunities for high-quality battery

Jan 12, 2025 · The rise in battery production faces challenges from manufacturing complexity and sensitivity, causing safety and reliability issues. This Perspective discusses the challenges and

Challenges and opportunities for high-quality battery

Jan 12, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

battery factory | Electrek

Jul 9, 2024 · VW has announced another big battery investment, this time committing €20 billion to battery production through 2030 with a new battery

ONE''s 752-mile EV battery propels plans for its

Mar 7, 2022 · To put ONE''s ambitions into perspective, the Tesla Model S has an EPA-rated range of 405 miles (651 km), using a battery pack with a capacity

Future Factory

Leveraging future technologies. Revolutionising the manufacturing industry. Leveraging future technologies like Advanced Analytics and AI. The Future

Understanding gigafactories: EV Battery

Aug 19, 2025 · Learn about gigafactories, their roles in EV battery production, and the opportunities and challenges they present in the global energy transition.

The Battery Cell Factory of the Future

Feb 1, 2025 · The Battery Cell Factory of the Future – BCG Global demand for batteries is rising, but not as fast as market experts anticipated. As a result,

Building better electric batteries for battery

Apr 22, 2021 · Globally, the demand for BEVs is strong, prompting fierce competition among many companies for cost and technology leadership. If

Tesla Gigafactories: Pioneering the Future of

Sep 3, 2024 · Gigafactory 1, located in Sparks, Nevada, was Tesla''s first battery and vehicle production plant. It was inaugurated in 2016 and has become the

Factory of the Future

Factory of the Future Smart and sustainable. Digital and dynamic. These traits describe factories of the future—and the people who lead them. Reach your

Inside an Energy Storage Battery Pack Factory: How

Aug 6, 2023 · Rumor has it, one factory''s AI once ordered pizza for the maintenance crew before a scheduled shutdown. Okay, we made that up – but it''s 2025, who knows?

A Global Tour of Upcoming Battery Production

May 25, 2023 · 5/ Dyson''s New Battery Factory to Open in Singapore Dyson is not a car maker and will not provide the EV market with batteries. However,

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · As a leader in innovation, Chinese battery pack assemblers are transforming industries ranging from electric vehicles to renewable energy

Tata confirms Somerset will host £4bn battery

Feb 28, 2024 · The future site of the UK''s biggest electric vehicle battery manufacturing facility has been confirmed. Jaguar Land Rover-owner Tata

How Panasonic''s Battery Factory is Enhancing Procurement

Jul 28, 2025 · Panasonic''s new battery factory in Kansas marks a key development in procurement for the electric vehicle sector, targeting 32GWh capacity Panasonic has officially

American Battery Factory

Jul 18, 2024 · But American Battery Factory is working to establish itself as the foundation of an entire industry, and that means bringing the companies it

Inside a Modern Battery Factory: How Cutting

Sep 28, 2024 · Modern battery factories are at the forefront of this revolution, employing cutting-edge technologies to enhance production efficiency,

Geely builds its own battery factory, is it a money-saving

6 days ago · Geely has built a 5G smart factory in Quzhou, which can track battery production data throughout the process. The battery yield rate of the Jianhu base in Jiangsu is almost the

21 Advantages and Disadvantages of Factory Farming

Factory farming is a process that rears livestock with methods that are generally intensive. Most facilities will raise cattle, pigs and swine, or poultry indoors using this method under conditions

Smart Factory whitepaper

Smart factory benefits include uptime improvements, better asset utilization, data-driven factory optimization, and energy eficiency. Eficiencies can be achieved by reducing errors,

UK gigafactories: an explainer on

Jan 17, 2023 · Estimates suggest China has more than 100 operational gigafactories compared with just six in mainland

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

EV Battery Factory Map for North America

1 day ago · The total figure is broken down into individual EV battery factory projects—started in 2023 or future—listed by states in the map below. This

2025 Battery Roadmaps

Jan 20, 2025 · Perhaps closer to describe this as a start of 2025 review of the latest battery roadmaps, research and funding directions that will shape the

Having the Largest Electric Battery Factory in Southeast Asia

Jul 3, 2024 · This factory is the first and largest battery cell factory in Southeast Asia. With the development of an integrated electric vehicle ecosystem worth IDR 160 trillion, President

Tracking the EV battery factory construction

Feb 8, 2025 · Northvolt''s battery factory, located in Salzgitter, Germany, is set to become one of the largest in Europe. The project, which has received a

Factory of the future

Nov 14, 2022 · The ultimate goal of the factory of the future is to interconnect every step of the manufacturing process. Factories are organizing an unprecedented technical integration of

6 FAQs about [Which one has a better future battery factory or pack factory]

How can a battery factory become a competitive market?

