Power battery structure and core components

In summary, the composition of power batteries involves multiple aspects such as battery cells, battery modules and battery packs, battery management

Battery Composition and Cell Formats: From

Jun 18, 2024 · The three most common cathode compositions in electric vehicles are Nickel Manganese Cobalt Oxide (NMC), Lithium Iron Phosphate (LFP),

锂电池单体(cell)、电池组(Batteries)和电池包(pack

Jun 27, 2018 · 没有接触过锂电池的很多朋友,一般会把电池厂家生产好了的电池包(pack)当成是一块大电池,实际上,我们用的锂电池其实也跟铅酸电池一样,也是由一块一块的单体电池

Explore Pack Battery: Composition, Characteristics and

Driven by modern technology and mobile devices, batteries have become an essential source of energy in our lives. In the battery field, Pack battery, as an important form, has a wide range of

Composition of marine power battery packs

Jul 4, 2024 · Marine power battery packs consist of multiple battery packs, with lithium batteries commonly used as battery packs. Lithium batteries have advantages such as high energy

A Guide to Understanding Battery Specifications

Dec 18, 2008 · A battery is a device that converts chemical energy into electrical energy and vice versa. This summary provides an introduction to the terminology used to describe, classify,

Understanding the Composition of Batteries and Battery Packs

Jun 6, 2025 · Battery Pack Composition In applications requiring higher power, such as EVs, individual battery cells are assembled into modules, which are then combined into a battery

The composition, method and parameter

Nov 13, 2023 · The lithium-ion battery PACK technology is an essential component in the energy storage industry. Let''s explore some fundamental

Composition, Method, and Parameter Analysis of Lithium

Aug 11, 2024 · Lithium-ion battery PACK technology plays an important role in the energy storage industry. It involves connecting multiple lithium-ion individual battery cells in series and parallel

The Architecture of Battery Energy Storage

Sep 23, 2020 · Before discussing battery energy storage system (BESS) architecture and battery types, we must first focus on the most common

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Composition Of Battery Pack Material

May 17, 2025 · This article explores the internal structure of a battery pack, its component parts and looking at the several battery pack material used in

Power Battery Basics: Cells, Modules & Packs

Jan 4, 2024 · Today, we''ll explore the three most crucial elements: cells, battery modules, and battery packs. 1. Cells: The Building Blocks. Cells serve as the

Analysis of the composition of the power lithium-ion battery PACK

As we all know, the battery PACK is the core energy source of new energy vehicles, which supplies the driving power for the whole vehicle. It mainly forms the main body of the battery

Understanding the Components of a Battery Pack

Jun 9, 2025 · Explore the key components and advanced technologies of lithium-ion battery cells, focusing on anode materials, cathode performance,

What is lithium ion power pack and its

Aug 10, 2025 · As the core component of lithium ion power pack, batteries are currently classified into three main categories according to the shape of the

The connection composition of the battery pack

The rated voltage of a single battery is usually 2V, so to form the rated voltage of a battery pack for actual use (such as 24V, 48V, etc.), it must be composed of multiple single batteries

The structure and core components of power

Oct 15, 2024 · In summary, the composition of power batteries involves multiple aspects such as battery cells, battery modules and battery packs, battery

Li-ion battery materials: present and future

Jun 1, 2015 · Li-ion batteries have an unmatchable combination of high energy and power density, making it the technology of choice for portable electronics, power tools, and hybrid/full electric

Power battery structure and core components

The battery pack is a combination of multiple battery modules connected in series, and is the power battery assembly of electric vehicles. The battery

Composition of the Battery Pack | ESSCOLLEGE

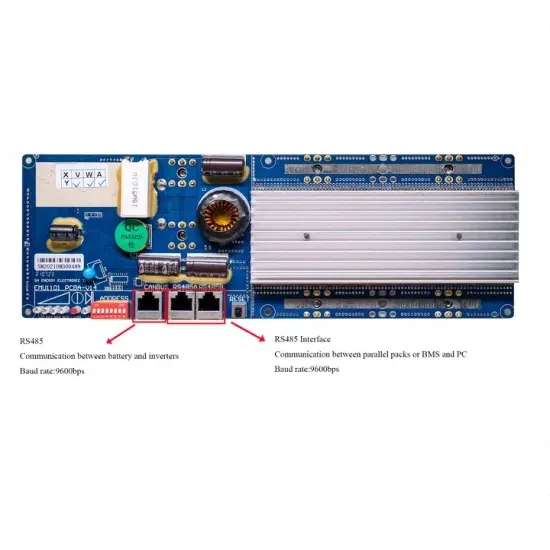

The lithium-ion energy storage battery pack consists of a battery unit, a management system, a thermal management system, a safety protection system, a connecting component and a

Battery Chemistry Explained: Cell Types in

May 22, 2025 · Their battery packs and cells have been installed in more than 2,500 vehicles while collectively covering more than 100 million miles

