A complete analysis of lithium battery balancing

May 25, 2025 · Lithium battery balancing is a technology that ensures that each single cell in the battery pack maintains similar power and voltage, which can

BMS Board Balance Management: How to

Mar 26, 2025 · Battery Balancing, Why Is It Important? In various electronic devices and new energy applications, batteries are indispensable energy

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

Overview of cell balancing methods for Li‐ion battery

Aug 13, 2020 · There are different techniques of cell balancing have been presented for the battery pack. It is classified as passive and active cell balancing methods based on cell

A complete analysis of lithium battery balancing

May 25, 2025 · Correct use of balancing technology can effectively extend the range of new energy vehicles and reduce performance losses caused by

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · With the advancement of EV technologies, lithium-ion (Li-ion) battery technology has emerged as the most prominent electro-chemical battery in terms of high specific energy

How to Balance Lithium Batteries in Parallel

Sep 26, 2023 · Battery balancing refers to the process of ensuring all individual cells or groups of cells within a battery (or multiple batteries in a system)

Design of Voltage Equalization Circuit and Control Method for Lithium

Jan 31, 2025 · The active equalization of lithium-ion batteries involves transferring energy from high-voltage cells to low-voltage cells, ensuring consistent voltage levels across the battery

Why Proper Cell Balancing is Necessary in

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very

Everything You Need to Know About Battery Balancing

Apr 3, 2025 · In battery systems, cells are often connected in series to achieve higher voltage levels that meet the load requirements. For example, a battery pack consists of 16 individual

What is Cell Balancing for Lithium-ion Battery

Aug 7, 2024 · Proper cell balancing is critical to the efficiency and lifespan of lithium-ion battery packs. As these batteries become increasingly popular in

Battery Cell Imbalance: What it Means (+How to

Jan 15, 2024 · Discover why unbalanced batteries cost more and how Zitara''s innovative solution ensures continuous balancing, maximizing your battery''s

What is Cell Balancing for Lithium-ion Battery

Apr 25, 2024 · Lithium-ion packs, popular for energy density and lifespan, are widely used. Addressing cell balancing is crucial for their performance and safety.

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · How to Connect Lithium Batteries in Parallel Safely? In order to prevent potential hazards and optimize battery performance, it is necessary to

Comparison of Battery balancing methods:

Oct 16, 2023 · Lithium-ion (Li-ion) batteries play a crucial role in various applications, including energy storage and electric vehicles. However, they are

How to Balance Your Lithium Battery Pack During Installation

Jul 25, 2025 · Balancing a lithium battery pack involves aligning individual cell voltages via a BMS (Battery Management System) during installation to prevent capacity fade and thermal risks.

Do Lithium Batteries Need to Be Balanced?-Vatrer

Nov 7, 2024 · Without balancing, these discrepancies can lead to some cells being overcharged while others are undercharged, reducing the overall capacity and efficiency of the battery pack.

Battery Balancer Guide: Optimize Performance

Jul 25, 2024 · Battery balancing and battery balancers are crucial in optimizing multi-cell battery packs'' performance, longevity, and safety. This

Cell Balancing During Charging vs Discharging

Mar 25, 2025 · Wireless Balancing Systems: Newer systems reduce wiring needs and improve battery pack design flexibility. Self-Balancing Cells: Innovations in

What Is Lithium Battery Balancer?

Jun 6, 2024 · In addition to ensuring that the lithium battery pack is not overcharged or over-discharged, the battery management system BMS can

Battery Balancing: What, Why, and How – PowMr

Jan 15, 2025 · Battery balancing is a vital process for maintaining the efficiency, performance, and safety of battery systems, whether for solar energy storage,

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · I. INTRODUCTION Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. Means used to perform cell

Passive Balancing vs Active Balancing in Lithium Batteries

Jun 19, 2025 · Battery balancing methods play a vital role in ensuring the optimal performance and extended lifespan of lithium batteries. When comparing Passive Balancing vs Active

What are Cell Balancing Techniques and How to

Jan 4, 2019 · In this article we will learn about battery cell balancing and also briefly about how to use them on the hardware and software level.

BMS and lithium battery balancing: What is it?

May 25, 2021 · The key function of a lithium battery BMS is cell balancing. What is a conventional BMS and how is the Flash Balancing System different?

Battery Pack Cell Balancing

Battery Pack Cell Balancing This example shows how to implement a passive cell balancing for a Lithium-ion battery pack. Cell-to-cell differences in the module

Essential Guide to LiFePO4 Battery Balancing:

Apr 18, 2025 · Learn the importance of LiFePO4 battery balancing and discover the best methods to ensure your battery pack operates efficiently and safely.

