Cadmium Telluride Solar Cells on Ultrathin Glass for Space Applications

Mar 15, 2014 · This paper details the preliminary findings of a study to achieve a durable thin-film CdTe photovoltaic (PV) device structure on ultrathin space-qualified cover glass. An aluminum

CdTe photovoltaics boost efficiency by 13% with

Jun 9, 2025 · Cadmium telluride solar cells are the most widely used thin-film solar technology in the world, but their performance still has significant room

Photovoltaic performance of magnetron sputtered antimony selenide thin

Nov 1, 2023 · Thin Solid Films Volume 784, 1 November 2023, 140070 Photovoltaic performance of magnetron sputtered antimony selenide thin film solar cells buffered by cadmium sulfide and

Cadmium Telluride/Cadmium Sulfide Thin Films Solar

Nov 5, 2023 · Shen et al. reports the performance of CdTe thin-film solar under low light intensity, this results demonstrate that polycrystalline CdTe thin-film solar cell is intrinsically suitable for

Polycrystalline Thin-Film Research: Cadmium Telluride

Jun 2, 2025 · Cadmium telluride (CdTe) photovoltaic (PV) research has enabled costs to decline significantly, making this technology one of the most economical approaches to adding new

Optical Properties of Cadmium Oxide (CdO) Thin Films

Dec 28, 2023 · Abstract Cadmium (Cd) is a soft, silver-white or blue lustrous metal typically found in mineral deposits with lead, zinc and copper. Cadmium Oxide thin films have been prepared

NSG TEC™ for Solar Applications

Used in Thin Film Photovoltaics, NSG TEC™ is a range of coated glass designed and optimised for each of the main thin film photovoltaic technologies,

Cadmium tin oxide thin films deposited by RF magnetron

Apr 15, 2013 · Abstract Cadmium tin oxide (CTO) thin films were deposited by radio frequency (RF) magnetron sputtering from a CdO:SnO 2 target onto glass substrates at temperatures

Thin film cadmium telluride solar cells on ultra-thin glass in

The direct application of CdTe PV to space grade ultra-thin cover glass has the potential to meet emerging space-based applications requiring higher specific power, greater stability to

NSG TEC™ for Solar Applications

NSG TEC™ for Solar ApplicationsThe NSG TEC™ products have a range of haze and sheet resistances that enables them to meet the needs of most thin

Comparative study of cadmium telluride solar cell

Jul 23, 2024 · CdTe solar cells were fabricated using MOCVD, according to the superstrate structure on two different glass substrates: fluorine-doped tin oxide (FTO)-coated soda-lime

Characterization of CdO Thin Films Prepared By SILAR

Feb 14, 2015 · Abstract—Cadmium oxide thin films were deposited by Successive Ionic Layer Adsorption and Reaction (SILAR) method using as a source material of cadmium acetate and

Brief review of cadmium telluride

Jun 27, 2014 · Cadmium telluride (CdTe) is the most commercially successful thin-film photovoltaic technology. Development of CdTe as a solar cell

Structural and transport properties of spray pyrolysed Ce:

Mar 17, 2025 · In the present study, spray pyrolysis was used to deposit undoped and cerium (Ce) doped cadmium oxide (CdO) thin films with doping concentrations (3, 5 and 7 wt %) films on

Optical Properties of Cadmium Oxide (CdO) Thin

Feb 1, 2017 · Cadmium (Cd) is a soft, silver-white or blue lustrous metal typically found in mineral deposits with lead, zinc and copper. Cadmium Oxide thin

Cadmium-manganese oxide composite thin films: Synthesis

Jan 15, 2017 · The surface topography of the cadmium-manganese oxide composite thin films fabricated on FTO-coated glass substrates was investigated by field-emission gun scanning

Cadmium Telluride

Aug 17, 2025 · DOE supports innovative research focused on overcoming the current technological and commercial barriers for cadmium telluride (CdTe)

Al-Diffused ZnO Transparent Conducting Oxide Thin Films for Cadmium

Oct 28, 2022 · Fluorine-doped tin oxide (FTO) or tin-doped indium oxide (ITO) thin films are widely used and commercialized as the transparent conducting oxide window layer in conventional

A novel recycling approach: separation and analysis of TCO-coated glass

Apr 3, 2025 · The ubiquitous adoption of photovoltaic (PV) modules as a renewable energy source for electricity generation has led to significant increase in their deployment. Among thin

Chapter 1.19: Cadmium Telluride Photovoltaic

Dec 31, 2012 · The chapter reviews the history, development, and present processes used to fabricate thin-film, CdTe-based photovoltaic (PV) devices. It

What Are CIGS Thin-Film Solar Panels? When to

Mar 6, 2022 · Thin-film solar panels are among the most advanced and efficient power generation technologies created for the solar industry. These

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Apr 3, 2025 · Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

What Are CdTe Solar Panels? How Do They

Dec 11, 2024 · Find out the composition of Cadmium Telluride CdTe solar panels, how they compare to other thin-film panels and crystalline silicon panels!

