Flywheel Energy Storage

Flywheel energy storage technology uses reversible bidirectional motors (electric motor/generator) to facilitate the conversion between electrical energy and the

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Peer Review Oct 2005

May 15, 2012 · Objective: • build and deliver flywheel energy storage systems utilizing high temperature superconducting (HTS) bearings tailored for uninterruptible power systems and

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

(PDF) Design and Analysis of a Unique Energy

Apr 1, 2015 · This paper presents a unique concept design for a 1 kW-h inside-out integrated flywheel energy storage system. The flywheel operates at a

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Flywheel Energy Storage Systems | Electricity Storage Units

1 day ago · RotorVault''s flywheel cells can be containerized for simple and scalable deployments. Each module is housed within a durable, weather-resistant shipping container, allowing for

Design and Analysis of a Highly Reliable Permanent Magnet

Aug 13, 2024 · This article aims to propose a highly reliable permanent magnet synchronous machine (PMSM) for flywheel energy-storage systems. Flywheel energy-storage systems are

Energy Storage | Falcon Flywheels | England

Grid-Scale Kinetic Energy Storage Falcon Flywheels is an early-stage startup developing flywheel energy storage for electricity grids around the world. The rapid fluctuation of wind and solar

World''s largest flywheel energy storage

Sep 19, 2024 · A project in China, claimed as the largest flywheel energy storage system in the world, has been connected to the grid.

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · Flywheel Systems for Utility Scale Energy Storage is the final report for the Flywheel Energy Storage System project (contract number EPC-15-016) conducted by Amber Kinetics,

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate th

Flywheel Energy Storage for Automotive

Sep 25, 2015 · A review of flywheel energy storage technology was made, with a special focus on the progress in automotive applications. We found that there

Installation of flywheel energy storage motor

nergy storage: flywheel energy storage (FES). Introductio especially for large-scale applications. The main cost drivers are the materials, manufacturing, and installation of the

Control Method of High-power Flywheel Energy Storage

Feb 29, 2024 · The flywheel energy storage converts electrical energy into mechanical energy in the process of charging, while the discharge converts mechanical energy into electrical energy

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · More recently, flywheel systems were developed as true energy storage devices, which are also known as mechanical or electromechanical batteries. A remarkable example of

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

How much power does the flywheel energy

Apr 26, 2024 · Flywheel energy storage motors exemplify an exceptional advancement in power delivery solutions, merging high-efficiency mechanical

A Utility-Scale Flywheel Energy Storage System with a

Nov 13, 2017 · Energy storage is crucial for both smart grids and renewable energy sources such as wind or solar, which are intermittent in nature. Compared to electrochemical batteries,

Introduction to motors and controllers of flywheel energy storage

Abstract: This paper introduces flywheel energy storage system (FESS) with particular focus on motors and controllers. The paper covers the principle and characteristics of permanent

The Ultimate Guide to Flywheel Energy Storage Motor Installation

Oct 16, 2023 · Ever wondered how Formula 1 cars recover energy during braking? Meet their cousin: flywheel energy storage motors. As industries scramble to adopt sustainable energy

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

A review of flywheel energy storage systems:

Mar 8, 2021 · Thanks to the unique advantages such as long life cycles, high power density and quality, and minimal environmental impact, the

Flywheel energy storage motor installation diagram

What are the components of a flywheel energy storage system? A flywheel energy storage system consists of bearings,a rotating mass,a motor-generator,and a frequency inverter. Fig. 14.4

A Comprehensive Analysis of the Loss

May 28, 2025 · This paper presents a comprehensive analytical framework for investigating loss mechanisms and thermal behavior in high-speed magnetic

Regenerative drives and motors unlock the

Jul 14, 2022 · S4 Energy, a Netherlands-based energy storage specialist, is using ABB regenerative drives and process performance motors to power its

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Flywheel energy storage and motor installation

Installation location: The FESS compartment should be installed in an isolated area where minimal heat will exchange with the environment, especially in environments with high thermal

Industrial Solutions Flywheel UPS Systems, 50-1000 kVA

Dec 27, 2021 · Summary The flywheel, using technology, stores kinetic energy in the form of a rotating mass and is designed for hi power, short time discharge applications. The technology

6 FAQs about [Flywheel energy storage motor installation]

What is a flywheel energy storage system?

A typical flywheel energy storage system , which includes a flywheel/rotor, an electric machine, bearings, and power electronics. Fig. 3. The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

What is flywheel technology?

Flywheel technology is a method of energy storage that uses the principles of rotational kinetic energy. A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds.

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Industry Information

- Acceptance of base station power lines

- Best factory price serket breaker distributor

- Standard Energy Storage System Management

- Lithium battery intelligent storage control system dedicated to solar energy monitoring

- Flow Battery Benefits

- The difference between photovoltaic cells and energy storage

- Lima Energy Storage Industrial Park Project

- How many 5G base stations does Iraq have

- Mobile outdoor power supply for construction sites

- Energy storage power supply export container manufacturer

- Solar dedicated on-site energy panels

- Which photovoltaic inverter to choose

- How much does a San Diego container energy storage cabinet cost

- Circuit breaker fuse in China in Belgium

- Wholesale switchboard switchgear

- How much does a solar power system cost in Belarus

- What is an inverter cabinet

- Luxembourg lithium battery pack

- Accra outdoor communication battery cabinet replaced 6 9MWh of batteries

- Berlin generator container

- 4G base station outdoor unit installation

- Armenia communication base station energy storage cabinet in stock

- Minsk basic farmland solar photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

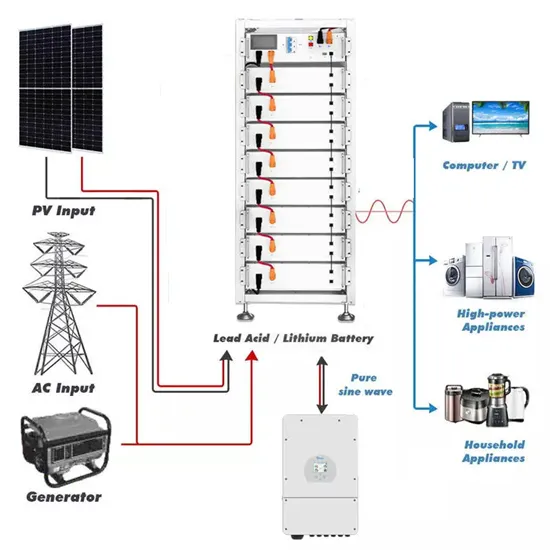

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.