Steel components for battery housings

Aug 13, 2020 · Targets can not be reached without electrification of the drive train! Why steel? » What have a high volume VW Golf 7 TSI Blue Motion 1.2 and a Carinthian Drautaler cheese in

Lightweight Design of an Automotive Battery

Sep 26, 2021 · The battery packs are crucial components of electric vehicles and may severely affect the continue voyage course and vehicle safety. Therefore,

Electric Vehicle Battery Packs

Jan 10, 2023 · SAFETY, FUNCTIONALITY & PERFORMANCE FOR ELECTRIC VEHICLE BATTERY PACKS With growing concerns of anthropogenic climate change and the imposition

Structural optimization of light-weight battery module based

Dec 1, 2020 · In this work, the advantages of a novel hybrid cooling for a battery module are demonstrated over the single liquid cooling and the encapsulant cases, and then a structural

Steel components for battery housings

Aug 13, 2020 · Performance Ultra light weight variant Steel cost efficient light weight construction Aluminum-bottom plate supports at impact of side crash Functional integration of cooling in

Prepare the Empty Battery Cabinet for Cables – Bottom

Drill or punch holes for power cables and signal cables in the gland plates. Reinstall the gland plates.

Major player consortium announces new lighter EV battery

Aug 7, 2024 · The structure of the housing was realised by Vestaro with a bottom plate made of aluminium. Transversal beams are used to attach the battery modules, and the carrier plate for

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

Thermal runaway behaviour and heat generation

Mar 1, 2024 · The findings of this study provide insights into the TR behaviour of a marine battery cabinet and its influence on heat generation as well as guidance for the thermal management

Slim Battery Cabinets

Apr 9, 2024 · Battery Cabinets are available as slim type, heavy duty type & rack mountable type for different installation requirements. Different standard

Battery Enclosures | Kautex

Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any of our customers'' EV needs, from

Support Systems For ALEXA 35 | Camera Support

The CBP-LW bridge plates are lightweight alternatives to the classic ALEXA 35 CBP. They operate on ARRI Bottom Plates as classic bridge plates and retain

Lightweight Lithium Battery Cabinet for Commercial Use and

Jul 15, 2025 · The company′s main products include: Lithium battery charging explosion-proof cabinets, Chemical safety cabinets, laboratory workbenches, fume hoods, vibration-proof

Battery cabinet

Apr 10, 2025 · 1. Cabinet size: 18U*600*800mm; 2. Structure: Top and bottom frame structure, front and rear door with door lock,left and right side panal

High-rigidity light-weight battery pack structure

The purpose of the utility model can be realized by the following technical scheme: a high-rigidity light-weight battery pack structure comprises a battery pack upper shell, a battery module, a

EV Battery & Housing Plate

6 days ago · Lightweight Design: Composite panels significantly reduce the weight of battery housing and cooling plates, contributing to increased EV

Bottom Plates | Farnell® UK

Buy Bottom Plates. Farnell® UK offers fast quotes, same day dispatch, fast delivery, wide inventory, datasheets & technical support.

Battery Cold Plate

Built with lightweight aluminum, the battery cold plate stabilizes battery cell temperature and provides optimal temperature uniformity. Featuring

Complete Guide for Battery Enclosure

May 29, 2024 · What is Battery Enclosure? A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the battery and all

Safe EV battery housings using high

An interesting option for battery housings is Forta H-Series, a new generation of fully-austenitic stainless steel developed for safety-critical structural vehicle

B2BCHINA is a major B2B site for Chinese suppliers, factories

B2BCHINA is a major B2B site for Chinese suppliers, factories, exporters, manufacturers. – Leg Warmers,Quilt Sets,Towable Backhoes,Standard Pencils,Electric Iron

Battery Cabinet

A maximum of three battery groups in up to six battery cabinets can be deployed inside the smart module. If many batteries are configured, they can be deployed outside the smart module. If

Analysis of Factors Influencing the Bottom Impact Safety

Oct 20, 2024 · This study employed simulation methods to analyze the impact of road obstacles on the traction battery system and investigated how impact energy influences its structural

A Structural Investigation of Bottom Plate Casing

Aug 30, 2024 · The bottom protection plate or the underfloor material of the traction battery pack is subjected to various operational stress, including protection from road debris, impact

