Powering Arduino With a Battery

Powering Arduino With a Battery: Make your Arduino projects portable by using a battery for power. From the Uno and Mega documentation pages: "The board

Batteries and Chargers Connected in Series and Parallel

Learn how to connect batteries in series and parallel for different voltage and amp-hour capacities. Battery Tender® offers detailed instructions and diagrams for safely charging and configuring

Can You Link Battery Packs? Understanding Series Vs. Parallel

Apr 11, 2025 · Can You Link Battery Packs Together? Yes, you can link battery packs together. However, it is important to consider how you connect them to avoid potential issues.

Series, Parallel, and Series-Parallel Connections of Batteries

Learn battery connections: series, parallel, and series-parallel setups. Ensure safety, maximize performance, and extend battery lifecycles.

How to Use Magsafe Battery Pack

Learn how to use MagSafe Battery Pack with our ultimate guide. From aligning and attaching to your iPhone to tips for optimized charging, we cover it all.

How To Hook up and Install A BMS To Battery

Oct 15, 2022 · In this article, we will discuss how to attach a BMS to a lithium-ion battery. We will also go over each connection and explain what they all mean.

Connecting batteries in series – BatteryGuy Knowledge

May 3, 2024 · Connecting batteries of different amp hour ratings in series In theory a 6 volt 3 Ah battery and a 6 volt 5 Ah battery connected in series would give a supply of 12 volts 3 Ah (the

Types of Battery Terminal Connectors: A

Apr 18, 2025 · Discover the various types of battery terminal connectors, their applications, and tips for choosing the right connector for secure and reliable

Battery Pack & Configuration

Dec 31, 2024 · Battery Pack & Configuration The battery system combines many cells and other control electronics into a full battery to power the EV.

Battery Connection

The potential for burns or even fire in the event of a low-reistance connection between the positive and negative terminals of the battery pack. To use PackProbe, first connect the Arduino

Connecting batteries in parallel – BatteryGuy

May 3, 2024 · for secondary (rechargeable) batteries – the stronger battery would charge the weaker one, draining itself and wasting energy. If you connect rechargeable batteries in

Connection Parts in BEV Battery Packs

Apr 24, 2024 · These connection parts play a significant role in improving the performance of the battery packs by ensuring compact size, space efficiency, and high current capacity. This

Battery Packs In Series Or Parallel: Key Differences And

Mar 28, 2025 · Connecting battery packs in series increases the output voltage while keeping the capacity the same. In contrast, wiring them in parallel boosts the total capacity without

How to Connect Battery to Motor

Apr 5, 2025 · Learn how to connect a battery to a motor with this easy-to-follow guide. Perfect for DIY enthusiasts and beginners.

Guide: Connecting BMS to 18650 and 21700 Lithium-Ion Cells

Proper connection of a BMS to your battery cells is crucial for the safety and efficiency of your battery pack. This guide will walk you through the process of connecting a BMS to 18650 and

BU-302: Series and Parallel Battery Configurations

Larger packs need custom circuits, and this applies to e-bike batteries, hybrid cars and the Tesla Model 85 that devours over 7000 18650 cells to make up

Connection Method and Precautions of Pack Battery Pack

Apr 10, 2024 · This article will introduce the connection mode of Pack battery Pack, including series connection and parallel connection, and matters needing attention in the connection

How to Wire a Battery Pack from Start to Finish?

Jun 23, 2025 · Connecting batteries into a battery pack allows you to increase voltage, capacity, or both to power devices requiring more electrical power.

ESS-240V12-9AhBPVBA03 Modular Battery Pack Quick Guide

Jan 18, 2019 · battery strings can connect to a maximum of four battery packs. This document describes how to install battery packs for a 6 kVA UPS. 1. The two battery ports on a battery

Busbar design application note

May 15, 2023 · In battery packs for electric mobility, a busbar is used to connect battery cells or modules. In automotive battery packs, busbars are used to connect battery modules together.

Expand The Battery Capacity Of A Jackery With A Battery Pack

Feb 23, 2024 · Expand the battery capacity of your Jackery Explorer 1000 Plus, 2000 Plus, or 5000 Plus with a battery pack. Here''s everything you need to know to get started.

How To Hook up and Install A BMS To Battery

Oct 15, 2022 · This wire needs to be just as thick as the B- wire, and you can attach it to the battery pack using the same trick described for the B-

How to Wire a BMS to Your Battery Pack

Wiring a bms to a battery pack is not a difficult thing, we explain it step by step to help you connect the bms successfully.

