Understanding DC Charging Piles: Benefits

Dec 12, 2023 · It consists of three main parts: 1. Charging Pile: The physical infrastructure that supplies electricity to the EV. DC charging piles are equipped with the necessary hardware to

Lithium battery energy storage charging pile

Among rechargeable batteries, Lithium-ion (Li-ion) batteries have become the most commonly used energy supply for portable electronic devices such as mobile phones and laptop

Battery Energy Storage Systems: Main Considerations for

5 days ago · This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Energy Storage Systems Boost Electric Vehicles''

The charging process of lithium batteries will require a constant current, constant voltage charging profile, where the power required to charge up to 80% of the

What is an energy storage charging pile? | NenPower

Sep 20, 2024 · Unlike traditional charging stations that rely solely on a direct power supply from the grid, energy storage charging piles incorporate battery systems that can store surplus

Iraq charging pile energy storage system

The thermal energy storage battery storage project uses molten salt thermal storage storage technology. The project was announced in 2018 and will be commissioned in 2030. Battery

Gotion High-Tech Launched Semi-Solid-State Battery

Jun 10, 2022 · From May 27 to 28, Gotion High-Tech, a renowned manufacturer of power batteries in China, convened its 11th Technology Conference. The Company launched several

A Review on the Recent Advances in Battery

In general, energy density is a key component in battery development, and scientists are constantly developing new methods and technologies to make

Energy Storage Battery to Charging Pile: The Future of EV

Sep 10, 2019 · The Charging Station of 2030: Sneak Peek Solid-state batteries the size of suitcases powering ultra-fast 350kW chargers. Solar canopies feeding storage systems that

How much energy storage does the charging pile have?

Mar 29, 2024 · Charging piles can utilize various battery types, including lithium-ion, lead-acid, or even emerging technologies like solid-state batteries. Each varies in energy density, lifespan,

Are current energy storage charging piles lithium batteries

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Energy Storage Charging Pile Management Based on

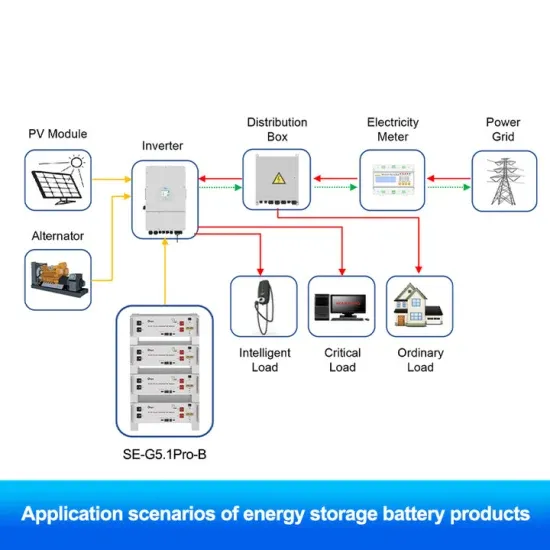

May 19, 2023 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

How does the energy storage charging pile interact with the battery management system? On the one hand,the energy storage charging pile interacts with the battery management system

Energy storage charging piles do not use lithium batteries

1 · Explore the exciting potential of solid state batteries in our latest article, which examines their advantages over traditional lithium-ion technology. Discover how these

How much does a battery energy storage

Mar 19, 2024 · A battery energy storage charging pile functions as an energy gateway, capturing and storing excess electrical energy for later use. Typically

Nano-ion electric energy storage charging pile

Optimal sizing, location, and control of energy storage to manage diurnal and seasonal solar variations in order to meet EV charging requirements; Charging electric vehicles from solar

What are the energy storage charging piles?

Aug 9, 2024 · 2. TECHNOLOGICAL INNOVATIONS The technological advancements underpinning energy storage charging piles are noteworthy

What are the energy storage charging piles?

Aug 9, 2024 · Energy storage charging piles utilize innovative battery technologies to store excess energy generated during peak production times.

energy storage charging pile battery

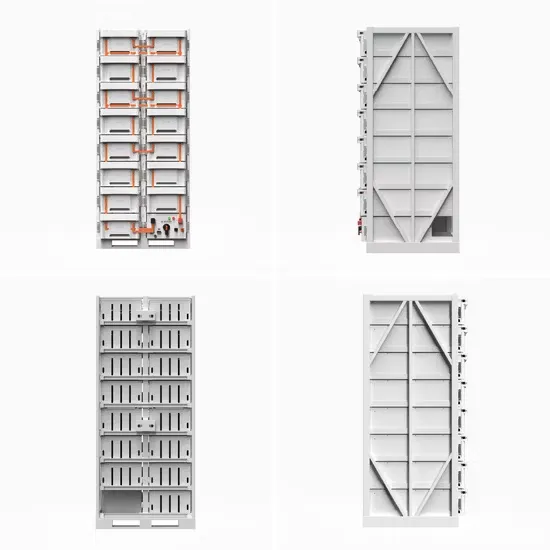

The battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage;

Energy Storage Technology Development Under

Dec 18, 2020 · Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy

Energy Storage Charging Pile Management Based on

Jan 16, 2024 · In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,...

Energy Storage Charging Pile Containers: The Future of EV Charging

Enter energy storage charging pile containers – the Swiss Army knives of EV infrastructure. These modular systems combine lithium-ion batteries, smart grid tech, and rapid chargers in

Lithium-ion energy storage charging pile classification

The Federal Energy Management Program (FEMP) provides a customizable template for federal government agencies seeking to procure lithium-ion battery energy storage systems (BESS).

