the solarblogger: PV Cell Formats and Size Guide

Mar 5, 2021 · As silicon prices have fallen, the economics has moved decisively in favour of cutting to make a cell with a more perfect square shape, driving up

A Guide to Solar Panel Dimensions

Mar 2, 2024 · Note that costs per watt might climb to as much as $3.50 when you include them in things like labor and rent. Also See: What is Monocrystalline

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Trends of Solar Silicon Wafer Size and Thickness

Mar 31, 2025 · Technological limitations and efficiency considerations vary depending on cell technology: Current mainstream wafer thickness: 150 to

Longi claims world''s highest efficiency for silicon

Apr 14, 2025 · Chinese PV module maker Longi has revealed that its proprietary hybrid interdigitated back contact (HIBC) crystalline silicon solar cell based on

Most efficient solar panels 2025

Jul 24, 2025 · As explained below, solar panel efficiency is determined by two main factors: the photovoltaic (PV) cell efficiency, which is based on the solar

Standardized PV Panel Size Gets Unanimous Votes

Jul 10, 2023 · Standardized PV Panel Size Gets Unanimous VotesAmidst multi-million marketing by manufacturers over the best silicon wafer sizes for solar

Crystalline Silicon Photovoltaics Research

4 days ago · DOE supports crystalline silicon photovoltaic (PV) research and development efforts that lead to market-ready technologies.

Photovoltaic panel silicon wafer specification size drawing

About Photovoltaic panel silicon wafer specification size drawing As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic panel silicon wafer specification size

Crystalline Silicon Photovoltaics

Crystalline Silicon Photovoltaics Characteristics of crystalline silicon photovoltaics Crystalline silicon photovoltaics is the most widely used photovoltaic

Technical properties of Onyx Solar Photovoltaic

4 days ago · While Low-E photovoltaic glass configurations are nearly limitless, the table below highlights our most popular crystalline and amorphous silicon

Evolution of Silicon Wafer Size

Jan 14, 2022 · Over the years, the silicon wafer size has experienced a process from small to large. The increase in silicon wafer size and the continuous progress of photovoltaic

Silicon Wafer Size Standardization Update

Aug 21, 2023 · 6 solar PV manufacturers have announced an agreement over using a standardized silicon wafer size of 191.Xmm For 72-cell modules, they

5 Key Factors That Determine Solar Panel Size

Jun 7, 2024 · Solar panel size is influenced by cell efficiency, intended use, installation space, material advances, and required power output, each dictating design and dimensions Solar

Longi unveils 700 W back-contact PV panel with

Jun 12, 2025 · Chinese solar manufacturer Longi unveiled a new PV module with 25.9% efficiency at the 2025 SNEC trade show this week in Shanghai,

Photovoltaic silicon panel size standard specification

Photovoltaic silicon panel size standard specification What are the specifications of polycrystalline solar PV modules? The specifications are as follows- 1. Efficiency: The 5-busbar cell design in

Photovoltaic silicon panel size specification table

silicon cell PV panels in two sizes: 83W and 180W. The laminated cells are mounted cifications. 2-Battery Bank is the heart of the We used Equation 4 to determine the solar PV panel

Solar PV Panels Market Size to Surpass USD

Jul 17, 2025 · The solar PV panels market size reached at USD 184.29 billion in 2024 and is predicted to surpass around USD 384.44 billion by 2034 with a

Comprehensive Review of Crystalline Silicon

Dec 20, 2023 · This review addresses the growing need for the efficient recycling of crystalline silicon photovoltaic modules (PVMs), in the context of global

Silicon Solar Cell

Silicon solar cells are defined as photovoltaic devices made from crystalline silicon, which are characterized by their long-term stability, non-toxicity, and abundant availability. They

From M0 to M12 – different wafer sizes in the

Dec 13, 2019 · When you talk to the pioneers of the German PV industry, such as Mr. Udo Möhrstedt or the first participants of the symposium at Banz

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Photovoltaic panel silicon wafer size standard

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow''s rigid,flexible,and portable solar panels use the highest quality

CRYSTALLINE SILICON PHOTOVOLTAIC

3 days ago · Crystalline silicon or (c-Si) is the crystalline forms of silicon, either polycrystalline silicon (poly c-Si), or monocrystalline silicon (mono c-Si). It

A comprehensive review on the recycling technology of silicon

Apr 5, 2024 · With the aim of realizing the goals of the Paris Agreement, annual solar power generation on a global scale using silicon PV panels had exceeded 1000 TWh by the end of

Photovoltaic panel silicon wafer specifications and

What size is a monocrystalline silicon wafer? Before 2010,monocrystalline silicon wafers were dominated by 125mm x 125mm width (165mm silicon ingot diameter) and only a small number

