(PDF) Critical review on various inverter

Feb 22, 2021 · This review would be helpful for researchers in this field to select a most feasible inverter for their application, as this study reviews considerable

Refined HERIC-style grid-connected PV inverter utilizing a

Jan 15, 2025 · A generic grid-connected transformerless PV inverter system based on the H4 topology is presented in Fig. 1 (a), with particular attention given to the voltage across the PV

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · In this review, the global status of the PV market, classification of the PV system, configurations of the grid-connected PV inverter, classification of various inverter types, and

From H4, H5 to H6 —Standardization of full-bridge single

Sep 20, 2012 · Leakage current (common mode current) appears through the stray capacitance between the PV array and the grid in transformer-less grid-connected photovoltaic (PV)

Topology of a H4 photovoltaic inverter

In this study, a comparative study between two single‐phase transformerless grid‐connected photovoltaic (PV) inverters, namely H5 and optimised H5

Model of PV inverter in H4 and H5 topologies

Mar 5, 2018 · The PV, H4 inverters without transformers have many advantages like: high reliability and efficiency, low size and weight. However leakage

Improvements to the H5 inverter topology for

Jul 3, 2020 · Incorporation of transformer in grid-photovoltaic (PV) interfaces makes the systems bulky and expensive, and reduces the system efficiency.

Improvements to the H5 inverter topology for

Jan 15, 2021 · The constant CM voltage will cause no CM (i.e. ground-leakage) current through the stray capacitance between the PV array and the ground. Besides, the proposed topology

A New Transformerless Configuration for Grid

Since, the structure of the solar single-phase inverters is based on the H4 configuration, some structures have modified the traditional full-bridge inverter (H4 topology) to have a constant CM

An Optimized H5 Hysteresis Current Control with Clamped

Jan 7, 2025 · Finally, a 2.2 kW grid-connected single-phase HCH5-D2 PV inverter system''s MATLAB simulation is presented, showing better results compared to a traditional H4 inverter.

Comparative performance evaluation of

Jan 1, 2019 · Nowadays, the use of transformer-less single-phase inverters is widespread for domestic photovoltaic applications due to the high efficiency

Unified Control of Bidirectional H4 Bridge Converter in

May 11, 2023 · In the single-phase photovoltaic energy storage inverter, H4 bridge topology is widely used in the bidirectional AC/DC circuit at the grid side because of its simple structure

Comparative performance evaluation of full-bridge, H5,

Dec 22, 2020 · Abstract: Nowadays, the use of transformer-less single-phase inverters is widespread for domestic photovoltaic applications due to the high efficiency that can be

High-Efficiency Single-Phase Transformerless PV H6

Nov 24, 2023 · The traditional full-bridge inverter with four active switches (H4 topology) is simple and has a good tradeoff be-tween efficiency, complexity, and price.

From H4, H5 to H6 —Standardization of full-bridge single

TL;DR: In this paper, a detailed review, investigation, classification and evaluation of full-bridge (H4) single phase PV inverter topologies without ground leakage current is presented, such as

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The most common inverter topologies used in string PV inverters are conventional H4 topology, improved H5 topology, highly efficient and reliable inverter concept (HERIC), and

(PDF) A Comparative Analysis of Transformer-less Inverter

Jan 14, 2025 · Flow of leakage current in H4 inverter Comparative FFT analysis of various inverter topologies: (a) H4 Bipolar, (b) H4 Unipolar, (c) H5 Topology, (d) HERIC Topology Circuit

Comparative analysis of single phase transformerless inverter

Jun 1, 2017 · Many single phase transformerless inverter topologies with reduced leakage current have been introduced for grid tied photovoltaic (PV) applications in the past few years. These

Model of PV inverter in H4 and H5 topologies

The PV, H4 inverters without transformers have many advantages like: high reliability and efficiency, low size and weight. However leakage currents arise

(PDF) A Comparative Analysis of Transformer-less Inverter

Jan 14, 2025 · This paper investigates three topologies H4, H5, and HERIC with comparisons between their CMV, differential-mode voltage (DMV), total harmonic distortion (THD), and

Microsoft Word

Dec 5, 2023 · The PV, H4 inverters without transformers have many advantages like: high reliability and efficiency, low size and weight. However leakage currents arise at such

Comparison of Full Bridge Transformerless H5, HERIC,

Nov 30, 2020 · ABSTRACT: Photovoltaic (PV) generation systems are widely employed in transformer less inverters, in order to achieve the benefits of high efficiency and low cost.

