All-vanadium Liquid Flow Battery Graphite Felt

All-vanadium Liquid Flow Battery Graphite Felt Electrode Coating Innovative application of ultrasonic spraying in all-vanadium liquid flow battery graphite

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

Electrodes for All-Vanadium Redox Flow Batteries

Aug 11, 2023 · Therefore, herein, based on deeply insight for mass transport and redox reac-tion processes, electrodes with various enhancing approaches for all-vanadium flow battery are

All-Solid-State Thin Film μ-Batteries for

Aug 5, 2021 · Continuous advances in microelectronics and micro/nanoelectromechanical systems enable the use of microsized energy

Vanadium Redox Flow Battery: Review and

Jul 12, 2024 · Vanadium redox flow battery (VRFB) has garnered significant attention due to its potential for facilitating the cost-effective utilization of

A polydopamine-coated polyamide thin film composite

Mar 1, 2020 · The aim of the study is to increase the stability and selectivity of a polyamide (PA) thin film composite (TFC) membrane (MT) used in a vanadium redox flow battery (VRB). After

Towards a high efficiency and low-cost aqueous redox flow battery

May 1, 2024 · The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow batteries,

Vanadium Flow Battery for Energy Storage:

Mar 28, 2013 · The vanadium flow battery (VFB) as one kind of energy storage technique that has enormous impact on the stabilization and smooth output of

A detachable sandwiched polybenzimidazole-based

Apr 1, 2022 · A cost-effective membrane is critical for commercialization of aqueous redox flow batteries (ARFBs). In this work, we design and fabricate a membrane composed of a thin

Research progress on optimized membranes for

In this case, vanadium redox flow batteries (VRFBs) have emerged as one of the most promising electrochemical energy storage systems for large-scale

Strategy towards high ion selectivity membranes for all-vanadium

Nov 25, 2023 · Vanadium redox flow batteries (VRFBs) have become the most promising and commercially exploited flow batteries among the range of technical solutions for stationary

Thin Film Flow Battery

For thin-film battery systems,surface coatingsare a simple and effective method. Introducing coating materials onto the surface of Ni-rich layered oxides avoids direct contact with the

Enhanced selectivity of SPEEK membrane incorporated

Jan 1, 2025 · 1. Introduction Vanadium redox flow battery (VRFB) provides an efficient technology to efficiently utilize renewable energy, which can solve the problems of instability and

全钒液流电池在充电结束搁置阶段的开路电压变化

Nov 7, 2022 · Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate the open-circuit voltage change during the shelving phase. It is discovered that the open-circuit

Solar vanadium redox-flow battery powered by thin-film

Dec 21, 2018 · In the present study, we inves-tigate all-vanadium redox-flow batteries (VRFB) for solar energy storage and conversion, as they offer several unique advantages compared to

State-of-art of Flow Batteries: A Brief Overview

The commercialized flow battery system Zn/Br falls under the liquid/gas-metal electrode pair category whereas All-Vanadium Redox Flow Battery (VRFB)

Applications of nanocarbons in redox flow batteries

Feb 1, 2021 · An improved thin-film electrode for vanadium redox flow batteries enabled by a dual layered structure [J]. Journal of Power Sources, 2019, 410-411:152-161. [17]

Design of VN anode catalyst towards enhanced kinetics for vanadium flow

Jul 15, 2023 · The all-vanadium flow battery (VFB) constantly suffers from sluggish kinetics for the negative electrodes, restricting its operation ability at high current density. To develop an

Deep neural network-assisted fast and precise simulations of

Feb 1, 2025 · In particular, vanadium redox flow batteries (VRFBs), which eliminate the cross contamination by adopting the same element of vanadium on the negative and positive sides,

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Ether-free polymeric anion exchange materials with extremely low vanadium ion permeability and outstanding cell performance for vanadium redox flow battery (VRFB)

Orientated graphene oxide/Nafion ultra-thin layer coated

Aug 24, 2017 · In this work, orientated GO/Nafion composite membrane with ultra-thin spin-coating layer is fabricated for vanadium redox flow battery. In the ultra-thin GO/Nafion layer,

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · Among them, the all-vanadium redox flow battery (VRFB), which uses the same element as active materials at both negative and positive sides and thus is free of cross

An improved thin-film electrode for vanadium redox flow batteries

Jan 31, 2019 · In this work, we proposed a dual-layer thin-film electrode, consisting of a backing layer and a catalyst layer, for flow batteries. The backing layer with larger pores is adapted to

Solar vanadium redox-flow battery powered by thin-film

Nov 15, 2018 · In the present study, we investigate all-vanadium redox-flow batteries (VRFB) for solar energy storage and conversion, as they offer several unique advantages compared to

