Thin Film Photovoltaics

Jan 1, 2018 · Thin film solar cell technology has recently seen some radical advancement as a result of new materials and innovations in device structures. The increase in the efficiency of

energy photovoltaic

8YF330 REVAMPING SOLAR INVERTER EEI 8YF330 is a double stage inverter designed to perfectly adapt to a very wide range of voltages on the

Technical Note

Sep 11, 2020 · Introduction Crystalline modules and thin-film modules differ in structure: crystalline modules typically consist of individual square cells (Figure 1), while thin-film modules are

Lifetime testing of metallized thin film capacitors

Jun 1, 2013 · In order to understand the degradation mechanisms and failure precursors of metallized thin film capacitors (MTFC) used in photovoltaic (PV)

Review of state-of-the-art: Inverter-to-array power ratio for thin

Jul 1, 2017 · In this paper, the state-of-the-art is presented to collect a relevant information related to the sizing ratio around the globe as well as introduces a new concept of inverter sizing

PV Inverter | Thin Film Resistor Manufacturer

Firstohm is one of the few companies who is able to design thin-film MELF resistors according to customer''s requirements with high quality and reliability.

Lifetime Testing of Metallized Thin Film Capacitors for

Abstract — In order to understand the degradation mechanisms and failure precursors of metallized thin film capacitors (MTFC) used in photovoltaic (PV) inverters, we have carried out

A Comprehensive Review of Solar Photovoltaic Systems:

Apr 7, 2025 · This article offers a detailed analysis of solar photovoltaic (PV) technology. It examines the distinct qualities and developments of the three generations of solar PV

A multi-string photovoltaic inverter for thin-film or back-side

Abstract Photovoltaic inverters are widely used to feed solar generated power into the public grid. Inverter topologies have to be carefully chosen, depending on the type and on the power of

Technical Note

Sep 11, 2020 · Thin-film modules are particularly popular in BIPV – Building Integrated PV. They are often preferred due to their uniform appearance, and additionally these installations are far

Thin Film vs. Crystalline Silicon PV Modules

4 days ago · There is a competitive price advantage of Thin Film modules over Crystalline Silicon PV modules. Despite the fact that the global thin film

Environmental effects on a grid connected 900 W photovoltaic thin-film

Oct 1, 2011 · 3. Test bed photovoltaic system The system, installed on the rooftop of the Arzanah building at the Petroleum Institute in Abu Dhabi, is composed of a 900 W thin-film a-Si, PV

Photovoltaic inverter and thin film modules

One of the most important applications for thin-film solar technology,specifically Copper Indium Gallium Selenide (CIGS) and Gallium Arsenide (GaAs) technology is the space applications.

Products

METEKTRON is a lightweight, universal, retrofit solar PV system designed for industrial and commercial buildings that cannot support the weight of a

Photovoltaic micro-inverter with active filtering and thin-film

Nov 22, 2017 · This work proposes the application of an active filtering method to compensate the dc-link low frequency voltage ripple of a 250 W two-stage PV micro-inverter.

英国求购太阳能光伏 (Solar photovoltaic)

Component: crystalline silicon or thin film solar panel Inverter: Photovoltaic grid-connected inverter Bracket: 1 set (design drawings according to actual size) Confluence box: 1 set

Thin Film Solar Panels: The Green Energy

What are Thin Film Solar Panels? Thin film solar panels represent a breakthrough in photovoltaic technology, offering a departure from conventional crystalline

Review of state-of-the-art: Inverter-to-array power ratio for thin

Jul 1, 2017 · Numerous sizing methodology for the combination of inverter and PV array components have appeared in the literature including guidelines and third-par

PV Inverter | Thin Film Resistor Manufacturer | FI

4 days ago · PV Inverter Solar Inverter PV inverters are critical energy conversion devices designed to convert the unstable direct current (DC) voltage generated by solar panels into a

Module Technology

Feb 4, 2025 · Contents Alongside PV modules of crystallized silicium, new cell technologies and advancements of conventional PV modules are continually surging onto the market. At the

Thin-Film Photovoltaics: Emerging and Established Solar

Apr 25, 2025 · The report extensively covers the entire thin film PV market technologies, including dye-sensitized solar cells (DSSC), organic photovoltaics (OPV), perovskite PV, cadmium

Lifetime Testing of Metallized Thin Film Capacitors for

Jan 16, 2024 · Abstract — In order to understand the degradation mechanisms and failure precursors of metallized thin film capacitors (MTFC) used in photovoltaic (PV) inverters, we

MgZnO High Voltage Thin Film Transistors on

Oct 10, 2016 · We demonstrate a Magnesium Zinc Oxide (MZO) based high voltage thin film transistor (HVTFT) built on a transparent glass substrate.