H6‐type transformerless single‐phase inverter

Apr 1, 2015 · In this study, a new H6-type transformerless inverter for grid-tied PV system is proposed that can eliminate the threat of leakage current. The

H5 Transformerless Grid-Connected Photovoltaic Inverter

The H4 inverter gives an unsatisfied output in terms of voltage and current as ob-served in Figure 8 due to the appearance of harmonics and resulted in the distorted current flow which

Novel sorted PWM strategy and control for photovoltaic

Sep 6, 2024 · This paper proposes a novel sorted level-shifted U-shaped carrier-based pulse width modulation (SLSUC PWM) strategy combined with an input power control approach for a

Design of Photovoltaic H6 -Type Transformerless

A comparison was made between the H6 and the traditional H4 and H5 topology and the leakage current in the H6 topology is 42.47mA as opposed to

Unified Control of Bidirectional H4 Bridge Converter in

May 10, 2023 · In this paper, the bidirectional H4 bridge converter in single-phase photovoltaic energy storage inverter adopts the double closed-loop control of voltage outer loop and current

Single-phase transformerless inverter topologies

Apr 1, 2023 · For inverter topologies with less than three levels, the simulation results show that the highly efficient and reliable inverter concept (HERIC)

Novel H6 Transformerless Inverter for Grid

May 21, 2022 · Common mode voltage remains constant in the proposed H6 inverter and hence the leakage current is eliminated. The proposed H6

Conventional H-bridge and recent multilevel inverter topologies

Jan 1, 2021 · PV inverters are commonly implemented in the H-bridge topology in both isolated and nonisolated systems. The H-bridge topology has four switching components in its

6 FAQs about [H4 topology photovoltaic inverter]

Why is H4 bridge topology used in photovoltaic energy storage inverter?

In the single-phase photovoltaic energy storage inverter, H4 bridge topology is widely used in the bidirectional AC/DC circuit at the grid side because of its simple structure and low cost, so as to realize the bidirectional energy flow between the grid and the energy storage battery [4, 5].

What is the difference between H5 and H4 inverter topology?

The H5 inverter topology has a different structure than the H4 topology, with an additional DC-bypass switch (S 5) that disconnects the PV from the grid in freewheeling modes and thus allowing constant CMV. Therefore, the leakage current is smaller than in H4 topology with the bipolar SPWM strategy.

What are H4 and H multilevel inverter topologies?

H4 and recent H multilevel inverter topologies have been investigated related to analysis parameters in nonisolated multilevel PV inverter systems. The performances of the topologies are compared using parameters such as common mode voltage (CMV), leakage current, efficiency, and THD ratios.

What is a H5 inverter?

This topology is called H5 and it was proposed and patented by SMA Solar Technology in 2005 . The H5 inverter topology has a different structure than the H4 topology, with an additional DC-bypass switch (S 5) that disconnects the PV from the grid in freewheeling modes and thus allowing constant CMV.

Why is H4 inverter topology not suitable for nonisolated grid-tied inverters?

H4 inverter topology is not quite suitable for the nonisolated grid-tied inverter, due to leakage current and CMV. The bipolar modulation strategy in the H4 inverter provides constant CMV and it enables low leakage current to be achieved, but the THD ratio and efficiency values of the H4 inverter are undesirable.

Which inverter topology is used in string PV inverters?

Om. Prakash Mahela et al. The most common inverter topologies used in string PV inverters are conventional H4 topology, improved H5 topology, highly efficient and reliable inverter concept (HERIC), and H6 configurations.