How To Balance A Lithium Batteries: Top and Bottom

Jun 26, 2007 · Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. The means used to perform cell balancing

A Comprehensive Guide to Battery Balancing

Understanding Battery Balancing Battery balancing involves equalizing the State of Charge (SOC) across all cells in a battery pack. This process ensures that

Battery Cell Balancing

Jul 15, 2025 · Battery cell balancing is the process of equalizing charge levels across individual cells in a series-connected battery pack. When lithium-ion or lead-acid batteries charge and

LiFePO4 Cell Balancing & How To Balance

What is LiFePO4 cell balancing and why does it matter? We take a look at how to balance LiFePO4 cells and get teh best out of your battery.

Techniques for Balancing Batteries-Improve

Battery balancing is the process of equalizing the charge among individual cells within a battery or between batteries in a group to maintain consistent voltage

6 FAQs about [Lithium battery pack balancing skills]

What is battery balancing?

Battery balancing equalizes the state of charge (SOC) across all cells in a multi-cell battery pack. This technique maximizes the battery pack’s overall capacity and lifespan while ensuring safe operation.

Does a lithium ion battery have a balance problem?

If you built a lithium-ion battery and its capacity is not what you expect, then you more than likely have a balance issue. While it's true that cells connected in parallel will find their own natural balance, the same is not true for cells wired in series. Battery cells in series have no way of transferring energy between one another.

Do you know how to balance a lithium battery pack?

Whether you are new to battery building or a seasoned professional, it's totally normal to not know how to balance a lithium battery pack. Most of the time when building a battery, as long as you use a decent BMS, it will balance the pack for you over time. The problem is, this can take a very, very long time.

Can you put a Li-ion balancer in a battery pack?

You can also place a li-ion balancer in your pack to perform active cell balancing, increasing the lifetime of your battery pack. When you wire an active balancer in your pack, you want to make sure that the balancer matches the series groups that you have in your pack.

Why is SoC balancing important in EV battery pack?

After performing cell balancing, each cell's SoC reaches 60 % (average SoC) which signifies that all cells have reached to same level or balanced. Therefore, SoC balancing is crucial in EV battery pack to increase the usable capacity. Fig. 3. Charge among five cells connected in series before and after SoC balancing.

Which balancer should I use for a 4S battery pack?

For instance, if you are creating a 4S battery pack, you want to make sure that the balancer you put in is set up for 4S battery packs. Active 3-series balancer for li-ion cells & lifepo4 cells. Active 4-series balancer for li-ion cells & lifepo4 cells. Active 7-series balancer for li-ion cells & lifepo4 cells.

Industry Information

- Cryogenic Energy Storage System

- Single phase breaker factory in Us

- The largest energy storage battery cabinet

- Tunisia Power Plant Air Energy Storage Project

- Palau wind solar and energy storage new energy

- Bolivia solar energy storage battery

- Malaysia Penang photovoltaic folding container villa wholesale

- Royu circuit breaker factory in Angola

- RV Independent Solar System

- Hot sale factory price 33kv switchgear Wholesaler

- Uganda Outdoor Power Supply

- Funafuti Institute of Chemical Engineering Energy Storage Battery Company

- Namibia home solar system grid connection

- Huawei Tuvalu Energy Storage Field

- Koten safety breaker factory in Tanzania

- What is a charge-discharge energy storage battery

- Abkhazia outdoor power bms manufacturer

- Benin Energy Storage System Integration Company

- How many communication base station batteries are there in Indonesia

- Large outdoor base station

- Energy storage power generation mode

- Podgorica lithium energy storage power supply manufacturer

- Mozambique Energy Storage Container Factory Inquiry

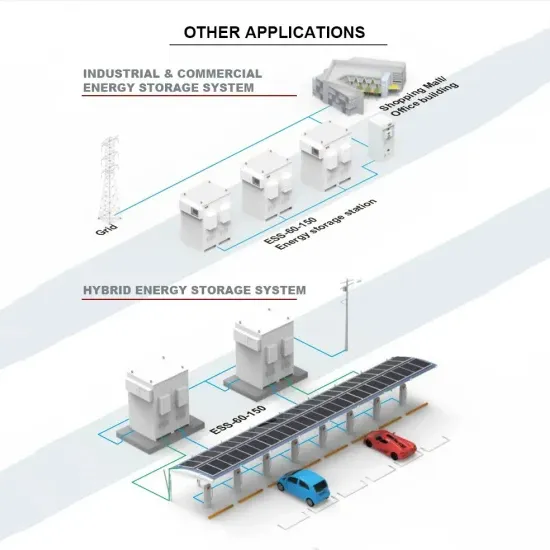

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.