Study on the application of energy storage system in

Mar 10, 2024 · In order to study the transmission efficiencies of main compo-nents inside the combined wind turbine and storage system, a sim-plified schematic of both wind turbine and

Research on the characteristics of hydraulic wind turbine

May 1, 2021 · Abstract A design scheme of hydraulic wind turbine with multi-accumulator is presented to smooth the output power. The mathematical models of the impeller, hydraulic

Integrated dynamic analysis of a spar floating wind turbine

Dec 1, 2022 · The hydraulic system is coupled with the aero-hydro-elastic code HAWC2 through an external dynamic link library. The dynamic responses of a 5 MW spar floating wind turbine

Modeling, simulation and control of a wind turbine with a hydraulic

Sep 17, 2012 · A complete mathematical model of a hydraulic transmission concept for use in wind turbines is presented. The hydraulic system transfers the power from the nacelle to

Hydrostatic Transmissions: A Power Play in Wind

The basic design employs a slow-turning pump connected to the turbine shaft to transfer the power into a high-pressure oil flow. Hydraulic motors then convert

Hydraulic Wind Turbines

In contrast to conventional wind farms, Delft Offshore Turbines are designed to operate in clusters of multiple turbines, collectively pressurizing sea water to a

Schematic of a wind turbine with hydraulic

This paper describes numerical modeling and analysis of wind turbines with high-pressure hydraulic transmission machinery. A dynamic model of the hydraulic

Analysis of a Wind Turbine Power Transmission System with Intrinsic

Apr 1, 2015 · A wind turbine transmission system is described wherein mechanical power directly from the slow rotation of the shaft of a large wind turbine rotor is carried over to electrical

Study on the application of energy storage system in offshore wind

Feb 15, 2016 · Abstract A novel offshore wind turbine comprising fluid power transmission and energy storage system is proposed. In this wind turbine, the conventional mechanical

Hydraulic Wind Turbine Systems | Nature Research Intelligence

Jun 11, 2025 · Hydraulic wind turbine systems represent a novel approach to wind energy conversion that replaces conventional gearbox-based drivetrains with hydraulic transmissions.

Various power transmission strategies in wind

May 8, 2019 · Currently, hydraulic power system has drawn an attention as a power transmission system in the wind turbine field. It provides some

Hydraulics in wind turbine

The hydraulic break system is based on a hydraulic system that allows controlled revolutions in all weather conditions. UFI Hydraulics product range include

Various power transmission strategies in wind

Sep 1, 2019 · A wind power system integrates different engineering domains, i.e. aerodynamic, mechanical, hydraulic and electrical. The power transmission

A novel hydraulic transmission solution to large offshore wind turbine

Jul 1, 2022 · As a comparative solution to gearbox transmission, the hydrostatic transmission has potential to improve offshore wind turbine reliability. However, d

Design and control of the mechanical-hydraulic hybrid transmission

May 1, 2024 · The torque fluctuation inside the drive chain is aggravated, which leads to the premature failure of the wind turbines. To improve the transmission stability of wind turbines,

FME-17003-CM 312.

May 17, 2018 · Figure 10 shows the principle underlying the hydraulic wind turbine using a xed-quantity pump and variable fi hydraulic motor volume timing circuit as the main transmission

Maximum Power Generation Control of a Hybrid Wind

Sep 11, 2020 · hybrid wind turbine transmis-sion system that seamlessly integrates planetary/parallel gear sets with a hydraulic transmission to improve the turbine''s reliability and

Hydraulic Wind Turbine Systems | Nature Research Intelligence

Jul 16, 2025 · Hydraulic wind turbine systems represent a novel approach to wind energy conversion that replaces conventional gearbox-based drivetrains with hydraulic transmissions.