Powering Up Safely: How to Wire Batteries in Series

Nov 15, 2023 · Wiring lithium-ion batteries in series is a common practice to increase overall voltage, but requires careful attention to detail and adherence to safety guidelines. Always

Can I Connect to Battery Packs of Different Capacities? Risks,

Apr 5, 2025 · In summary, while connecting battery packs of different capacities is possible, it requires caution and adherence to best practices. Now, let''s explore the specific steps you can

How To Connect Batteries In Series and Parallel

Feb 9, 2025 · Connect the Cells: Use a high-voltage laser welding machine (2KW or 6KW) to weld cells in series or parallel configurations. Attach Nickel Strips: Weld nickel or aluminum strips to

Electric Vehicle Battery Connectors

Aug 19, 2025 · Electric vehicle battery management systems (BMS), battery packs and cell-to-battery applications require a suite of rugged, reliable

How to Assemble a Battery Pack with a BMS

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Making a Li-Ion battery pack

Jun 6, 2020 · Your pack is now finished: Since we used Samsung INR21700-50E cells, this battery pack is a 2S pack with 5000 mAh. Even though these are Li

How to Connect a BMS to Your Battery Pack

Apr 30, 2025 · Learn how to connect a BMS to your battery pack with our step-by-step guide. Ensure safety, efficiency, and longevity for your lithium-ion batteries.

How to Connect Two Batteries in Parallel?

Mar 19, 2025 · Learn how to connect two batteries in parallel, increase capacity, and avoid common mistakes. Perfect for DIY enthusiasts and tech lovers. Get

Parallel then Series or Series then Parallel

Sep 29, 2023 · How should you connect battery cells together: Parallel then Series or Series then Parallel? What are the benefits and what are the issues

6 FAQs about [Connect battery pack]

Can I connect a battery pack to one battery pack?

You CAN connect your load to ONE of the batteries, which will drain both equally. However, the preferred method for keeping the batteries equalized is connecting to the positive at one end of the battery pack and the negative at the other end.

How do you insulate a battery pack?

Attach Nickel Strips: Weld nickel or aluminum strips to connect the cells securely. Integrate the BMS: Weld the BMS to the battery pack, ensuring all connections are precise and insulated. 4. Insulate and Secure the Pack Wrap the Pack: Use insulating materials like fish paper or heat shrink tubing to protect the cells and connections.

How do you connect a BMS to a battery pack?

Connecting the BMS: B- Terminal: Connect to the main negative (-) terminal of the battery pack. B+ Terminal: Often already connected internally; check your BMS specifications. B1 (or B0): Connect to the most negative point (first cell's negative terminal). B2, B3,: Connect sequentially to the positive terminals of each cell in series.

How do you Weld a battery pack?

Connect the Cells: Use a high-voltage laser welding machine (2KW or 6KW) to weld cells in series or parallel configurations. Attach Nickel Strips: Weld nickel or aluminum strips to connect the cells securely. Integrate the BMS: Weld the BMS to the battery pack, ensuring all connections are precise and insulated. 4. Insulate and Secure the Pack

How do you connect a battery in a series?

To connect batteries in a series, a jumper wire connects a battery's negative terminal to another battery's positive terminal. This leaves you with a positive terminal at the beginning of the battery pack and a negative terminal at the end of the battery pack for your application.

How do I connect a battery charger?

The blue wire W1 must be connected to the opposite end of the battery pack as the black wire at the top of the battery pack. When batteries are connected in parallel, only use one charger. Do not connect a charger to each battery, unless you break the electrical connection between the batteries.

Industry Information

- Panama Liquid Flow Energy Storage Battery

- Lobamba photovoltaic panel grid-connected manufacturer

- Photovoltaic glass strengthens

- Slovenia 5G communication base station energy management system project

- Backup energy storage battery in Toronto Canada

- Avaru Solar PV Panel Inverter

- Bulgaria Outdoor Communication Battery Cabinet Factory 372KWh

- Double glass and single glass modules

- Majuro new supercapacitor price

- Photovoltaic panel silicon size

- Desert power generation and energy storage

- How much does a microgrid energy storage system usually cost

- Sanaa communication base station lead-acid battery photovoltaic power generation outdoor unit

