Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

A review on silicon photovoltaic module degradations and

Mar 1, 2025 · Photovoltaic (PV) systems have been deployed at an unprecedented rate due to the growing worldwide demand for clean energy. Nevertheless, the most significant challenge is

Oxidation Impact of CIGS Photovoltaic Modules Performance

Sep 10, 2021 · Visual Inspection, Junction Box Analysis, Thermographic Analysis, I-V and P-V curves in Real Conditions, Energy Test, Maximum Power Determination and

Photovoltaic panel line oxidation

Photovoltaic panel line oxidation How does oxidation affect a PV module? The oxidation process has been accentuated over the last 10 years,cells show two concentric squares,the inside one

Corrosion testing of solar cells: Wear-out degradation behavior

Dec 1, 2022 · In this work, an accelerated aging test for acetic acid corrosion was developed to probe wear-out and end-of-life behavior and facilitate screening of new cell, passivation,

Different Degradation Modes of PV Modules: An Overview

Sep 17, 2022 · The technological advancements and lower energy costs have provided a smooth pathway for solar photovoltaic (PV) technology to grow as one of the leading renewable

Oxidation: A dominant source for reduced

PDF | On Feb 1, 2020, Tarana Afrin Chandel and others published Oxidation: A dominant source for reduced efficiency of silicon solar photovoltaic modules |

Accelerated degradation of PET-based photovoltaic

Oct 24, 2024 · Correlation between mechanical and chemical degradation after outdoor and accelerated laboratory aging for multilayer photovoltaic backsheets, Reliability of Photovoltaic

Simultaneous Halides Oxidation Inhibition and Defects

Apr 22, 2025 · Despite significant progress in improving the photovoltaic efficiency of perovskite solar cells (PSCs), achieving long-term operational stability remains challenging for their

An improved and comprehensive mathematical model for solar photovoltaic

May 5, 2019 · This paper presents an improved and comprehensive mathematical model for photovoltaic (PV) device, developed in Matlab based on the basic circuit equation of a solar

the solarblogger: PV Cell Formats and Size Guide

Mar 5, 2021 · Here''s a handy diagram I created to help show the difference between all the new solar PV cell formats in the market right now.

Solar Cells and Modules

Polycrystalline Silicon Photovoltaic (PV) Cells Polycrystalline or multi crystalline silicon PV cells are made from cast square ingots — large blocks of molten

Degradation analysis of photovoltaic modules after

Sep 6, 2024 · The analysis of degradation mechanisms of photovoltaic (PV) modules is key to ensure its current lifetime and the economic feasibility of PV systems. Field operation is the

Review of c-Si PV module recycling and

Jan 21, 2025 · Abstract As solar energy emerges as a pivotal renewable energy source, the environmental challenge of end-of-life photovoltaic (PV) module

UV LED ageing of polymers for PV cell encapsulation

Aug 14, 2024 · PV modules are generally made of front and back protection layers that surround two polymer sheets that encapsulate PV cells.

Eco-friendly recovery and preparation of high purity nano

Jun 22, 2025 · With the increasing deployment of photovoltaic modules, recycling of waste photovoltaic has become a topic of great concern. Silver (Ag) represents a significant resource

Review of degradation and failure phenomena in

2 days ago · Whilst the most common technology today is mono- and multi-crystalline silicon, this article aims to give a generic summary which is relevant for a wider range of photovoltaic

photovoltaic cells – solar cells, working principle,

The article explains photovoltaic cells of different generations and material systems, their working principles and many technical details.

Degradation of materials in PV modules

Nov 22, 2019 · Role of material degradation in PV module reliability Encapsulation materials play an important role in PV module reliability − Most prominent PV module failure mechanisms are

Assessment of Photovoltaic Module Failures in

Furthermore, it accelerates the oxidation process of EVA itself. Also, the type of backsheet used in the PV module influences many degradation mechanisms

Lifetime Evaluation of Photovoltaic Polymeric

Dec 3, 2022 · Photovoltaic (PV) power generation plays a significant role with the increase of installed capacity of renewable energy. The effects of

Perovskite solar modules with high efficiency exceeding

Aug 1, 2025 · Despite lab-scale efficiencies surpassing 27% in perovskite solar cells, scaling up to large-area perovskite solar modules (PSMs) for commercial use remains challenging. Key

