Battery Packaging Architectures: Materials

Jan 7, 2025 · Challenges surrounding battery packaging architecture include dealing with packaging space, thermal management, and optimizing battery

Exploring the energy and environmental sustainability of

Jan 1, 2025 · The development of battery materials and pack structures is crucial for enhancing electric vehicle (EV) performance and adoption. This study examines the impact of Ni-rich

Requirements-oriented factory planning in the

Nov 16, 2023 · In order to reduce risks and simplify commissioning, Metroplan and the Fraunhofer Research Institution for Battery Cell Production FFB have

Battery Pack Manufacturing Process

Mar 15, 2025 · Assessing Client Requirements: Identifying power needs, form factor, and environmental conditions. Design & Prototyping: Creating CAD models and prototypes to

Battery Certification Requirements: Safety and

Jan 6, 2025 · Discover battery certification requirements, testing processes, and costs to ensure safety and compliance for lithium-ion batteries and other

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

Manufacturing

Control for quality ENVIRONMENT CONTROL The importance of environmental control is often underrated in battery pack manufacturing. The temperature

Electric Vehicles Batteries: Requirements and Challenges

Mar 18, 2020 · Introduction Since the commercialization of lithium-ion batteries (LIBs), tremendous progress has been made to increase energy density, reduce cost, and improve

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The Battery Production specialist department is the point of contact for all questions relating to battery machinery and plant engineering. It researches technology and market

What are battery pack maintenance requirements?

Learn essential battery pack maintenance requirements including daily inspections, temperature monitoring, BMS health checks, and safety protocols to maximize performance and lifespan.

Introduction to Power Battery Packs-JONVER

Apr 10, 2025 · Pure electric vehicles (EVs) use high-capacity batteries as their sole power source, typically lithium-based batteries. Lithium batteries are categorized into ternary and non-ternary

Understanding Battery Pack Technology: Key Components, Production

Mar 14, 2025 · Discover the essential aspects of battery pack technology, including key components such as cells, BMS, structural components, thermal management, production

Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

Electric Vehicles Batteries: Requirements and

Mar 18, 2020 · The market share of electric vehicles (EVs) increases rapidly in recent years. However, to compete with internal combustion engine vehicles,

From Raw Materials to Finished Product: The

Nov 10, 2024 · Introduction Lithium-ion batteries are the most used batteries worldwide. This is because they are known as an important technology for

Requirements-oriented factory planning in the

Nov 16, 2023 · The key messages from this development process are now being published in a joint white paper. The publication, entitled "Requirements

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Whether you''re targeting electric vehicles (EVs), energy storage systems (ESS), or consumer electronics, this guide outlines critical steps, budget considerations, and

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Raw Material Procurement and Inspection The lithium battery module PACK production line requires various materials such as battery cells,

Production & Testing Solutions Battery & EV Requirements

Mar 12, 2025 · Weiss Technik designs, develops and delivers high-quality battery production and battery test chambers solutions that ensure your power sources can power through harsh and

Automotive Battery Pack Standards and Design

Mar 18, 2025 · This review aims to bridge the gap between academic research and industry requirements by providing a structured analysis of automotive battery pack standards, key

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · In order to deliver the required power and energy as per the application, it is necessary to assemble the individual Li-ion cells in series and parallel configuration to make

Sustainable manufacturing practices for EV battery packs:

Jun 1, 2025 · As an end result, there is a growing want for sustainable production practices that lessen energy consumption, minimize environmental impact, and enhance the recyclability of

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

An overview of global power lithium-ion batteries and

Mar 5, 2022 · From the environmental assessment of a battery pack''s entire life stage (including battery production, operation, end of life and recycling of various materials), it can be seen that

Bridging the regulatory gap: A policy review of extended

Jun 1, 2025 · The production of electric vehicles in China is continuously increasing, leading to the issue of retired power batteries recycling. According to the degree of end-of-life (EOL), the

Production & Testing Solutions Battery & EV Requirements

Apr 11, 2025 · Weiss Technik designs, develops and delivers high-quality battery production and battery test chambers solutions that ensure your power sources can power through harsh and

ESS''s Battery Pack Design Checklist: Your

Apr 26, 2025 · What are the peak power and duration requirements? Will the pack face high vibration, salt spray or altitude extremes? How often will it charge?

