Essential Guide: How to Check Battery with Ohm Meter for

Feb 21, 2025 · What To Know Imagine a battery as a water tank with a pipe connecting it to a faucet. In a battery, a high internal resistance signifies a battery that is struggling to deliver its

How to test the internal current of the battery cabinet

The lithium battery capacity test is based on the full-charge voltage and the set termination voltage as the parameters, because the minimum discharge voltage of the lithium battery is

How to Conduct a Battery Test: A Step-by-Step Guide

This article will guide you through the necessary steps and tools involved in performing a battery test. By learning these techniques, you can effectively evaluate battery health and determine

How to Test Lithium Ion Battery with Multimeter

Jan 31, 2025 · Learn how to test a lithium-ion battery using a multimeter for voltage, current, and overall health in simple steps.

⊳ HOW TO: Testing the car battery

Once the terminals are connected to the battery, the first thing that will appear on the display is "Battery test". Press the right arrow key to select "System test ", "Language selection", "Test

Test Batteries Safely And Effectively With These Simple

Sep 10, 2024 · In this section, we''ll explore three common battery testing methods: using a multimeter, performing a load test, and conducting a capacity test. One of the simplest battery

[Guide] How to Check a Lithium Battery with a Multimeter

Nov 6, 2024 · Testing a lithium battery is easy! Use our clear steps with a multimeter to check its power level. Learn how to do it now and stay charged!

The three-phase UPS battery handbook

Apr 3, 2025 · The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically to avoid

What are the Steps in Battery Testing? A

May 6, 2025 · How to use a battery test chamber for battery testing? Battery test chambers mimic extreme environmental conditions, temperature, humidity,

480.9 Battery Locations.

2014 Code Language including the Errata: 480.9 Battery Locations. Battery locations shall conform to 480.9 (A), (B), and (C). (A) Ventilation. Provisions

How To Test A Battery Before Repair? – DIY Battery Restoration

Testing a battery before repair can save you time, effort, and money. By carefully inspecting, measuring voltage, performing a load test, and recharging if necessary, you can diagnose your

NFPA 72 Battery Testing | National Training Center

Prior editions of 72 had about three tests for the batteries, those being the charger test, discharge test, and load test. Well, in 2019, the number of tests has gone

What Are The Three Basic Battery Tests?

Dec 20, 2024 · What Are The Three Basic Battery Tests? A battery is a chemical mechanism designed to provide standby power to critical equipment. It is comprised of an array of cells

Battery cabinet for safely charging lithium-ion

By choosing Batteryguard battery cabinets, you''re opting for the safest solution. Our certified safes protect your business against battery fires, ensure a safe

Proper Battery Testing Steps & Procedure

May 22, 2023 · The steps in battery testing involve a visual inspection for physical damage, a voltage check to make sure the battery is within a normal operating

Battery Inspection Checklist

Oct 10, 2024 · This detailed Battery Inspection Checklist ensures battery performance and safety. This checklist, which includes both visual and

Top 10 Battery Test Equipment Brands: Comparison and

Feb 8, 2025 · Top 10 Battery Test Equipment Brands: Comparison and Selection Guide Like humans, everything in the electrical and electronics world needs a power supply to perform its

How To Test A Battery With A Multimeter? A Simple Guide

Jun 21, 2025 · We''ll explore different testing methods, interpret the results, and address common challenges, providing a complete understanding of battery testing for both beginners and

TELECOMMUNICATIONS· VRLA BATTERY

Jan 10, 2023 · This paper describes a step by step program of methods and procedures for maintaining the VRLA battery systems in the Local Exchange Carrier Central Office and

Battery & Power Supply Testing!

Testing was pretty easy here. Notice the switch installed in the cabinet next to the batteries. This is a common occurrence in large networked systems because it

How to Test the Health of Your Low Voltage Cabinet

Mar 13, 2024 · How to Test the Health of Your Low Voltage Cabinet Batteries Periodic tests to ensure battery health are highly recommended. Typically, batteries last from three to five

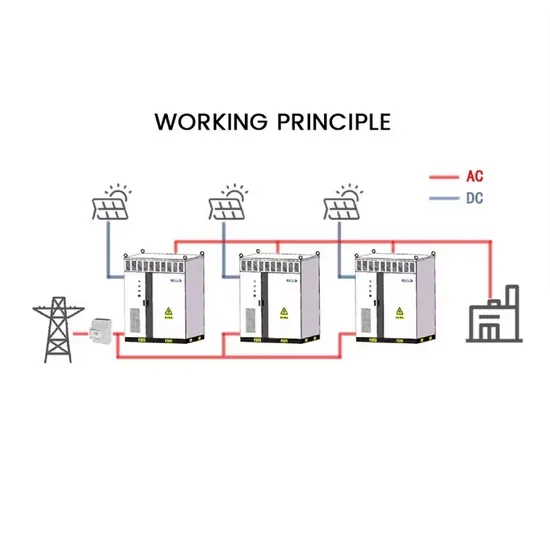

How to test the energy storage cabinet level

Performance testing is a critical component of safe and reliable deployment of energy storage systems on the electric power grid. Specific performance tests can be applied to individual

