(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

EVE官网请使用新网址访问

Full-scene thermal simulation and verification; Using EVE''s safe and reliable LFP batteries; Cell/module thermal isolation, improve system safety; System-level

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment

Energy Storage System

6 days ago · CATL''s energy storage systems provide energy storage and output management in power generation. The electrochemical technology and renewable energy power generation

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

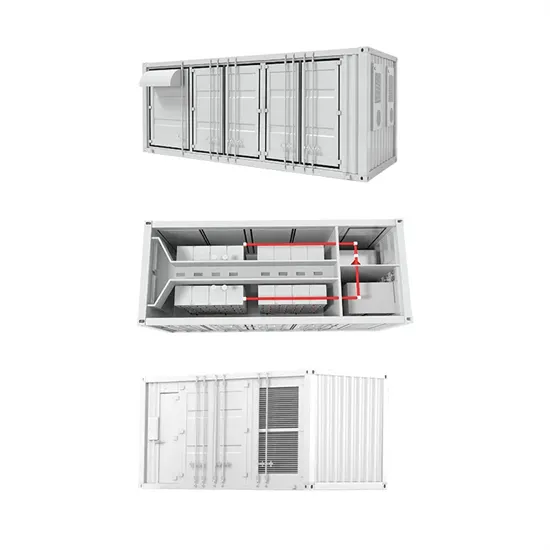

Energy storage container

Feb 28, 2023 · Energy storage container is an integrated energy storage system developed for the needs of the mobile energy storage market. It integrates

LFP Battery Manufacturing Process: Components

May 16, 2024 · Overview of LFP Battery Components and Materials Lithium iron phosphate (LFP) batteries, a kind of lithium-ion battery, have obtained

Explosion-venting overpressure structures and hazards of lithium

Oct 1, 2024 · Abstract With the rapid development of the electrochemical energy storage industry, energy storage system containers are widely used as a new facility for loading and

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Battery energy storage system components

A well-designed BMS is a vital battery energy storage system component and ensures the safety and longevity of the battery in any lithium BESS. The below

Battery cell, Battery Module or Pack. What''s the

Jun 20, 2023 · The manufacturing process is relatively simple, making it suitable for large-scale production. Large prismatic batteries, with individual battery

Manufacturing Process of Lithium-ion Batteries for Home Energy Storage

1 day ago · Home energy storage batteries are produced through a carefully controlled multi-stage process involving electrode preparation, cell assembly, and final processing. The technology

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

CATL EnerC+ 306 4MWH Battery Energy Storage

Jul 3, 2025 · The EnerC+ container is a modular integrated product with rechargeable lithium-ion batteries. It offers high energy density, long service

Battery Pack Assembly Process Series 7

Jun 6, 2025 · Installation process: Generally, the liquid cooling machine and the main liquid cooling pipe are installed first, and then the second and third level pipelines are installed. After

Energy storage container, BESS container

2 days ago · What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Manufacturing process The global demand for Li-ion batteries (LIBs) has been increasing rapidly because of the popularity of electric vehicles (EVs) and energy storage. The

Essentials of Container Battery Storage: Key

Dec 11, 2023 · At its core, a container energy storage system integrates high-capacity batteries, often lithium-ion, into a container. These batteries store

Review article Review on influence factors and prevention

Nov 20, 2023 · Energy storage technology is an effective measure to consume and save new energy generation, and can solve the problem of energy mismatch and imbalance in time and

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · In this section, we aim to peel back the layers of this intricate manufacturing process, shedding light on what makes lithium-ion batteries a backbone of modern energy

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · "Production process of lithium-ion battery cells", this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

Container energy storage battery manufacturing process

A Lithium Battery Storage Container securely houses lithium-ion batteries for efficient energy storage, essential for renewable energy integration, backup power, and grid

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Mar 10, 2024 · This data sheet also describes location recommendations for portable (temporary) lithium-ion battery energy storage systems (LIB-ESS). Energy storage systems can be located

CATL EnerC 0.5P Energy Storage Container

Jul 3, 2025 · EnerC liquid-cooled energy storage battery containerized energy storage system is an integrated high energy density system, which is in

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · In order to deliver the required power and energy as per the application, it is necessary to assemble the individual Li-ion cells in series and parallel configuration to make

Advanced Insights into Battery Energy Storage

May 22, 2024 · Discover the advanced guide to Battery Energy Storage Systems (BESS). Learn about BESS components, functions, and benefits, including

PRODUCTION PROCESS OF BATTERY MODULES AND

43% 68% 91% 57% 32% 9% With their ability to efficiently store large amounts of energy temporarily and then make them available as needed, battery systems in the form of battery

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

6 FAQs about [Energy storage container lithium battery module processing process]

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Why should you choose a lithium-ion battery module & pack line?

The whole system has no leakage of electricity, water, liquid or gas, which ensures the safety and stability of the production process. The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure high quality and efficiency in production.

What is the production process for chisage ESS battery packs?

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly, pack testing, and packaging for storage. Now, following in the footsteps of Chisage ESS, our sales engineers are ready to take you on a virtual tour!

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

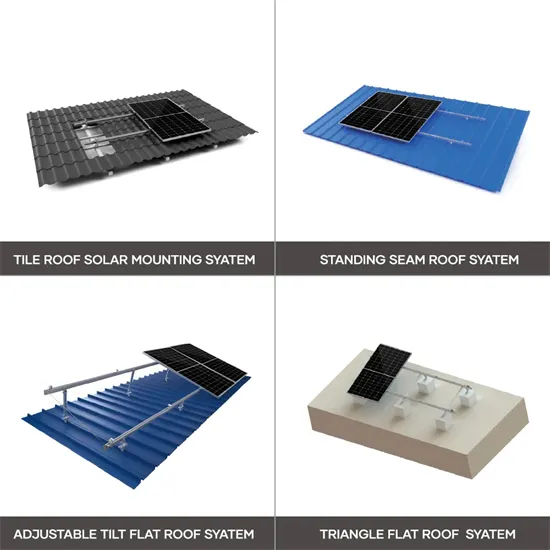

Industry Information

- North Korea s energy storage container industry and commerce

- Simple solar panel power generation system

- Mobile base station solar panels

- Photovoltaic module 545 monocrystalline double-sided

- Gaborone Photovoltaic Panel System Manufacturer

- How many types of photovoltaic energy storage systems are there

- Niue battery cabinet manufacturer

- Is there any site energy battery cabinet in Berlin

- Battery inverter model

- What is the minimum volt of outdoor power supply

- Riyadh Energy Storage Photovoltaic Engineering Enterprise

- Bess battery storage in China in Brisbane

- Communication Green Base Station on the roof

- The role of sodium-ion battery energy storage cabinet

- Photovoltaic inverter wfi

- Which kind of outdoor power supply is better in Riga

- Energy storage emergency power cabinet industrial design

- Construction site 220 inverter

- Hot sale power breaker switch factory producer

- How many magnetic 5g communication base stations are there

- Huawei Indonesia Surabaya Capacitor Energy Storage Project

- North Korea supercapacitor module price

- Integrated communication base station battery energy storage system battery

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.