Thin-film composite membrane breaking the trade-off

As a result, a vanadium flow battery with a thin-film composite membrane achieves energy efficiency higher than 80% at a current density of 260 mA cm −2, which is the highest ever

Electrodes for All-Vanadium Redox Flow Batteries

Aug 11, 2023 · Flow battery is one of the most promising energy storage systems, due to their rapid responseandexcellentbalancedcapacitybetweendemandandsupply.Especially,the all

A novel flow design to reduce pressure drop and enhance

Feb 1, 2025 · The Vanadium Redox Flow Battery (VRFB) is one of the promising stationary electrochemical storage systems in which flow field geometry is essential to ensure uniform

Investigation of the impact of the flow mode in all-vanadium-redox-flow

Aug 1, 2024 · Energy storage in vanadium redox flow batteries (VRFBs) is significantly impacted by both the cell design and the kinetics of electron transfer at the

Research progress on optimized membranes for

In this review, key aspects related to the polymer electrolyte membranes in VRFBs are summarized, including their functional requirements,

Unbiased solar energy storage: Photoelectrochemical redox flow battery

Apr 1, 2016 · This work proposes a disruptive approach for solar energy storage based on direct conversion of sunlight into electrochemical energy in a redox flow battery. CdS photoeletrodes

Construction of High-Performance Membranes for Vanadium Redox Flow

May 19, 2025 · Critically analyses the ion transport mechanisms of various membranes and compares them and highlights the challenges of membranes for vanadium redox flow battery

Polypyrrole thin film composite membrane prepared via

Dec 1, 2020 · In order to improve the selectivity of porous membrane for vanadium redox flow battery (VRB). A polypyrrole (PPy) thin film composite (TFC) membrane w

Thin Film Flow Battery

The all-solid-state thin-film Li-S battery has been successfully developed by stacking VGs-Li 2 S cathode, lithium-phosphorous-oxynitride (LiPON) solid electrolyte, and Li

Electrode materials for vanadium redox flow batteries:

Jan 1, 2022 · The design and future development of vanadium redox flow battery were prospected. Vanadium redox flow battery (VRFB) is considered to be one of the most

Enhanced Electrochemical Performance of

Nov 21, 2024 · In this study, Li 4 Ti 5 O 12 (LTO) and TiO 2 nanocomposites uniformly were synthesized on the heat-treated graphite felt through (HGF)

6 FAQs about [All-vanadium liquid flow battery thin film]

Can a thin-film composite membrane improve the power density of a flow battery?

The trade-off between ion selectivity and conductivity is a bottleneck of ion conductive membranes. In this paper, a thin-film composite membrane with ultrathin polyamide selective layer is found to break the trade-off between ion selectivity and conductivity, and dramatically improve the power density of a flow battery.

Why are innovative membranes needed for vanadium redox flow batteries?

Innovative membranes are needed for vanadium redox flow batteries, in order to achieve the required criteria; i) cost reduction, ii) long cycle life, iii) high discharge rates and iv) high current densities. To achieve this, variety of materials were tested and reported in literature. 7.1. Zeolite membranes

Can polymeric membranes be used in vanadium redox flow batteries (VRB)?

This review on the various approaches to prepare polymeric membranes for the application in Vanadium Redox Flow Batteries (VRB) reveals various factors which should be considered when developing new membranes materials with or without the addition of non-polymeric materials.

Do low-cost flow batteries have high ion conductivity and selectivity?

Low-cost flow batteries with high power density are promising for energy storage, but membranes with simultaneously high ion conductivity and selectivity should be developed. Here the authors report a thin-film composite membrane that breaks the trade-off between ion conductivity and selectivity.

Why does a vanadium electrolyte deteriorate a battery membrane?

Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor membrane selectivity towards vanadium permeability can lead to faster discharge times of the battery. These areas seek room for improvement to increase battery lifetime.

How durable is a vanadion membrane in multiple charge/discharge cycling?

Also, the electrolyte utilization increases from 54.1% to 68.4%, even at a high current density of 240 mA•cm−2 . Moreover, the durability of the hybrid VANADion membrane in multiple charge/discharge cycling was shown to be similar to that of Nafion 115 and VANADion over the 80–240 mA•cm −2 current density range .

