Photovoltaics

SINGULUS TECHNOLOGIES provides production equipment (PVD, PECVD & Wet Processing) for photovoltaics: for both crystalline and thin-film high

Solar Cell Manufacturing: A Comprehensive Guide

Solar cell manufacturing is a critical process in the solar manufacturing sector, which has been growing rapidly in recent years. Solar cells are the building blocks of solar panels, which are

A Comprehensive Guide to Solar Panel

The s olar panel takes the leading position in renewable and sustainable energy solutions, and people worldwide are quickly adapting to this technology. Solar

IJRTI

Nov 22, 2022 · Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels,

Solar Panel Recycling Machine & Equipment Manufacturer

Professional manufacturer of solar panel recycling machines and equipment. We provide complete solutions for PV panel dismantling, material separation, and eco-friendly waste

Solar Cells

SINGULUS TECHNOLOGIES'' production equipment is designed for the newest PV cell processes, high throughput and low material and media consumption, thus enabling to

Solar Panel Manufacturing Machine

China Solar Panel Manufacturing Machine wholesale - Select 2025 high quality Solar Panel Manufacturing Machine products in best price from certified

PV Equipment | Semiconductor Materials and Equipment

PV equipment are the tools and machines used in the manufacturing, installation, and maintenance of photovoltaic cells, modules, and systems. Some examples of PV equipment

SMC

SMC,製品情報Product Information WEB Catalog Search by Category Search by Program Search by New Products Search by Theme or Industry Search by Thematic Solutions Search by

Industrial Equipment for Solar Panel

6 days ago · The manufacturing of photovoltaic (PV) solar panels involves critical thermal processes such as glass tempering, coating curing, and metallization

Photovoltaic panel equipment processing

What is quality control & testing in solar module manufacturing? Quality control and testing in solar module manufacturing comprise several key steps,each designed to ensure that every

How Are Solar Panels Made Step by Step

Jun 17, 2024 · How are solar panels made step by step? This detailed guide explains the entire solar panel manufacturing process, from silicon ingot to PV

Photovoltaic Manufacturing Equipment | PV Manufacturing

Aug 9, 2025 · Chemcut Etching Equipment for Solar Panel Manufacturing. Chemcut conveyorized processing systems are available for multiple steps in traditional silicon and alternative solar

Manufacturing Process of Photovoltaic Panels

Aug 18, 2025 · Manufacturing Process of Photovoltaic Panels Until a few years ago, and even today in many parts of the world, the production process of

Solar Panel Manufacturing Process Explained

Apr 29, 2023 · The manufacturing process for solar PV panels typically involves several steps which include; wafer production, cell production, PV module

Solar Cell Making Machine,Automatic Solar

Suposolar is a group company have been engaged in solar PV module manufacturing solutions for more than 15 years focus on serving small and

Photovoltaic Manufacturing Equipment | PV Manufacturing

Aug 9, 2025 · Chemcut Etching Equipment for Solar Panel Manufacturing Chemcut conveyorized processing systems are available for multiple steps in traditional silicon and alternative solar

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · NREL researchers consider the full production processes of solar cells and modules when conducting bottom-up cost modeling. Historical and

Solar Panel Manufacturing: A Comprehensive

Aug 9, 2023 · Introduction to Solar Panel Manufacturing Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to

China Solar Panel Manufacturer,Shingled PV

SUNDTA specializing in manufacturing Solar Panel,Shingled PV Modules and Half Cell Solar Panel. Get best price deals of Bifacial Solar Panel on

Top 24 Photovoltaic Equipment Producers Worldwide

2 days ago · Discover the top 24 global photovoltaic equipment manufacturing companies shaping the renewable energy landscape. This article profiles companies like Trina Solar and JA Solar,

Solar Manufacturing | Advanced Manufacturing

Dec 31, 2024 · Solar Manufacturing NREL is advancing next-generation manufacturing processes and technologies for clean electric power generation

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · Since foundation, Horad has been committed to becoming a leading manufacturer of intelligent PV panel production lines by focusing on the solar panel line R&D, designing,

PV Production Line

The DESERT Technology The J.v.G. Thoma DESERT solar panel is a world-class solar panel backed by extensive expertise and experience (over 10

Solar Electric Supply – Leading Wholesale Solar

Solar Electric Supply, Inc. (SES) is America''s oldest wholesale solar distributor and a premier provider of solar energy products. Founded with the vision of

How are solar panels manufactured? | Solar

Jun 26, 2019 · You know solar panels as the futuristic-looking black or blue rectangles that soak up sunlight and bring down your energy bills. You might

The Solar Panel Manufacturing Process

Aug 19, 2025 · Discover the intricate processes in solar panel manufacturing, from silicon purification to the final assembly and testing.

