Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage

Outdoor Cabinets

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which

The BESS System: Construction, Commissioning,

3 days ago · Check the battery cabinet placement against the construction drawing. Ensure there is maintenance space and a distance of more than 0.5

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Installation and hardware | Base Help Center

System specifications and installation procedureHow do I connect my battery to my home WiFi network? This article will help you connect your battery to your WiFi. It will also help you

SmartRescue Base Stations (2500 Series)

3 days ago · A code-compliant two-way communication system for rescue assistance requires a central control point to manage emergency assistance

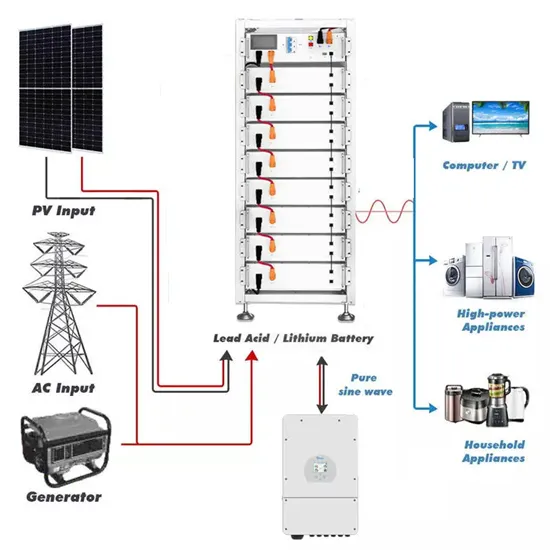

The role of photovoltaic battery cabinet installation line

The variability of photovoltaic (PV) power constitutes the overarching barrier preventing large-scale solar grid integration, with supply-demand imbalances exacerbated during extreme

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

VRLA battery cabinets

3 days ago · Total protection during downtime - Designed to satisfy and respect safety protection standards. - The right size of protection device tailored to your power rating. - Robust cabinet.

What are the base station energy storage

May 28, 2024 · Base station energy storage cabinets are critical components of telecommunications infrastructure designed to ensure reliable power supply,

Solar Battery Cabinet Equipment Enclosures for on-grid or

Climate controlled products such as air conditioners,heat exchanger, or TEC coolers are installed on outdoor battery cabinet for keeping a stable temperature inside cabinet so as to increase

Battery Manufacturing Basics from CATL''s Cell

Jun 14, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Düperthal BATTERY station line M safety cabinet

This safety cabinet is an innovative storage and charging system for lithium-ion rechargeable batteries / lithium-ion batteries. Düperthal developed this

Battery cabinet assembly principle of battery cabinet

-48 VDC Battery Cabinet . Installation and User Manual . Specification Number: 554631 . Model Number: 211. BC. NOTE! Supplied with the battery cabinet is a yellow alarm lead assembly

Assembly line for battery modules and battery packs

3 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

What is an energy storage battery cabinet?

May 22, 2024 · As the demand for sophisticated battery cabinets grows, it catalyzes job creation in research, production, and installation sectors. This

LISTA

LISTA electrical cabinets are perfect for the safe, personal storage of battery-powered devices of all kinds. These robust all-rounders are idea for offices

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

Equipment layout and clearances

Aug 28, 2007 · In line-ups where battery back-up cabinets may be needed, the footprint location must be ascertained ahead of time because batteries cannot

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

BATTERY station M

The BATTERY line safety storage cabinets are specially designed for safe storage and charging of lithium-ion batteries. With its Type 90 classification

Battery Storage Cabinet

KDST provides high-performance battery energy storage cabinet solutions, specially designed for key applications such as telecom base stations, industrial control, and power systems.The

P2962/D53 Jan 2025

Feb 13, 2025 · This document provides recommended practices for system design, storage, installation, ventilation, instrumentation, operation, maintenance, capacity testing, a

BATTERY station XL

The BATTERY line safety storage cabinets are specially designed for safe storage and charging of lithium-ion batteries. With its Type 90 classification

asecos: ION-LINE safety storage cabinets

Safety storage cabinets for passive or active storage of lithium-ion batteries according to EN 14470-1 and EN 1363-1 with a fire resistance of 90 minutes

Power Base Stations Battery Cabinets | HuiJue Group E-Site

As 5G deployment accelerates globally, power base stations battery cabinets face unprecedented challenges. Did you know 68% of network downtime originates from backup power failures?