Industry Information

- Sukhumi solar panel signal base station

- 8w water pump can be connected to solar panels

- 5g communication base station construction regulations

- Benefits of Antimony Energy Storage Battery

- Energy storage battery container height

- Huawei India Mumbai Industrial Energy Storage Products

- Samoa base station energy storage battery brand

- What does anchor communication base station wind and solar complementarity mean

- Large-scale battery energy storage power station in the Middle East

- Bifacial high-efficiency photovoltaic modules

- Glass photovoltaic power generation costs

- Tbilisi DC Uninterruptible Power Supply Company

- Why add lithium-ion batteries to solar base stations

- Saudi Arabia 20kw off-grid energy storage power station photovoltaic storage integrated machine

- UPS voltage stabilizer inverter 24 to 220

- Frequency regulation function of energy storage power station

- Vanuatu Energy Storage Power Station New Energy Engineering Design Plan

- Gitega Bay Communication Base Station Inverter

- Single-phase voltage source full-bridge inverter

- How much does Portonovo s energy storage power supply cost

- China Energy Storage Container Manufacturing

- Madagascar energy storage battery customization

- Energy storage charging pile accessories

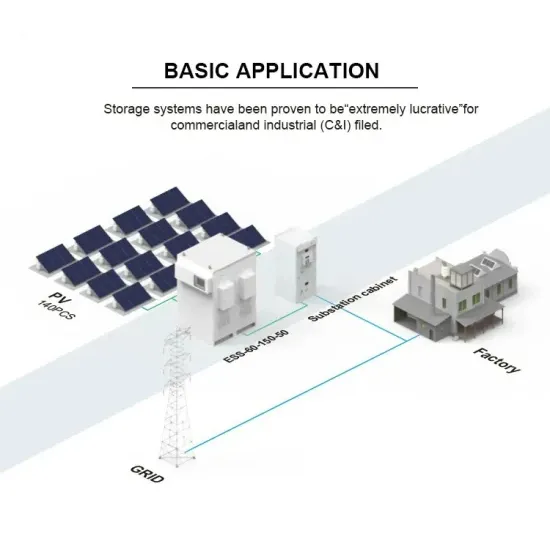

Commercial & Industrial Solar Storage Market Growth

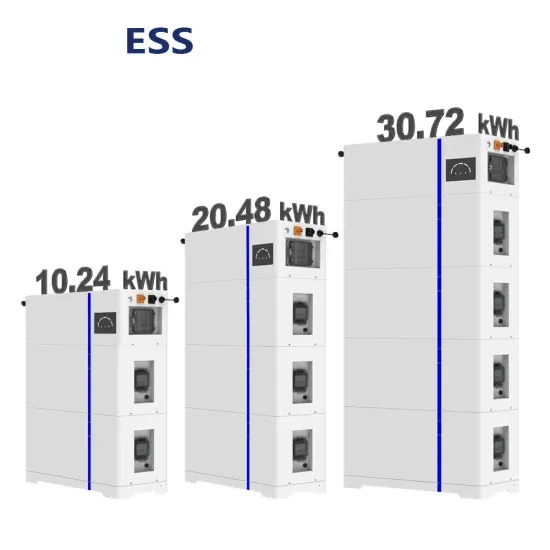

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

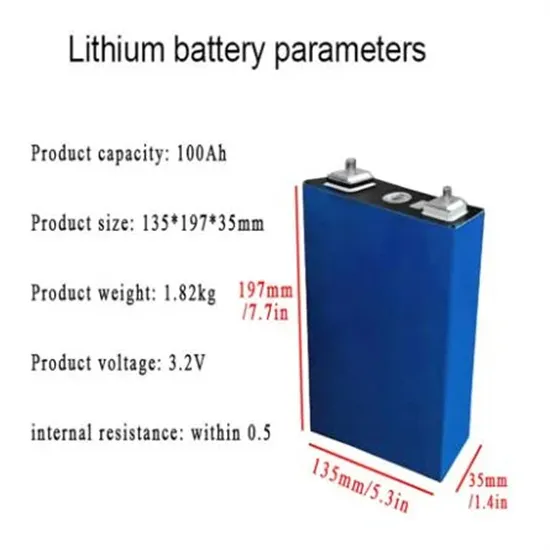

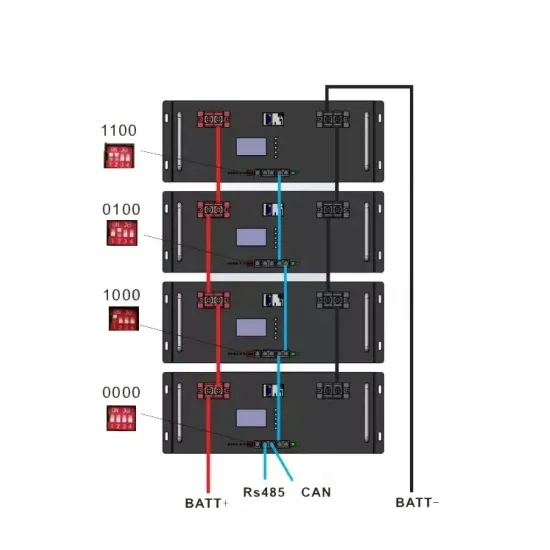

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.