A Structural Investigation of Bottom Plate Casing

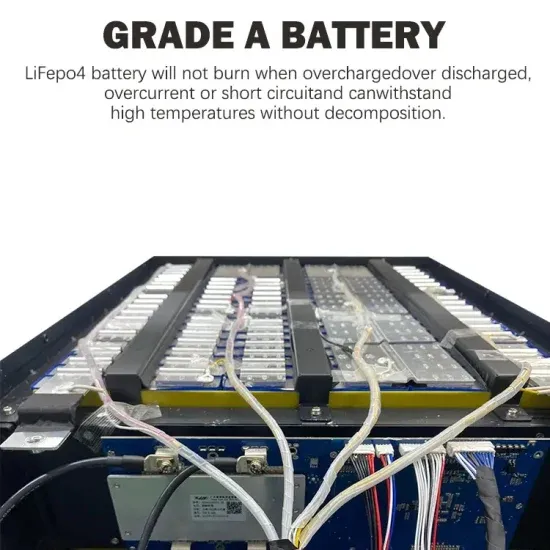

Aug 30, 2024 · The Battery & its structure The core of a BEV is its battery pack, typically utilizing lithium-ion cells due to their superior energy density, extended cycle life, and lightweight

Slim Battery Cabinets

Apr 9, 2024 · MODIK Battery Cabinets are available in different types for different applications. Battery Cabinets are available as slim type, heavy duty type &

MODIK

Apr 9, 2024 · MODIK Distribution Board consists of cabin, door with quarter turn lock and PU seamless gasket, front plates, removable cable gland plates on

ELECTRIC VEHICLE BATTERY PACKS

Depending on material and design requirements, SABIC''s Specialties business can provide a number of materials for electric vehicle battery packs, including

Battle for the EV Battery Box

Mar 17, 2023 · Potential applications include battery-pack bottom plates where impact resistance is key. However, the new alloy requires special

Cabinet Solutions

It seamlessly abuts your existing cabinets and its compact design is less than 12 inches wide. Its lightweight aluminum construction is ideal for rooftop

Aluminum Battery Enclosure Design

Feb 11, 2021 · As battery costs and energy density continue to improve, the $-value of light–weighting will be reduced, and we expect to see increased material competition. The

Vacuum Brazed Liquid Cooled Plates for Electric

Vacuum Brazed Liquid Cooled Plates for Electric Utility Truck Battery Pack Bottom Cooling A cold plate is responsible for taking the heat from the

Lightweight Lithium Battery Cabinet for Commercial Use and

Jul 15, 2025 · Lightweight Lithium Battery Cabinet for Commercial Use and off-Grid Power Solutions, Find Details and Price about Battery Cabinet Cabinet Battery from Lightweight

Justrite Lithium Ion Battery Storage Charging

Jul 23, 2024 · The lightweight, benchtop design makes it easy to move the cabinet wherever you need it. Lockable doors keep your lithium-ion batteries

Research on Battery Box Lightweight Based on

PDF | On Jan 1, 2017, Qiu-Sheng Chen and others published Research on Battery Box Lightweight Based on Material Replacement | Find, read and cite

6 FAQs about [Lightweight battery cabinet bottom plate]

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

What is a lithium-ion battery charging cabinet?

The Justrite Lithium-Ion Battery Charging Cabinet is the ultimate solution for safely charging and storing your lithium-ion batteries. Each charging station locker has multiple layers of advanced shielding to help reduce the risk of battery fires and thermal runaway.

What is a battery cold plate?

Built with lightweight aluminum, the battery cold plate stabilizes battery cell temperature and provides optimal temperature uniformity. Featuring counterflow and double-side cell loading designs, it extracts heat from the lithium-ion battery cells and enables fast charging. Copyright © 2025 Dana Limited. All Rights Reserved

What is a Justrite battery storage cabinet?

Every Justrite battery storage cabinet is made from strong 18-gauge steel. It has double-walled sides, top, and bottom with a 1.5-inch air gap between the walls. The manual-close doors have baffled vents and a unique flame arrester pattern. They are supported by continuous piano hinges for a secure and reliable closure.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

Industry Information

- Nigeria container energy storage system

- Basseterre Battery Energy Storage Cabinet

- Building Solar Air Conditioning System

- Which manufacturer of photovoltaic panels is good in Ireland

- Sanaa Energy Storage Container Procurement Bidding

- Huawei Tirana Energy Storage Power Plant

- 6kw inverter for low voltage cabinet

- Estonia container size wholesale

- Lithium iron phosphate chemical energy storage power station

- Cadmium oxide thin film photovoltaic glass

- Estonian energy storage cabinet fire protection system manufacturer

- How much is the price of outdoor power supply in Maldives

- Energy Storage Connectivity Solutions

- Lithium titanate batteries are assembled into battery packs

- Lithium battery pack voltage conversion 220v

- Cheap high voltage breaker for sale exporter

- Supercapacitor Price in Manama

- Photovoltaic power inverter photovoltaic power supply

- Communication base station solar photovoltaic power plant

- Photovoltaic power storage extended warranty

- Grid-connected inverter grid power outage

- European UPS uninterruptible power supply manufacturers

- Lithium battery energy storage cycle number

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.