Numerical Simulation of a Wind Turbine with a

Sep 17, 2014 · This paper describes numerical modeling and analysis of wind turbines with high-pressure hydraulic transmission machinery. A dynamic

The Simulation Research of Hydraulic System Test Platform of 1.5MW Wind

Apr 17, 2022 · The transmission chain of wind turbine is the key component of the unit to bear various loads of the wind. Its working characteristics are the important basis for testing the

Bivariate active power control of energy storage hydraulic wind turbine

Nov 15, 2022 · With the increasing proportion of wind turbines in power system, high-precision control of power generation directly affects the proportion of wind turbines connected to the

Hydraulic Wind Power Transfer System Modeling

Jul 25, 2024 · The hydraulic wind power transfer system consists of a fixed displacement pump driven by the prime mover (wind turbine) and one or more fixed displacement hydraulic motors.

Chap Drive 2 | PDF

This document discusses ChapDrive, a company established in 2006 that is developing a hydraulic transmission system for wind turbines as an alternative

How Are Hydraulics Used in Wind Turbines?

May 19, 2025 · A key application of hydraulics in wind energy is in hydraulic wind turbines, which utilize a hydraulic transmission system. This approach offers a significant alternative to

Maximum Power Generation Control of a Hybrid Wind

Sep 11, 2020 · Xiuxing Yin, Xin Tong, Xiaowei Zhao, and Aris Karcanias Abstract—Thispaperpresentsthedesign,modeling,andoptimal power generation control of a

Research on a power smoothing control strategy for energy

Dec 26, 2022 · To solve the problem of large output power fluctuations in wind turbines and improve grid adaptability, a hydraulic energy storage system is introduced in traditional

Energy hydraulic transmission system of wind turbine

Apr 8, 2014 · Abstract: The principles of hydraulic transmission were analyzed by illustrating off-grid wind turbine and on-grid wind turbine. A method to realize variable speed constant

Study on speed and torque control of a novel

Apr 23, 2019 · A wind turbine is the most typical machine used to capture energy from the wind. The system design goal of a wind turbine is to obtain as much

Review of fluid and control technology of hydraulic wind turbines

May 4, 2017 · This study examines the development of the fluid and control technology of hydraulic wind turbines. The current state of hydraulic wind turbines as a new technology is

Simulation of a novel wind–wave hybrid power generation system

Jan 1, 2022 · The mutual compensation of offshore wind energy and wave energy provides a cost-effective solution to offshore power supply. Herein, a novel wind–wave hybrid power

6 FAQs about [Hydraulic transmission system of wind turbine]

Which transmission system is used in wind turbine?

Normally, the mechanical transmission system (gear train) is used to transmit the power in wind turbine. But this transmission is not suitable in large scale power production. Currently, hydraulic power system has drawn an attention as a power transmission system in the wind turbine field.

What is power transmission in a wind turbine rotor?

The power transmission from the turbine rotor to the generator is an important and integral part of the wind turbine system. Generally, the power transmission unit is of two types, e.g., mechanical transmission system and hydrostatic power transmission system (HST).

How hydraulic technology is applied in wind energy?

With the development of hydraulic components and the growing size of wind power generation, hydraulic technology has gradually been applied in wind energy, such as the hydraulic pitch system 2 listed in Table 1, the hydraulic braking system, 3 and hydraulic transmission system 4, 5 depicted in Table 2.

What is a wind turbine with power hydraulic system?

Wind turbine with power hydraulic system In Fig. 6, the hydraulic power transmission unit is composed by an accumulator, control valve, nozzle and a priority flow divider valve to attain a stable power output from the offshore wind turbine as the input wind velocity is unstable (refer Fig. 7).

Does hydraulic power transmission work for variable speed wind turbines?

Laguna et al. had presented a closed-loop hydraulic power transmission (contained hydraulic pump, hydraulic motor, water pump and nozzle) for variable speed wind turbine. The results were compared with reference gear train transmission to analyze the dynamic performance in terms of fluctuation of power and torque.

Why is hydraulic transmission important for wind power generation?

With the development of large-scale wind power generation and offshore wind energy, reducing the nacelle weight and the gear failure rate is increasingly important. Hydraulic transmission is characterized by its flexible layout and transmits large energy with small volume and weight, which suits the demands of wind power generation.