Grid-Scale Lithium-Ion Energy Storage Solutions

3 days ago · Local Manufacturing: Countries are constructing gigafactories to create and secure their supply chain. Conclusion: Lithium-Ion Forms the

Guangzhou Aipark Energy Storage Project

Aug 18, 2025 · By leveraging the Cloud Platform for Energy Storage, it collects real-time data on charging pile loads and grid price signals, dynamically adjusts discharge power (Dynamic

Lithium battery car energy storage charging pile

Energy Storage Systems Boost Electric Vehicles'''' Fast Charger The upper voltage limit is set to 1000 V dc for safety reasons when the output connector is plugged into the vehicle. While

How Lithium-ion Batteries Work | Department of

Feb 28, 2023 · Lithium-ion batteries power the lives of millions of people each day. From laptops and cell phones to hybrids and electric cars, this technology

Ignite the energy storage charging pile light

The EPLUS intelligent mobile energy storage charging pile is the first self-developed product of Gotion High-Tech in the field of mobile energy storage and charging for ordinary consumers. It

Advancing energy storage: The future trajectory of lithium-ion battery

Jun 1, 2025 · Lithium-ion batteries have revolutionized the way we store and utilize energy, transforming numerous industries and driving the shift towards a more sustainable future.

What materials are used to store energy in

Feb 26, 2024 · Charging piles typically employ several types of batteries, with lithium-ion, lead-acid, and nickel-metal hydride being the most prevalent.

6 FAQs about [Energy storage charging pile lithium battery]

Can battery energy storage technology be applied to EV charging piles?

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging, and storage; Multisim software is used to build an EV charging model in order to simulate the charge control guidance module.

How a charging pile energy storage system can improve power supply and demand?

Charging pile energy storage system can improve the relationship between power supply and demand. Applying the characteristics of energy storage technology to the charging piles of electric vehicles and optimizing them in conjunction with the power grid can achieve the effect of peak-shaving and valley-filling, which can effectively cut costs.

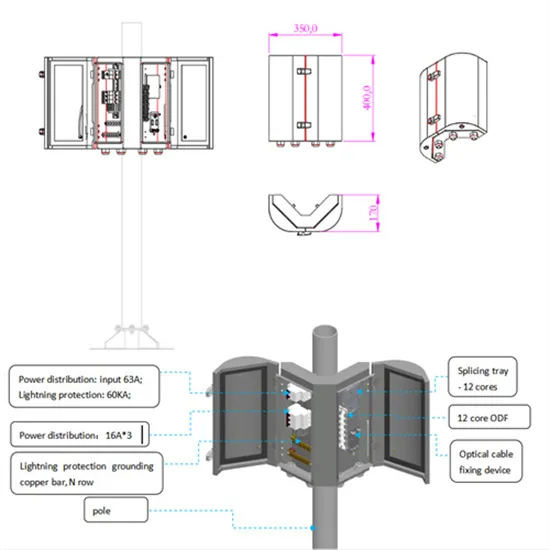

What are the parts of a charging pile energy storage system?

The charging pile energy storage system can be divided into four parts: the distribution network device, the charging system, the battery charging station and the real-time monitoring system [ 3 ].

Are lithium-ion batteries a viable energy storage technology?

Lithium-ion batteries have become the dominant energy storage technology due to their high energy density, long cycle life, and suitability for a wide range of applications. However, several key challenges need to be addressed to further improve their performance, safety, and cost-effectiveness.

What is the function of the control device of energy storage charging pile?

The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to charge the energy storage battery as far as possible when the electricity price is at the valley period. In this section, the energy storage charging pile device is designed as a whole.

What are electric vehicle charging piles?

Electric vehicle charging piles are different from traditional gas stations and are generally installed in public places. The wide deployment of charging pile energy storage systems is of great significance to the development of smart grids. Through the demand side management, the effect of stabilizing grid fluctuations can be achieved.

Industry Information

- Belgian container distribution cabinet manufacturer

- Sukhumilo home grid all-vanadium liquid flow battery energy storage

- Is it okay to put a battery cabinet in the office

- How much electricity is equivalent to 18w milliampere of outdoor power supply

- Solar power station portable in Panama

- How much is the price of micro inverter in Samoa

- Factory Solar Panel System

- How big a battery should I use for 580 watts of solar energy

- Uninterruptible power supply is placed in the cabinet

- Madagascar photovoltaic glass sun room installation

- 5kva inverter system for sale in Auckland

- 220V outdoor power supply in West Asia

- Wholesale 200w power inverter in El-Salvador

- Base station battery level

- Ultra-small 12V outdoor power supply

- Pack battery in Manchester UK

- Power cabinet for 5g communication base station

- Liquid Cooling Energy Storage Investment

- Which battery is better for connecting the inverter to the communication base station

- High quality ashapower inverter

- Brazilian energy storage system manufacturers

- Solar lights household appliances

- Juba battery energy storage container manufacturer

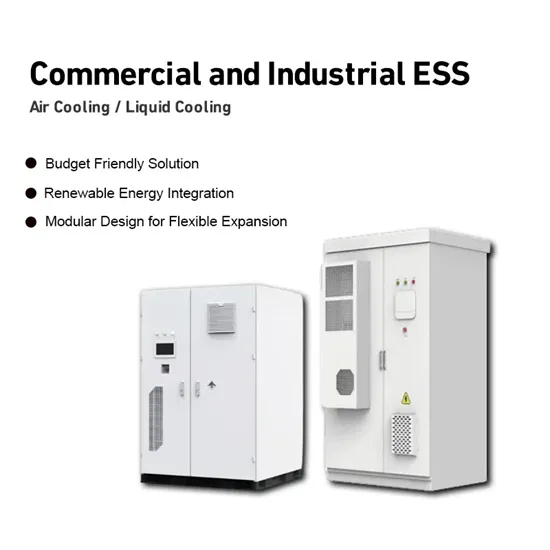

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.