Optimizing cell factories for next-generation technologies and strategically positioning them in an increasingly competitive market is key to long-term success. Battery cell production capacity globally could exceed demand by as much as twofold over the next five years, making operational efficiency essential to competitiveness.

How will the factory of the future improve battery production?

This reduces reliance on dedicated maintenance teams and prevents deterioration of equipment by maintaining it in optimal condition. We estimate that the factory of the future will reduce conversion costs in battery cell production by 20% to 30% from the 2024 baseline. (See Exhibit 5.)

Will the factory of the future reduce conversion costs in battery cell production?

We estimate that the factory of the future will reduce conversion costs in battery cell production by 20% to 30% from the 2024 baseline. (See Exhibit 5.) Cost savings can be achieved across the entire production process, with the most significant impacts on electrode production.

What is the battery cell factory of the future?

The battery cell factory of the future addresses the challenges of cost optimization through improvements in four dimensions. (See Exhibit 3.) Each dimension encompasses a variety of innovative measures, spanning different levels of technological maturity. (See “Technology Maturity Levels.”) Research Phase.

What makes a battery factory a good battery factory?

One underappreciated attribute of manufacturing performance is dynamicism, or the ability to respond to change. In an overly idealized view, a battery factory statically maintains fixed operational objectives.

How can battery cell producers improve cost efficiency?

By adopting this approach, battery cell producers can improve cost efficiency by up to 30% compared with the current industry average. As price pressure builds amid overcapacity, this is a pivotal moment for decision makers to define their vision for the factory of the future.