Industry Information

- Thimphu outdoor mobile power box

- Norway new energy storage equipment

- PV inverter rated AC voltage

- Riyadh What is an energy storage equipment company

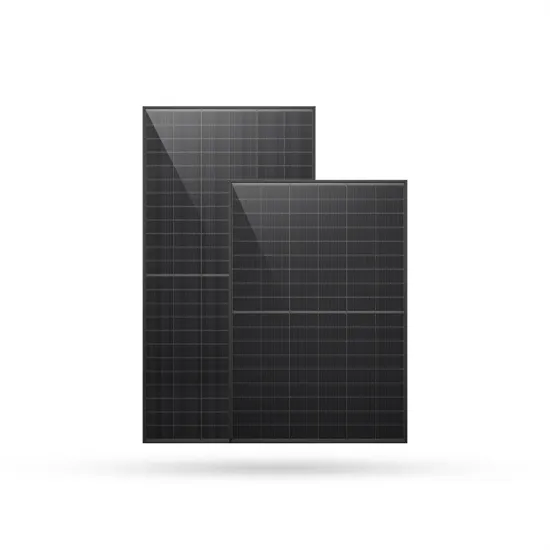

- Sukhumi crystalline silicon photovoltaic module glass

- 20kw energy storage lithium battery

- Completed new energy storage projects

- Rankings of photovoltaic and energy storage

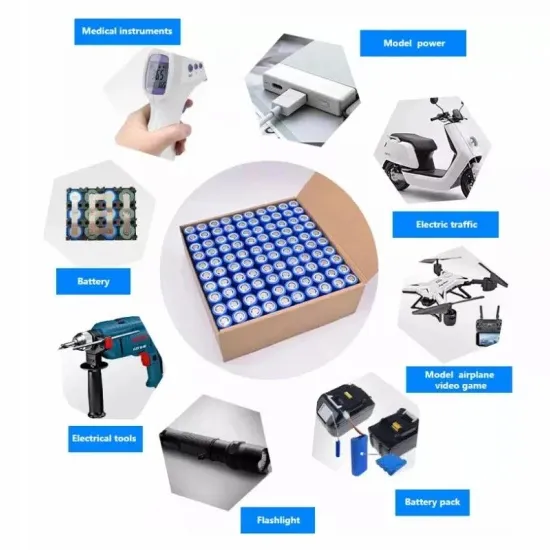

- Characteristics of electrochemical energy storage fuel cells

- Kyrgyzstan 36kw inverter

- Is the life of Honduras lithium battery pack short

- Andor Energy Storage Battery Liquid Cooling Solution

- Columbia supercapacitor module price

- Which brand of Vienna 15kw energy storage has good performance

- 12V quality brand inverter

- Prices of energy storage products in Papua New Guinea

- Vientiane outdoor communication battery cabinet replacement price

- Paraguay photovoltaic panel manufacturer

- Sodium pyroantimonate for photovoltaic glass

- How heavy is a solar inverter

- Norwegian rack-mounted energy storage battery company

- Ecuadorian energy storage vehicle equipment manufacturer

- China s first island power base station

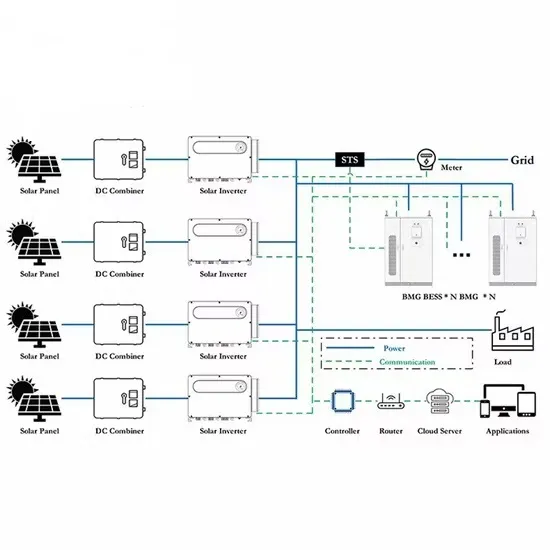

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.