Production requirements of lithium battery PACK

May 27, 2024 · Fully understand the usage requirements, such as application environment (temperature, humidity, vibration, etc.), usage time, charging and discharging methods and

Pack Sizing and Requirements

Jul 4, 2025 · In the first instance it is all about requirements. What are the hard points, the inviable parameters?

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Abstract The latest advancements and near-future trends in automotive battery packs, underlying regulatory compliance, and performance requirements are presented in this

PowerPoint Presentation

2 days ago · Power Differently ''FourHighsandTwoLow''sFramework LargePower''sengineeringphilosophyisbuiltonafoundationoftechnology-driveninnovationand

6 FAQs about [Power battery PACK production environment requirements]

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the parts of a battery production line?

Segments of the production line ● The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and safety requirements. ● From the point of view of factory layout, the assembly line can therefore be divided into cell-to-stack, stack-to-module and module-to-pack.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

Why do you need a customized battery pack?

Different industries require customized battery packs tailored to specific voltage, capacity, and form factor requirements. Customization ensures optimal performance, safety, and efficiency for various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems. 1.

What makes a good battery pack?

Whether you’re a professional or a curious reader, this guide will provide a clear and detailed overview. The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack.

What information does a battery pack contain?

Each shipment contains essential information: Complete Documentation Package: Performance test results, warranty information, user manuals, and installation guidelines accompany each battery pack, ensuring proper implementation and operation. The installation process follows systematic steps:

Industry Information

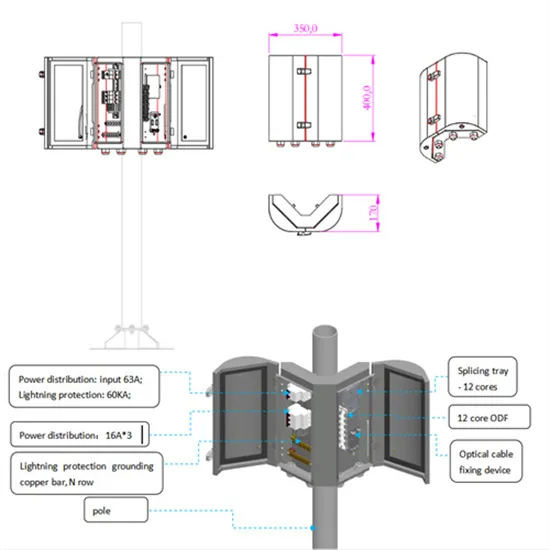

- Baghdad communication base station battery energy storage system equipment maintenance

- Lilongwe outdoor power lithium battery bms structure

- 40W Split Solar Light

- What is the role of lithium-ion batteries in rooftop communication base stations

- How much power does the outdoor power supply transmit

- Uninterruptible power supply distance between base station rooms

- Off grid solar power inverter in Norway

- Outdoor communication base station emergency power supply

- Battery cabinet installation production line base station

- Photovoltaic power station inverter conversion efficiency

- Cyprus energy storage product manufacturer

- Sao Tome and Principe Institute of Chemical Physics Energy Storage Battery

- Huawei Fiji outdoor power brand

- How much does it cost to import a high voltage inverter

- Industrial mobile power box wholesale price

- West Asia 200 000 installed capacity energy storage power station

- Are large-capacity energy storage batteries reliable

- How much watts does the integrated solar light have

- Lithium battery packs directly connected in parallel

- Supercapacitor manufacturer in Kampala

- Photovoltaic solar panel equipment processing manufacturer

- Does the grid-connected construction of communication base station inverters require planning

- Luanda service energy storage battery merchants

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.