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · Rigid thin-film cells have other commercial applications (inserting or interleaving between two panes of glass) in some of the largest photovoltaic power stations in the world.

A comprehensive review of flexible cadmium telluride solar

Nov 1, 2023 · However, despite this advancement, certain issues regarding metal and p-CdTe remained unresolved. Besides, the fabrication of a full-working device on flexible glass is

Synthesis and Properties of Cadmium Oxide Thin Films

Jan 1, 2019 · In this paper, CdO thin films have been fabricated by the simple chemical method. The structural, morphological and optical been studied. XRD measurement disclosed that the

A new type of solar greenhouse covering

Aug 7, 2025 · Cadmium telluride thin-film solar cells are photovoltaic devices formed by sequentially depositing multiple layers of semiconductor thin films

Cadmium telluride (CdTe) thin film solar cells

Jan 1, 2022 · Semiconductors are the basic photovoltaic materials used in inorganic solar cells. Recently, research activities have shifted progressively toward thin film solar cells utilizing

CdTe-based thin film photovoltaics: Recent advances,

Jun 15, 2023 · Cadmium telluride (CdTe) thin-film PV modules are the primary thin film product on the global market, with more than 30 GW peak (GWp) generating capacity representing many

Research on ultra-thin cadmium telluride heterojunction thin film

Jan 1, 2025 · Cadmium Telluride thin film solar cell is very suitable for building integrated photovoltaics due to its high efficiency and excellent stability. To further reduce the production

Cadmium Telluride/Cadmium Sulfide Thin Films Solar

Nov 5, 2023 · 1.1 Cadmium telluride (CdTe) and 1.5 eV for single crystal form.[3] It shows excellent electrical and optical properties (Table. 1). Since it is used in various optoelectronics

Research on ultra-thin cadmium telluride heterojunction thin film

Download Citation | On Jan 1, 2025, Yunpu Tai and others published Research on ultra-thin cadmium telluride heterojunction thin film solar cells | Find, read and cite all the research you

Cadmium Telluride Solar Cell

Cadmium telluride (CdTe) solar cells contain thin-film layers of cadmium telluride materials as a semiconductor to convert absorbed sunlight and hence generate electricity. In these types of

6 FAQs about [Cadmium oxide thin film photovoltaic glass]

Why is CdTe thin film solar cell suitable for building integrated photovoltaics?

Cadmium Telluride thin film solar cell is very suitable for building integrated photovoltaics due to its high efficiency and excellent stability. To further reduce the production costs, relieve the scarcity of Tellurium, and apply in building integrated photovoltaics, ultra-thin CdTe photovoltaic technology has been developed.

What is thin film photovoltaic (PV)?

Introduction Thin film photovoltaic (PV) technologies often utilize monolithic integration to combine cells into modules. This is an approach whereby thin, electronically-active layers are deposited onto inexpensive substrates (e.g. glass) and then interconnected cells are formed by subsequent back contact processes and scribing.

What are the advantages of cadmium telluride (CdTe) thin film solar cells?

1. Introduction Cadmium Telluride (CdTe) thin film solar cells have many advantages, including a low-temperature coefficient (−0.25 %/°C), excellent performance under weak light conditions, high absorption coefficient (10 5 cm⁻ 1), and stability in high-temperature environments.

What materials are used in CdTe thin film solar cells?

The main materials used in CdTe thin film solar cell modules include transparent conductive oxide glass (TCO), high-purity CdTe, conductive pastes, and back electrodes. Among them, except for transparent conductive oxide glass, CdTe raw materials account for the highest cost .

When did CdTe thin film solar cells come out?

CdTe thin film solar cells first emerged in the 1970s, Bonnet and Rabenhorst introduced CdS/CdTe heterojunction in CdTe devices, and achieved an efficiency of 6 %. Since then, researchers began to use this type of heterojunction to prepare CdTe thin film solar cells.