Industry Information

- Zagreb Industrial Energy Storage Cabinet

- 4 How much current does a 100W photovoltaic panel have

- Indonesia Energy Storage Battery Industrial Park

- Wall-mounted solar energy storage cabinet installation

- Congo portable outdoor power brand

- Nicosia Energy s outdoor power supply

- How much does a 300W solar street light cost in Eastern Europe

- 5kwh hybrid inverter in China in Albania

- All-vanadium liquid flow battery thin film

- Save energy storage system price

- Battery cabinet cooling station cabinet brand

- Chisinau Investment Group Photovoltaic Glass

- How big is the size of a photovoltaic panel when installed

- What tests do energy storage cabinets need to do

- Factory price solar powerbox in Bhutan

- Can photovoltaic inverters be connected in series

- The function of the base station communication energy storage cabinet connector

- What is the site energy battery cabinet equipment

- Serbia RV Solar System Solution

- Installation Specifications for Industrial and Commercial Energy Storage Cabinets

- How to connect ordinary inverter to the grid

- Solar System Engineering Tax Rate

- Huawei Vietnam Ho Chi Minh PV inverter installation

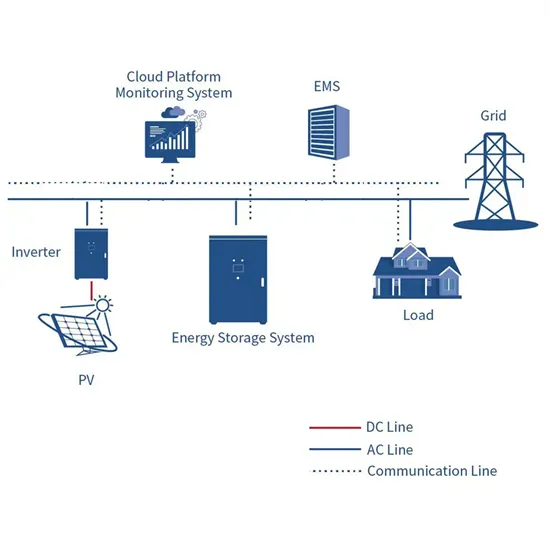

Commercial & Industrial Solar Storage Market Growth

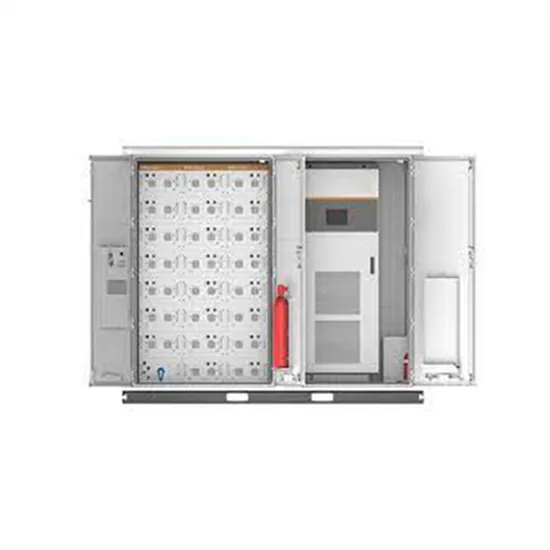

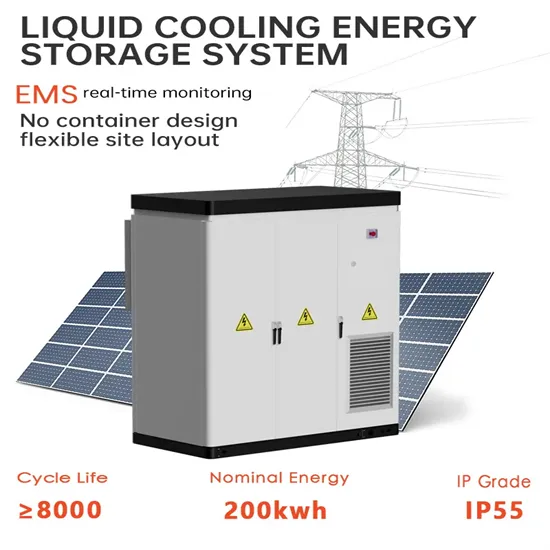

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.