What Size Are Solar Panels? A Comprehensive

Feb 26, 2025 · These enhancements render photovoltaic systems more reachable and appealing for property owners, highlighting the significance of

Photovoltaic panel silicon wafer size standard

Solar PV manufacturers have officially started efforts to establish a new ''''M10'''' (182mm x 182mm p-type monocrystalline) large-area wafer size standard to reduce manufacturing costs

Wafer Sizes – PV-Manufacturing

5 days ago · With wafer manufacturers pushing the size of the silicon ingots, 2 different types of wafers were produced, M1 and M2. With only a marginal

Solar Silicon Wafer Size M0 M2 G1 M6 M10 G12

Jan 8, 2024 · In 2022, the combined market share of large-size silicon wafers represented by 182mm (M10) and 210mm (G12) has exceeded 80%. Large

Photovoltaic panel silicon wafer specifications and

Important note: The 210mm size silicon wafer and module size standardization proposition is an attempt to standardize the entire industry chain, including module products. 1.1

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

Trends of Solar Silicon Wafer Size and Thickness

March 31, 2025 Trends of Solar Silicon Wafer Size and Thickness for Different Cell Technologies By Jun Chen, Gyou Seong Park, Øyvind Nielsen, RAAMS

Understanding Solar Panel Sizes and Wattage: A

Feb 20, 2025 · Furthermore, with over 2,500 utility-scale photovoltaic (PV) electricity-generating facilities in the United States, the demand for this

Size of single crystal silicon photovoltaic panels

Thin-film solar panels are photovoltaic (PV) solar cells constructed of thin layers of a semiconductor material such as amorphous silicon, cadmium telluride, or copper indium l

Solar Cells: Size, Process and Technology Explained

Solar Cells: Size The core of photovoltaic solar panels solar cells, divided into monocrystalline solar cells and polycrystalline solar cells, because of

Solar Photovoltaic Panel Manufacturing Market

2 days ago · Global Solar Photovoltaic Panel Manufacturing market size is expected to reach $439.62 billion by 2029 at 11.9%, segmented as by

Recycling Si in waste crystalline silicon photovoltaic panels

Aug 20, 2023 · The photovoltaic (PV) market started in 2000, and the first batch of crystalline silicon (c-Si) PV panels with a lifespan of 20–30 years are about to be retired. Recycling Si in

the solarblogger: PV Cell Formats and Size Guide

Mar 5, 2021 · Here''s a handy diagram I created to help show the difference between all the new solar PV cell formats in the market right now.

5 FAQs about [Photovoltaic panel silicon size]

What is large-size silicon technology?

Large-size silicon technology refers to the use of large-size silicon wafers in the production of cells and modules, so as to reduce the loss in the energy conversion process, improve the efficiency of solar cells and module power.

What are the different solar wafer sizes in 2024?

In 2024, the solar industry featured a variety of wafer sizes: M10 (182mm square wafers): 23% market share. M10 Near Rectangular (182×182mm to186mm): 30% market share. M10R (182×199mm): 12% market share. G12 (210mm square wafers): 17% market share. G12R (210×182mm): 14% market share. G12 half cut (210×105mm): 3% market share.

How are monocrystalline solar cells made?

Monocrystalline cells are made by slicing across a cylindrical ingot of silicon. The least silicon waste is created by having perfectly round cells, but these don't pack very neatly into a solar panel (or module), leaving gaps between the cells which reduce the power output of the panel compared to one that fills the area more effectively.

What are the different types of silicon wafer sizes in 2022?

According to CPIA statistics, in 2022, there are various types of silicon wafer sizes on the market, including 156.75mm, 157mm, 158.75mm, 166mm, 182mm, 210mm, etc., and each occupies a certain market share. In 2022, the combined market share of large-size silicon wafers represented by 182mm (M10) and 210mm (G12) has exceeded 80%.

What is the standard size for m2 solar cells?

After a long period of standardisation on the M2 cell format of 156.75mm, manufacturers cannot agree on a standard size going forward, with each proposing a slightly different format, and of course this means that the finished solar PV modules that the cells are assembled into also differ in size.