Rechargeable Lithium-Ion Batteries

Jul 1, 2024 · Lithium-ion batteries are the most commonly used rechargeable batteries in today''s electronic devices. Understanding the composition and

Battery Composition and Cell Formats: From

Jun 18, 2024 · As battery technology progresses to address modern applications'' diverse and expanding demands, the focus intensifies on optimizing battery

Explore Pack Battery: Composition, Characteristics and

In the battery field, Pack battery, as an important form, has a wide range of applications. This article will deeply explore the composition, characteristics and application of Pack battery to

Function and components of battery pack

Introduction Lithium-ion battery packs for electric vehicles have large battery capacity, many series and parallel connections, complex systems, and high

Battery pack and battery cell mass composition,

Jul 20, 2025 · Thus, Figures 7 and 8 show the results obtained from assessing a battery pack of NMC 811 and LFP, respectively, and also comparing the

Sturcture of Battery: From Cell to Module and

Apr 21, 2025 · While batteries are designed to facilitate effectively their maintenance, repairing and optimizing the process of power sourcing and

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · A battery pack is essentially a collection of batteries designed to power various devices and applications. These packs are more than just a

A study on parameter variation effects on battery packs for

Oct 1, 2017 · A set of parameters are introduced to study the cell variation and their impacts on battery packs are analyzed through the battery pack capacity loss simulation and experiments.

Understanding Battery Types, Components and

May 30, 2024 · Batteries have become an integral part of our everyday lives. In this article, we will consider the main types of batteries, battery components

[电池扫盲]一文带小白了解电芯(cell),电池模块

Jun 18, 2023 · 电池包 将多个电池模块进行串并联,再加上用来管理电池温度或电压等的 电池管理系统 (BMS, Battery Management System)和冷却设备等,就

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

A systematic comparison of the packing density of battery cell-to-pack

Mar 1, 2022 · This microarticle shows the potential of battery cell-to-pack design approaches by means of a systematic investigation at different depths of implemen

Power Tool Batteries: A Comprehensive Guide —

Nov 18, 2024 · Power tool batteries have come a long way from bulky nickel-cadmium (NiCd) packs. Today, lithium-ion (Li-ion) technology dominates the

6 FAQs about [Composition of power battery pack]

What is battery lithium ion power pack?

The battery lithium ion power pack is thecore energy source of new energy vehicles, providing driving power for the whole vehicle. As the core component of new energy vehicles, its quality directly determines the performance of the whole vehicle.

What is the structure of a battery?

While batteries are designed to facilitate effectively their maintenance, repairing and optimizing the process of power sourcing and sinking, their structural composition follows a certain level starts from cells to modules and packs.

What are the components of a battery cell?

To review its structure more specifically, a battery cell can be further disassembled into the following components: Anode (Negative Electrode): Anode is typical made of lithium or graphite to facilitate the storage and releases of energy.

What is the difference between battery cell and battery lithium ion power pack?

Battery cell: the most basic element that constitutes the battery lithium ion power pack and battery lithium ion power pack, generally the voltage that can be provided is between 3v-4v; Battery lithium ion batteries: a collection of multiple monomers to form a single physical module, providing higher voltage and capacity.

What are the basic elements of a battery?

The fundamental elements of a battery are battery cells, the production of which has more to do with chemicals and processing now that they are the basic unit where electrical energy is supposed to be stored as much as possible. To review its structure more specifically, a battery cell can be further disassembled into the following components:

What are the different types of lithium ion power packs?

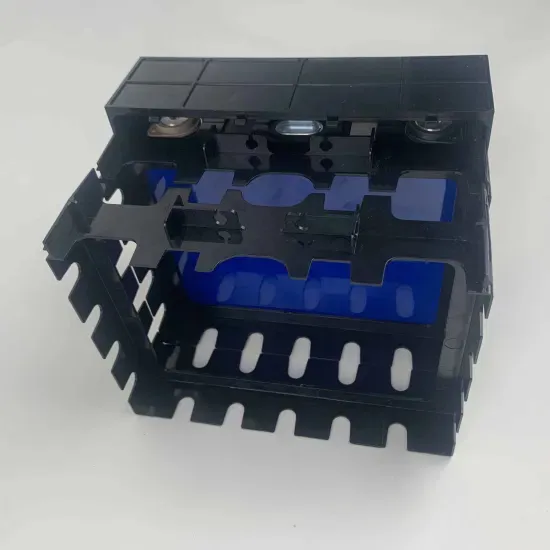

As the core component of lithium ion power pack, batteries are currently classified into three main categories according to the shape of the batteries:prismatic shells, cylinders, and soft lithium ion power packs (polymer batteries). The positive and negative electrodes are encapsulated into corresponding casings in different ways.