Why is CDs thin film used in solar cells?

It is widely used as a buffer layer in solar cells because of its superior optoelectronic properties. The optical transparency of the film can be easily controlled by thickness variation. The optimized thickness of CdS thin film for solar cell applications is 120 nm. This cell achieved higher efficiency of 21%.

Industry Information

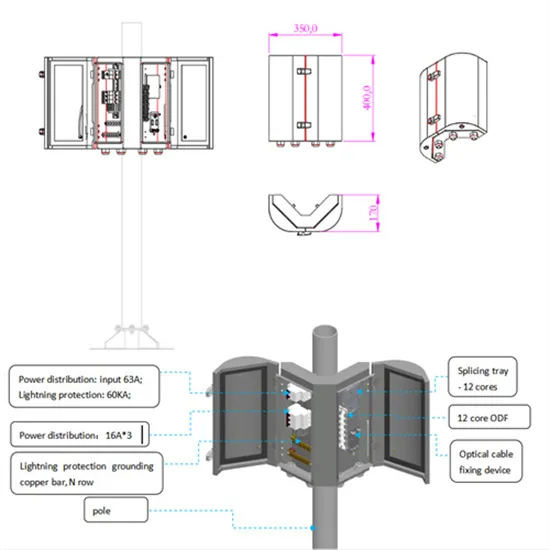

- Stockholm Free Outdoor Communication Power Supply BESS

- New Energy Battery Cabinet Storage Pool

- China-Africa Energy Storage Peak Shaving Price

- Can the outdoor power supply be increased in power

- High quality China bolt on circuit breaker for sale

- Yaounde new energy base station subsidies

- Flywheel energy storage plus disc generator

- Luxembourgonn outdoor power supply

- What to use for outdoor power fast charging

- Columbia Energy Storage Project

- Solar Energy Storage Direct Flexibility

- Ottawa photovoltaic glass manufacturer

- North Korea solar power generation and energy storage manufacturers

- Energy Storage Integrated Systems Company

- Can photovoltaic energy storage battery packs be connected in parallel

- How much does it cost to install a water pump with solar energy

- Photovoltaic power generation rural rooftop solar panels

- Solar power solutions factory in Sweden

- Wholesale 300wh power station in Norway

- Terrace home solar power generation system

- Finished distribution cabinet container base station

- Solar Panel On-site Energy Design Ideas

- Seoul three phase inverter sales

Commercial & Industrial Solar Storage Market Growth

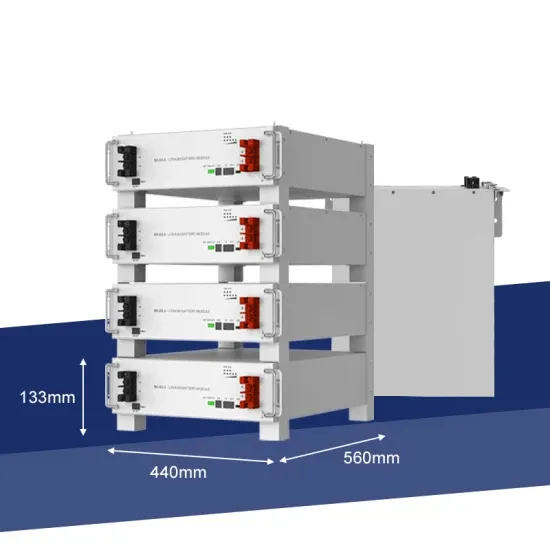

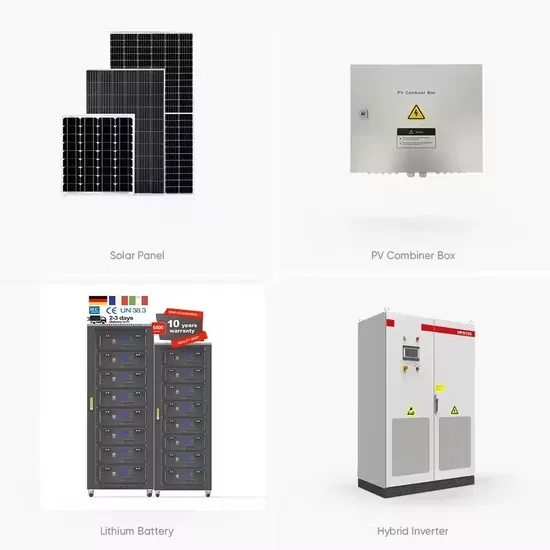

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.