Damp‐heat induced degradation in photovoltaic

Mar 11, 2022 · Single-cell mini-modules were aged under DH conditions. Their performance was compared with half-encapsulated PV cells, either front or

The degradation of multi-crystalline silicon solar cells after

Sep 1, 2014 · Lower performance of multi-crystalline silicon solar cells is usually observed after long-term damp heat test at 85 °C/85% relative humidity. Performance degradation is known

Potential measurement techniques for photovoltaic module

Nov 1, 2021 · Cell-cracks (23%) and hotspots (18%) are the most reported sources of PV module defects. The reviewed publications provide strong support for the claims that the I–V curve

Degradation analysis of photovoltaic modules after operating for

Jul 1, 2021 · A thorough understanding of PV module degradation mechanisms and field operation rates are required to promote this market expansion. Degradation of PV modules leads to

Durable polyolefin encapsulants in aged photovoltaic modules

Oct 1, 2022 · The long-term durability of photovoltaic (PV) modules is an increasingly important issue in terms of the total power output of PV systems that have recently been adopted

DuraMAT May 2020 Webinar Backsheet Materials for PV

Mar 6, 2023 · Water spray (front and back) Mechanical loading System voltage bias (±1500 V) Variable load resistors 6x 4-cell mini-module 8x single-cell modules Multiple coupons

Chemical treatment of crystalline silicon solar cells as a

Sep 28, 2023 · Photovoltaic modules in crystalline silicon solar cells are made from the following elements, in order of mass: glass, aluminium frame, EVA copolymer transparent hermetising

Interpreting accelerated tests on perovskite

May 15, 2024 · Metal halide perovskite solar cells exhibit impressive power conversion efficiencies and are deposited by a variety of techniques, which

Degradation and Failure Modes in New

This detailed analysis by Task 13, provides essential insights into the reliability and performance of cutting-edge photovoltaic technologies, focusing on the

Glossary of Photovoltaic Terms

photovoltaic (PV) cell --The smallest semiconductor element within a PV module to perform the immediate conversion of light into electrical energy (dc voltage

Oxidation: A dominant source for reduced efficiency of

Jan 1, 2020 · Degradation of solar cells may be (i) early degradation and (ii) long-term degradation [18]. Early degradation of module is due to change in the design of the solar

UV-induced degradation of high-efficiency silicon PV

Dec 9, 2022 · After years of improvement in photovoltaic (PV) module performance, including the reduction of power degradation rates toward a mean of 0.5% year to 0.6% year 1 for crystalline

Assessment of Photovoltaic Module Failures in the Field

Apr 15, 2020 · They found that even PV modules with uncured EVA are not likely to creep signifi-cantly in most environments and mounting configurations, partially due to post-crosslinking of

Assessment of Photovoltaic Module Failures in the Field

Aug 19, 2025 · The mission of the IEA PVPS Technology Collaboration Programme is: To enhance the internation-al collaborative efforts which facilitate the role of photovoltaic solar

6 FAQs about [Square Oxidation of Photovoltaic Module Cells]

How does oxidation affect a solar module?

According to IEA-PVPS TASK13-01 (2014) and (Jahn et al., 2018), in the initial period of operation, , antireflecting (AR) layer degradation and cracked cell in turn, mainly affects the degradation rate of the nominal power during its mid-life period, reducing the of the modules. Oxidation affects significantly the module during last years of life.

What factors affect the degradation of PV modules?

Degradation of PV modules is highly dependent on the climate (Mussard and Amara, 2018) but also depends on lamination materials, solar , aggressive environmental parameters, PV technology, period of exposition, the installation method, , solar radiation concentration mechanism and PV system voltage.

What happens if a PV module is degraded?

Degradation of PV modules leads to results in generation of various types of defects in the frame, junction box, front and back side of the PV module.

What is the degradation rate of 90 m-c-Si PV modules?

Pramod et al. (2016) reported that after 22 years outdoor exposure of 90 m-C-Si technology PV modules with nominal power 40 Wp in a composite climate of India that the degradation rate of the peak power has been an average value 1,9%/year.

Can perovskite solar cells achieve long-term operational stability?

Learn more. Despite significant progress in improving the photovoltaic efficiency of perovskite solar cells (PSCs), achieving long-term operational stability remains challenging for their commercialization. Light-induced halide ion migration causes instability, oxidizing iodide into iodine.