Industry Information

- High quality new circuit breaker for sale Wholesaler

- Communication base station inverter grid connection and signal

- Standards for wind power size of communication base stations

- Notification of the completion of Nordic energy storage project

- Cheap blown circuit breaker factory producer

- How much does the Bridgetown power inverter cost

- Advantages and disadvantages of energy storage pcs system

- Brand high power portable power bank

- Praia power frequency isolation 250kw inverter

- Wholesale 1600 amp switchgear in Oman

- Container outdoor power supply 2000W

- Energy storage container push-pull structure

- Solar panels plus on-site energy

- Ulaanbaatar Solar Power System Installation

- Baghdad 40-foot energy storage container factory

- Mobile power box modification

- DC screen battery cabinet price in East Africa

- Nassau Industrial Energy Storage Manufacturer Supply

- UPS battery cabinet a32 size

- How much does a super battery cabinet cost

- Asmara Independent Energy Storage Power Station

- Lima PV grid-connected inverter

- Kuwait mining UPS uninterruptible power supply price

Commercial & Industrial Solar Storage Market Growth

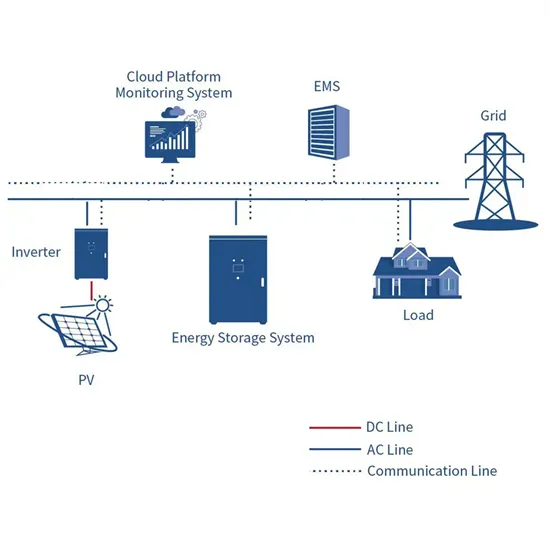

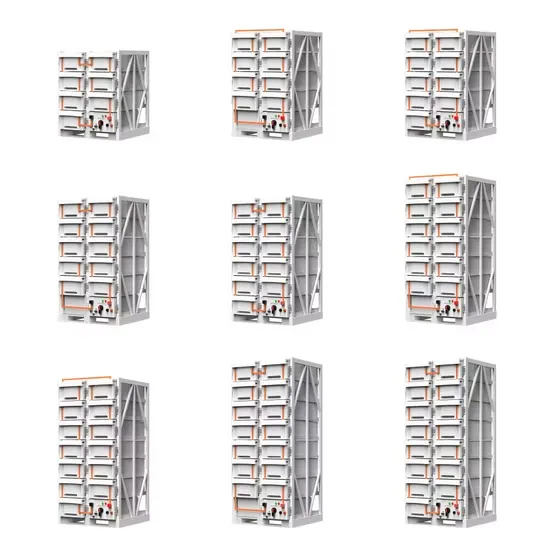

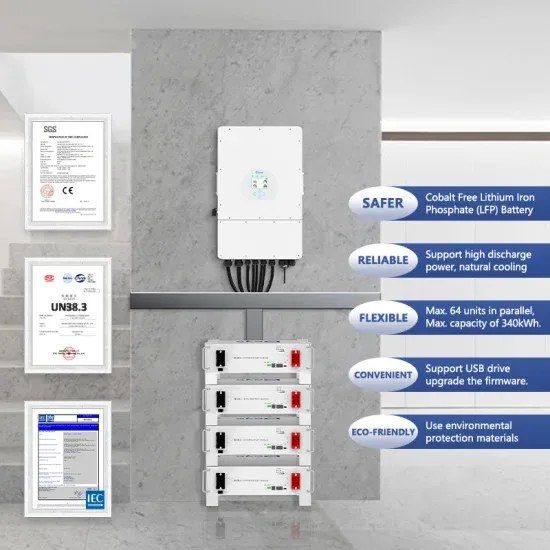

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

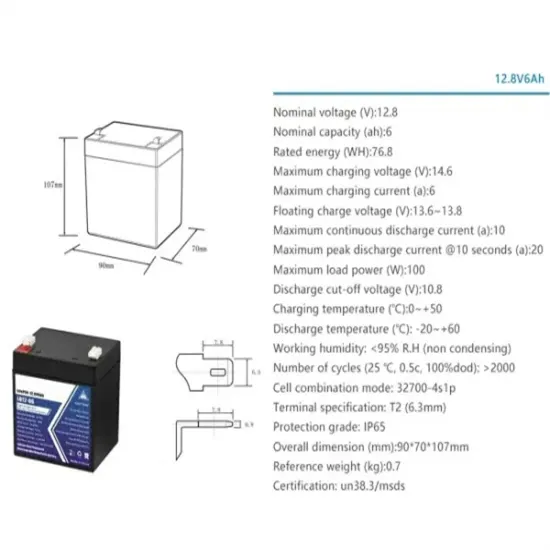

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.