Solar panel manufacturing process: from cell to

This is the so-called lamination process and is an important step in the solar panel manufacturing process. Finally, the structure is then supported with

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements. Since foundation, Horad has been

Custom Solar Panel Production Line | One-Stop

Shuofeng delivers cutting-edge solar panel production lines (PV/solar module) with 95%+ automation. Scalable from 50MW to 1GW projects. 20% faster ROI

6 FAQs about [Photovoltaic solar panel equipment processing manufacturer]

Who is Supo solar panel manufacturer?

Powered by dyyseo.com SUPO is a top brand solar panel manufacturing equipment manufacturer from China,export fully automatic solar panel production line,solar panel making machine,solar cell tabber stringer,laminator,testing machine and tunrkey line solution,best factory layout plan.

Why should you choose horad solar panel production lines?

We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements. Since foundation, Horad has been committed to becoming a leading manufacturer of intelligent PV panel production lines by focusing on the solar panel line R&D, designing, manufacturing, sales and services.

Do you offer a complete set of PV machines?

We offer a complete set of PV machines covering all solar manufacturing processes. We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements.

What is the market share of solar testing machine?

More than 70% of the market share on solar testing machine and 1 Year Warranty for all the supplied machines. Suposolar is a group company have been engaged in solar PV module manufacturing solutions for more than 15 years focus on serving small and medium factories in PV Industry.

Who is SC solar?

SC Solar’s business has covered all mainstream solar enterprises domestically and abroad, and the products have been exported to 30+ countries and regions around the world. Specializing in R&D, manufacturing, sales and service of intelligent equipment in the solar industry.

Who is Suzhou Shengcheng solar equipment?

Suzhou Shengcheng Solar Equipment Co., Ltd., founded in 2010, is a wholly-owned subsidiary of J.S. Machine (stock code: 000821). Located in Suzhou New District, the company now has over 3,400 employees, among whom more than 900 are R&D personnel, and more than 60 hold master’s degree or above.

Industry Information

- Is there a photovoltaic glass factory in Ukraine

- 1200W portable power station in Estonia

- Power supply for photovoltaic power generation system of Bahrain communication base station

- Venezuela EK 2kWh outdoor power supply

- How many kilograms is the energy storage capacity of a container

- 72v inverter manufacturer

- Lithium battery pack balancing skills

- Testing of super capacitors in communication base stations

- Huawei Guatemala City Mobile Energy Storage Power Supply

- How much does a monocrystalline silicon photovoltaic module cost

- Lithium iron phosphate battery pack for sale

- Energy storage power generation and transmission base station

- What are the application scenarios of photovoltaic energy storage cabinets

- 500W solar grid-connected price

- Charging Energy Storage Solutions

- 220v circuit breaker for sale in Ecuador

- Distributed energy storage prices in Bangladesh

- China wholesale battery and storage distributor

- Trends in solar water pumps

- Photovoltaic panel integrated generator

- Average price of microgrid energy storage system

- House solar inverter for sale in Pretoria

- UPS uninterruptible power supply for Phnom Penh data center

Commercial & Industrial Solar Storage Market Growth

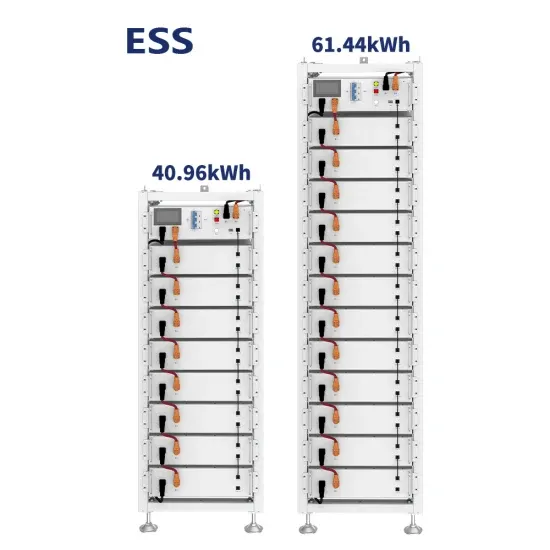

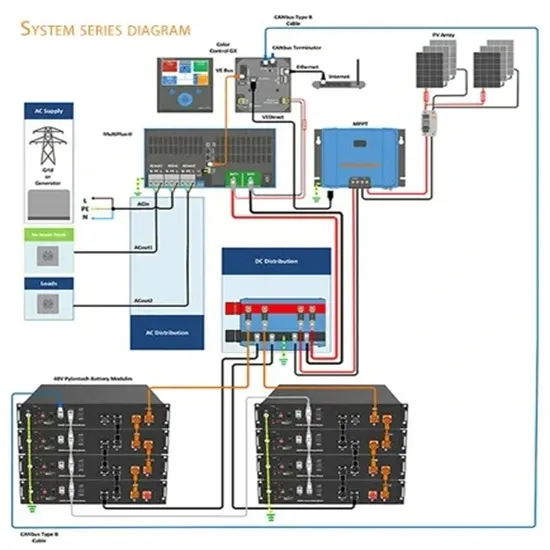

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.