Industry Information

- Swiss inverter repair manufacturer

- Phase change energy storage system production

- Nigeria communication base station lithium ion battery cabinet price

- Middle East Uninterruptible Power Supply Customized Manufacturer

- Fully automatic solar light for home use

- Terrace loft solar power generation system

- Germany Hamburg commercial energy storage products company

- Grounding of distributed energy storage cabinet

- Does the company have energy storage products

- Energy storage container lithium battery module processing process

- Air energy storage investment cost

- Energy storage cabinet base station in the computer room

- How many watts does a 60 volt inverter carry

- Bangladesh rooftop photovoltaic energy storage

- Kinshasa rooftop solar power generation system

- What is a special energy storage container

- Moscow custom-made mobile energy storage power supply

- Micronesia Rural Outdoor Power

- Xiaomi energy storage cabinet battery new product price

- Solar Photovoltaic Panel Services

- How much is the electricity cost of a communication base station per year

- Factory price outdoor breaker in Cairo

- Bangladesh battery storage box manufacturer

Commercial & Industrial Solar Storage Market Growth

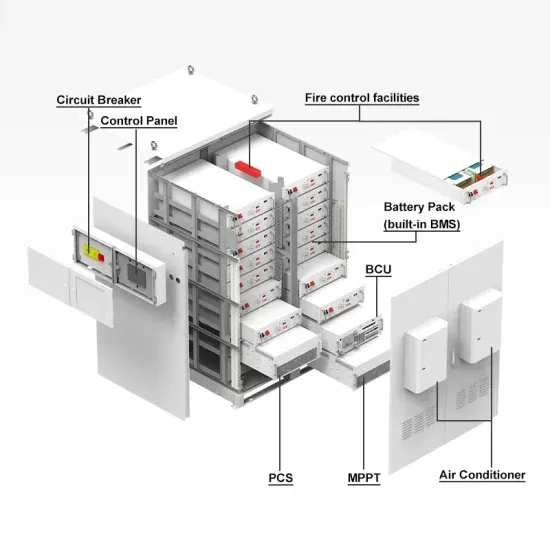

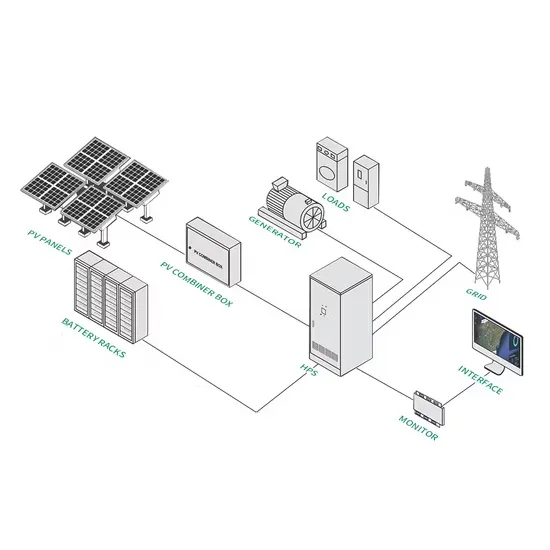

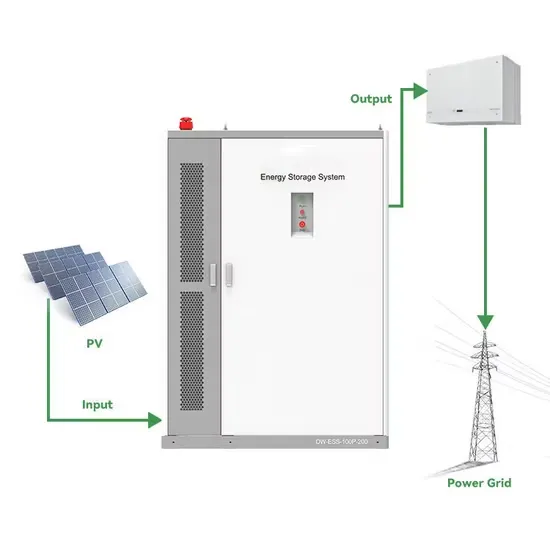

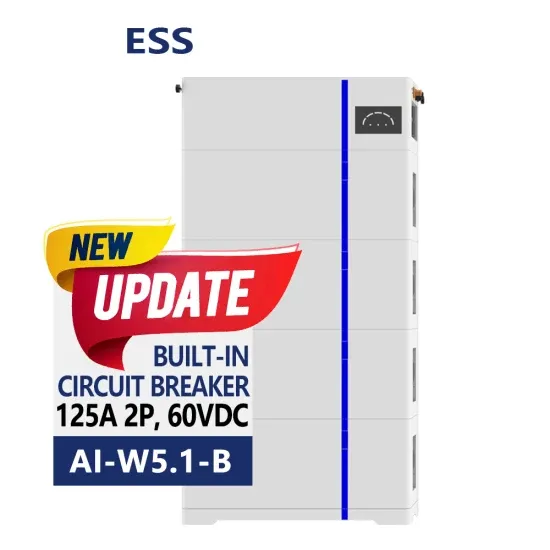

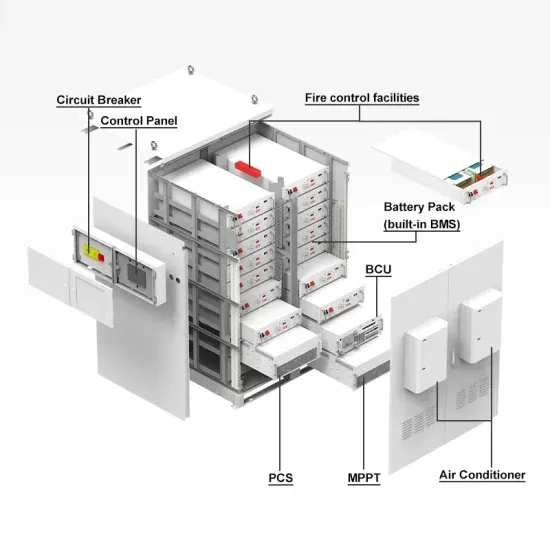

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.