Lithium-Ion Batteries and Charging Fire Risk | The Safety Cabinet

A 90 minute fire rating has been achieved from an international testing facility for our lithium-ion battery charging cabinets. Max 1006 degrees C was achieved inside of the cabinet whilst the

Lithium battery safety explosion-proof cabinet test

A battery cabinet is a particular type of storage cabinet that reduces the risks associated with lithium-ion batteries. These innovative cabinets create a safer environment in which

ESS Battery Cell Performance Testing Cabinet

ESS Battery Cell Performance Testing Cabinet Brief Description The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical

BATTERY FIRE TEST: Storemasta 18-Outlet

Mar 31, 2025 · In summary, the 18-Outlet Battery Charging Cabinet successfully contained fire, projectile and heat hazards during this fire testing. Obvious

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept

How to Test a Car Battery: A Step-by-Step Guide

Apr 24, 2024 · Locate the battery – usually under the hood. Connect a battery tester by attaching leads correctly. Test voltage; good is around 13.8V.

Power Up: A Comprehensive Guide to Testing Your Battery''s

May 31, 2025 · What is battery health and why is it important? Battery health refers to the overall condition and performance of a battery, including its ability to hold a charge, retain capacity,

Battery Testing Procedure

Jan 10, 2025 · Discover the step-by-step battery testing procedure, including how to measure voltage, capacity, and internal resistance. Using this

Battery Test Chambers for Comprehensive

5 days ago · What Is a Battery Test Chamber? Battery test chambers simulate the most intense real-world conditions your cells are likely to encounter,

6 FAQs about [How to test the battery in the battery cabinet]

What are the steps in battery testing?

The steps in battery testing involve a visual inspection for physical damage, a voltage check to make sure the battery is within a normal operating range, a capacity test to compare current capacity to rated capacity, and an internal resistance test to assess the battery's overall health.

What is battery testing?

Battery testing comprises measuring the voltage, capacity, & other parameters of the battery with the help of a multimeter or another equipment. You will be able to tell whether a battery is defective, weak, or needs to be changed based on the results of the tests performed on the battery. What is the purpose of Battery Testing?

How do you test a car battery?

To confirm a car battery, start with preparation: maintain it well and clean terminals. Locate the battery – usually under the hood. Connect a battery tester by attaching leads correctly. Test voltage; good is around 13.8V. Perform a load test and check alternator too. Keep an eye on voltage while the car runs. Address any issues promptly.

How do you know if a battery has a rated capacity?

Capacity is measured in amp hours. If you test the capacity of your battery, you will be able to compare it to its rated capacity. A cell or battery is generally understood to be at the end of its life span when it is only able to store 80% of what it was originally able to.

How do you know if a battery is good?

Internal Resistance Test: This is the most telling performance figure for battery cells. Calculating internal resistance will indicate the health of the battery and how much current it can safely and practically supply.

How do you test a lithium battery?

Lithium batteries come in many shapes, so look for the "+" and "-" markings on the battery to determine its positive and negative terminals. Set the multimeter level to 20V on the DC setting. Turn the knob on the front of your multimeter to direct current (DC) and pick a maximum voltage level before taking a reading.

Industry Information

- High quality magnetic breaker in Cebu

- Solar photovoltaic water pump price in Thailand

- Micro base station outdoor power supply

- Huawei Belgrade Energy Storage Container

- Inverter practical power

- Huawei Maputo Portable Energy Storage Power Supply

- BIPV photovoltaic curtain wall in Gomel Belarus

- Guatemala s largest battery energy storage project

- New Energy Storage Power in the Middle East

- Borderless photovoltaic panel size specifications

- Current investment costs for energy storage

- Huawei Lithium Energy Storage Power Supply

- Lithium iron manganese phosphate energy storage battery

- Pretoria LiFePO4 battery connected to inverter

- Rwanda EK container energy storage price

- Serbia outdoor base station power cabinet company

- Build a communication base station supercapacitor at home

- Application of lithium battery industrial energy storage

- Huawei s easy-to-install photovoltaic curtain wall advantages

- Columbia High Temperature Solar System

- Berne Industrial Energy Storage Manufacturer

- Flywheel energy storage motor installation

- Solar battery storage factory in Canberra

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.