BATTERY station connect XL

The BATTERY line safety storage cabinets are specially designed for safe storage and charging of lithium-ion batteries. With its Type 90 classification and explosive burning of batteries in the

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

6 FAQs about [Battery cabinet installation production line base station]

Where should battery back-up cabinets be installed?

In line-ups where battery back-up cabinets may be needed, the footprint location must be ascertained ahead of time because batteries cannot be added easily to side-by-side cabinets when battery back-up cabinets are in the center of a line-up. The battery cabinet must be installed adjacent to the power cabinet.

How to install a battery cabinet?

Check the battery cabinet placement against the construction drawing. Ensure there is maintenance space and a distance of more than 0.5 meters from heat sources. Follow the battery installation diagram and manual for installation. Wipe dust off battery terminals and check that each bolt is tightened before installing connection bars.

What are the minimum clearance requirements for a base station?

Minimum clearances must be maintained between the cabinets and surrounding building parts/cabinet to accommodate the installation and maintenance of the base station. The following constraints must be considered for cabinet clearances:

What are the steps in energy storage installation?

The main steps are: to build the foundation, install the energy storage cabinets, install the battery and inverter, and wire it all. During the commissioning of an energy storage system, which tests does the team perform? System-wide joint commissioning.

How to install a battery?

Batteries are pre-charged before leaving the factory. Wrap all metal installation tools with insulating tape to prevent short circuits. Maintain a gap between batteries during installation for good heat dissipation. Clarify the installation method and load-bearing conditions before starting. 2. Installation Steps

How to install a containerized energy storage system?

Use an insulating heat-shrinkable tube for secure terminal fit and label wires clearly. Clean up any foreign objects in the distribution cabinet. Connect all metal shells within the energy storage box to form a grounding network using good conductors or dedicated grounding strips. 6. Containerized Energy Storage System Installation Complete

Industry Information

- High quality new circuit breaker for sale Wholesaler

- Communication base station inverter grid connection and signal

- Standards for wind power size of communication base stations

- Notification of the completion of Nordic energy storage project

- Cheap blown circuit breaker factory producer

- How much does the Bridgetown power inverter cost

- Advantages and disadvantages of energy storage pcs system

- Brand high power portable power bank

- Praia power frequency isolation 250kw inverter

- Wholesale 1600 amp switchgear in Oman

- Container outdoor power supply 2000W

- Energy storage container push-pull structure

- Solar panels plus on-site energy

- Ulaanbaatar Solar Power System Installation

- Baghdad 40-foot energy storage container factory

- Mobile power box modification

- DC screen battery cabinet price in East Africa

- Nassau Industrial Energy Storage Manufacturer Supply

- UPS battery cabinet a32 size

- How much does a super battery cabinet cost

- Asmara Independent Energy Storage Power Station

- Lima PV grid-connected inverter

- Kuwait mining UPS uninterruptible power supply price

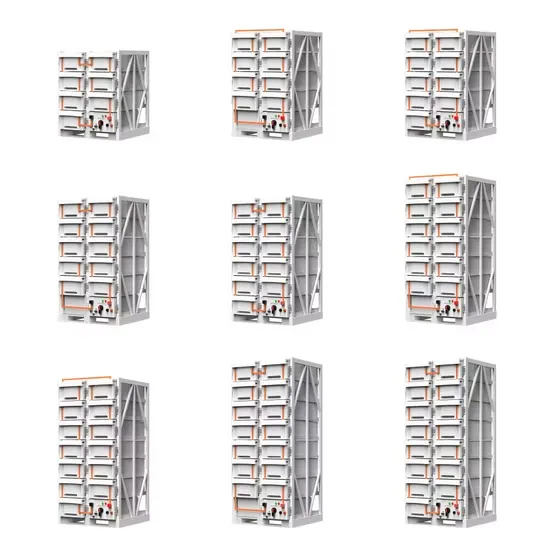

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.