Industry Information

- Swedish EK 30 degree photovoltaic energy storage battery

- Asuncion New Energy Storage Container Production Company

- Communication Engineering Design Photovoltaic and Design Wireless Base Station

- How many batteries does the pack require

- Africa outdoor energy storage cabinet solar energy

- How thick is the double glass module

- Ultra-thin photovoltaic glass brand

- Uninterrupted power supply for communication base station pb

- Lithium battery station cabinet base station energy principle

- Guinea-Bissau rural solar power generation system field

- High quality wholesale 4000 amp switchgear distributor

- Lithium for Astana energy storage batteries

- Non-standard double-glass photovoltaic modules

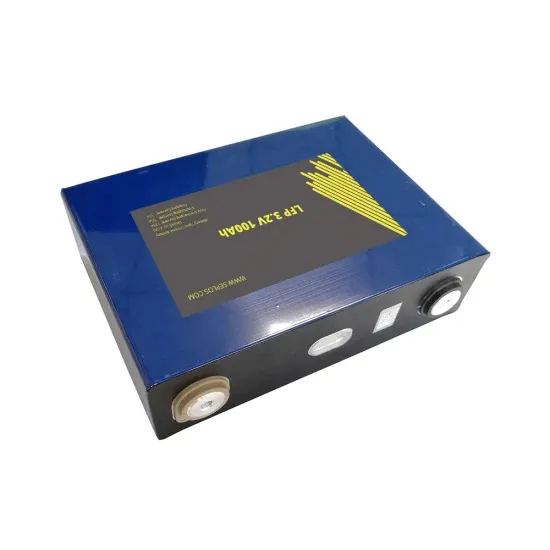

- 80kWh lithium iron phosphate battery pack

- Can the inverter voltage be adjusted higher

- Container Energy Storage Cabinet

- Sri Lanka Green Energy Storage System

- Best wholesale smes energy storage Wholesaler

- Container energy storage factory base station power generation

- Lithium battery pack type

- Tunisia lithium battery pack factory

- Three-phase inverter mtalb

- 24 volt universal inverter

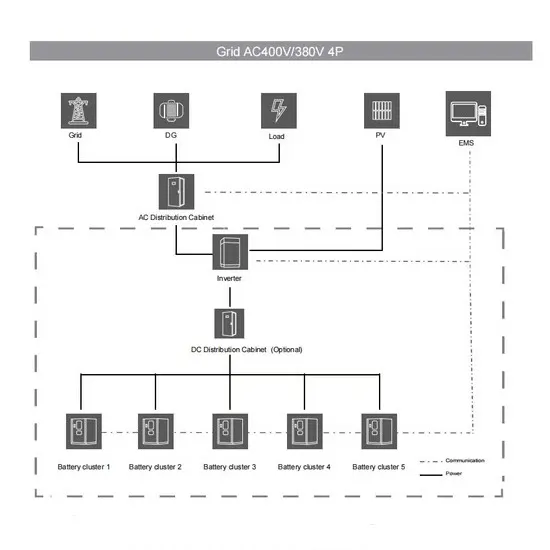

Commercial & Industrial Solar Storage Market Growth

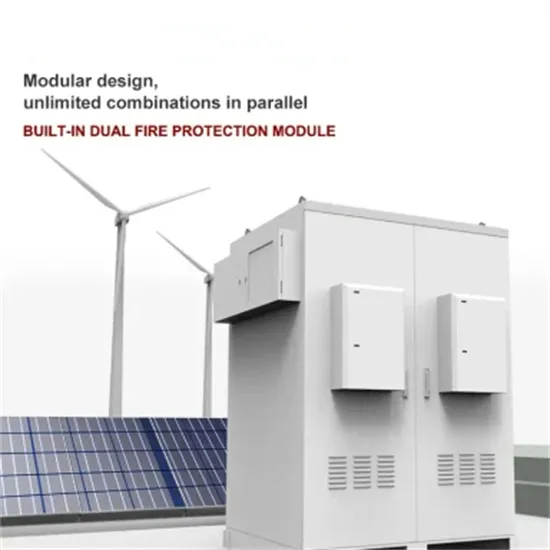

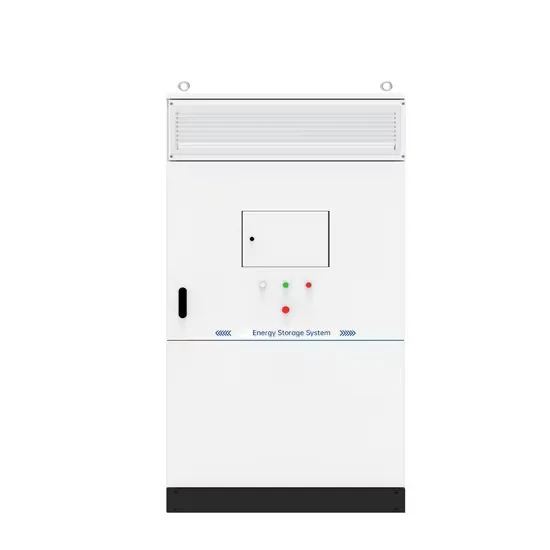

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.