Can a real-time degradation test predict a specific PV module failure?

Those tests do not have the ability to reproduce all degradation modes observed in real-time field exposure (Jorgensen et al., 2003) nor to predict the degradation of a specific PV module failure what remains a challenging task (Köntges et al., 2017).

Industry Information

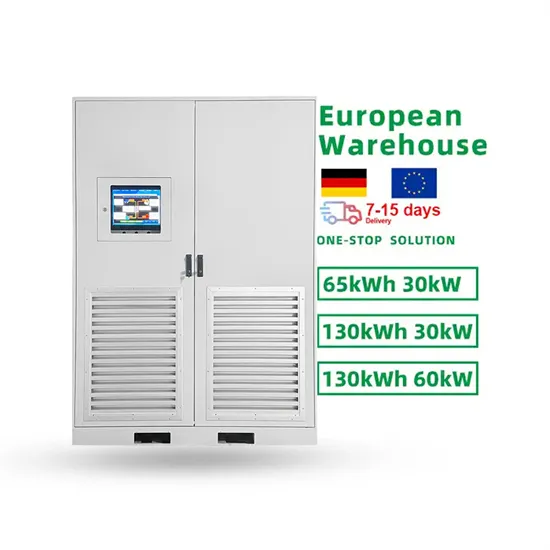

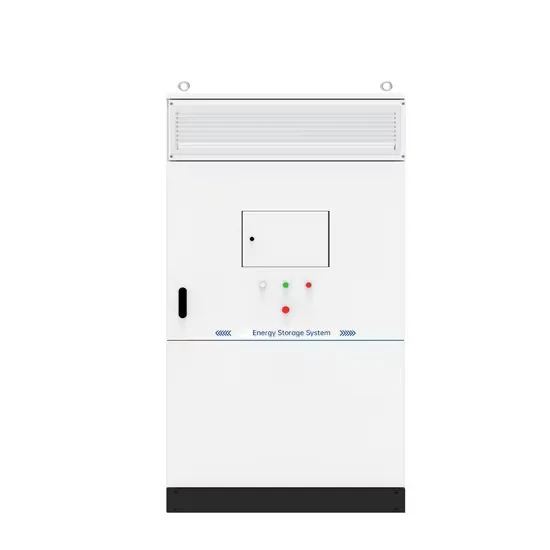

- Distributed energy storage power station export

- Wholesale 30kw solar inverter in Ecuador

- Conventional photovoltaic panel power generation

- Battery cabinet and battery cell prices

- Communication base station solar energy manufacturers China

- Oslo inverter recommended manufacturers

- Mechanical energy storage battery

- Gabon brand new container wholesale

- Cheap omega solar inverter for sale Seller

- Battery cabinet a-8

- Yerevan portable power bank manufacturer

- Photovoltaic energy storage prices are low

- Smart foldable photovoltaic panel price

- Middle East lithium battery bms structure company

- Somalia UPS uninterruptible power supply specifications and dimensions

- Main circuit breaker for sale in Finland

- Heterostructure photovoltaic glass

- 5g indoor solar base station

- Myanmar Lighting Solar Lights

- Wholesale rv circuit breaker in Ecuador

- Somalian construction site photovoltaic folding container wholesale

- Composition of power battery pack

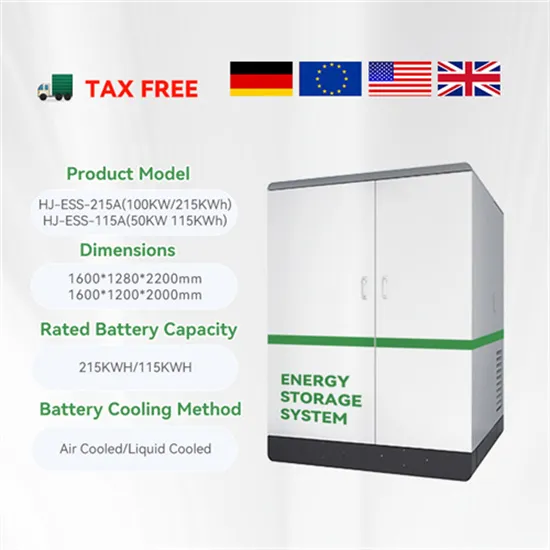

- Buenos Aires EK energy storage cabinet cost

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.