- Guatemala City AP Telecom Battery Cabinet

- How much does the Palestinian phase change energy storage system cost

- Nauru s largest battery energy storage battery manufacturer

- 318 How many degrees of outdoor power supply should I buy

- 12V 220V 200W inverter

- Communication base station power supply communication protocol

- Ask for the price of a new inverter

- 30kw hybrid inverter in China in Gambia

- Energy storage production and manufacturing project landed

- Al hassan switchgear for sale in Kyrgyzstan

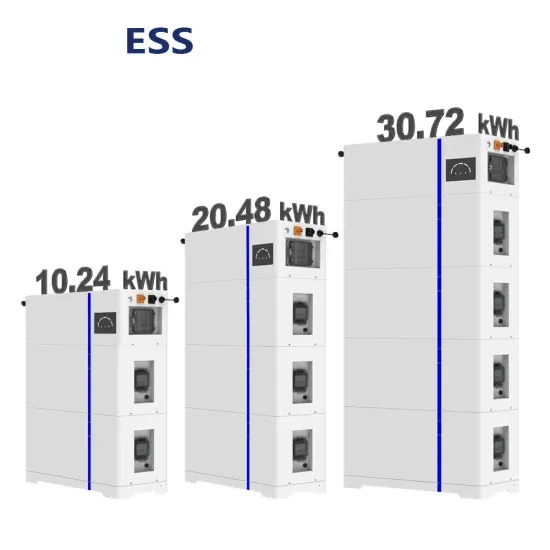

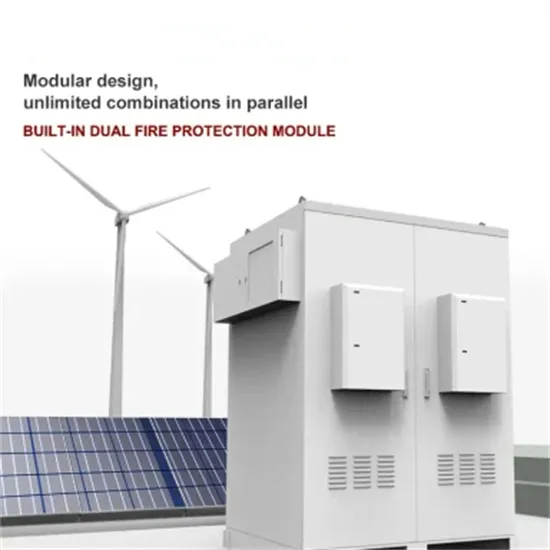

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

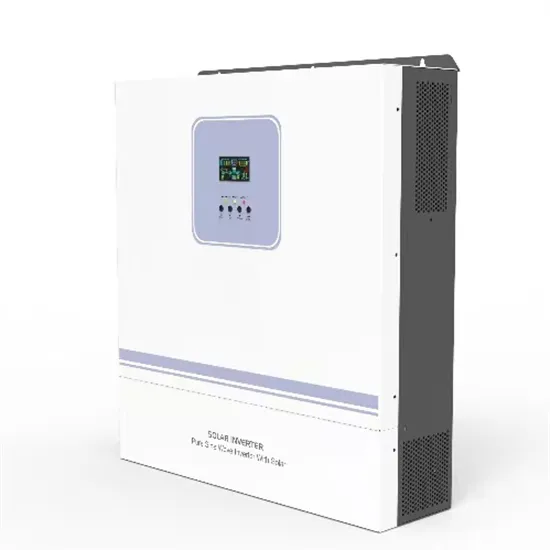

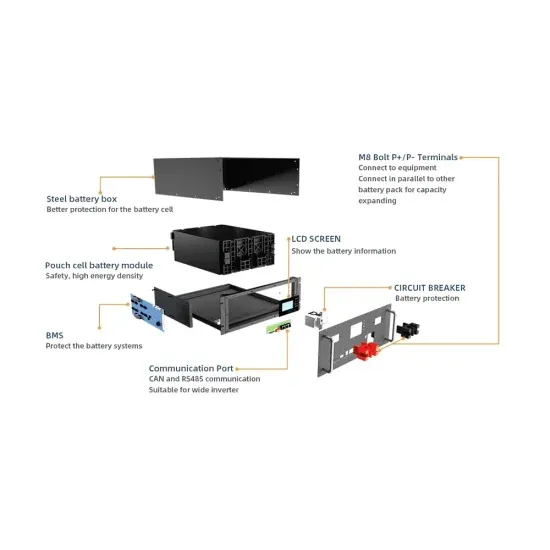

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.