MgZnO High Voltage Thin Film Transistors on

Oct 10, 2016 · We demonstrate a Magnesium Zinc Oxide (MZO) based high voltage thin film transistor (HVTFT) built on a transparent glass substrate. The

Photovoltaics, Including New Technologies (Thin Film) and a

Jan 1, 2020 · In brief, the principle of PV cells and modules is explained. Furthermore, the most important technologies of production of both crystalline silicon and thin-film modules and

Inverse Design of High Absorption Thin‐Film

Aug 27, 2012 · The "spectroscopic limited maximum efficiency" metric is applied to identify materials design principles leading to high absorption for application

Thin-Film Photovoltaic Market Size, Share

The global Thin-Film Photovoltaic Market size in terms of revenue was estimated to be worth $6.2 billion in 2024 and is poised to reach $12.4 billion by 2029,

A transformerless single-phase PV inverter circuit for thin-film

Oct 29, 2014 · This paper deals with a new transformerless single-phase photovoltaic inverter circuit. The circuit is well suited for thin-film or back-side contacted solar modules because one

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Thin-film solar panels are made by depositing a thin layer of photovoltaic material onto a substrate, making them lightweight and flexible.

Module Technology

Feb 4, 2025 · Due to the versatile range of different topologies, SMA inverters in combination with the optional supplementary equipment are so flexibly deployable that an optimum device is

Thin film solar power inverter

Jan 2, 2025 · Thin film solar power inverters are an integral component in the realm of renewable energy solutions, particularly in photovoltaic systems. These devices convert the variable

What are monocrystalline, polycrystalline and

Aug 25, 2014 · Basic introduction into solar panel and cell technology. Monocrystalline, polycrystalline and thin film solar panels and how to indentify

6 FAQs about [Photovoltaic thin film inverter]

What is a thin-film module – building integrated PV (BIPV)?

Thin-film modules are particularly popular in BIPV – Building Integrated PV. They are often preferred due to their uniform appearance, and additionally these installations are far more frequently affected by shading. In particular, vertical surfaces are generally affected by shading to a greater extent, e.g. by neighboring buildings and canopies.

Why do thin-film modules have a high voltage?

Due to the high number of individual cells, lower cell and module currents and higher module voltages are typical of thin-film modules. That means that relatively few modules can be connected in series. Some thin-film modules have higher voltages during their initial operation, further reducing the possible string length.

Do thin-film modules need power optimizers?

While the impact on thin-film systems is lower than the impact on systems with crystalline modules, it cannot be ignored. Using power optimizers prevents the mismatch losses and provides designers with greater flexibility. Thin-film modules often have higher current and voltage tolerances.

How insulated is a PV plant?

The most cells in a PV plant lay permanently on a non-zero potential. Since large leakage currents are to be avoided for personnel and fire protection reasons, the PV modules must be well insulated. To put it another way: the insulation resistance Riso must not exceed a certain value.

How many m2 should a PV inverter have?

2 m2 in contrast only a minimum of 20 M Ω . For PV plants without galvanic isolation (transformerless), the Riso must be at least 2 000 kΩ per kW input power of the inverter. Adherence to this limiting value must be monitored by the inverter.

Why do thin-film modules lose power over time?

Thin-film modules (as well as crystalline modules) may exhibit fault mechanisms that cause the modules to lose power over time. While crystalline modules can suffer from PID (Potential Induced Degradation), thin-film modules have irreversible mechanisms such as TCO corrosion.

Industry Information

- Nigeria container energy storage system

- Basseterre Battery Energy Storage Cabinet

- Building Solar Air Conditioning System

- Which manufacturer of photovoltaic panels is good in Ireland

- Sanaa Energy Storage Container Procurement Bidding

- Huawei Tirana Energy Storage Power Plant

- 6kw inverter for low voltage cabinet

- Estonia container size wholesale

- Lithium iron phosphate chemical energy storage power station

- Cadmium oxide thin film photovoltaic glass

- Estonian energy storage cabinet fire protection system manufacturer

- How much is the price of outdoor power supply in Maldives

- Energy Storage Connectivity Solutions

- Lithium titanate batteries are assembled into battery packs

- Lithium battery pack voltage conversion 220v

- Cheap high voltage breaker for sale exporter

- Supercapacitor Price in Manama

- Photovoltaic power inverter photovoltaic power supply

- Communication base station solar photovoltaic power plant

- Photovoltaic power storage extended warranty

- Grid-connected inverter grid power outage

- European UPS uninterruptible power supply manufacturers

- Lithium battery energy storage cycle number

Commercial & Industrial Solar Storage Market Growth

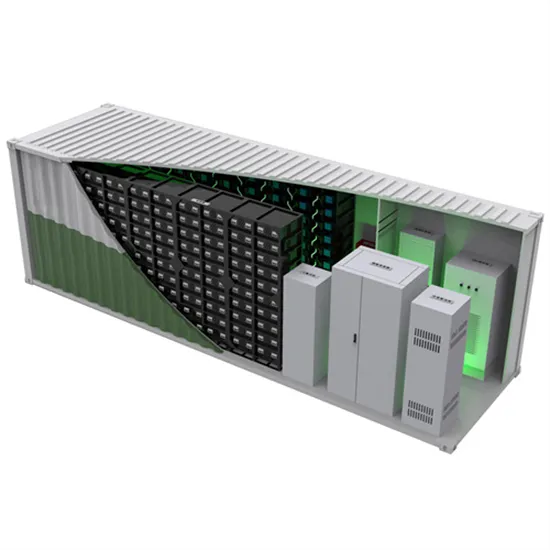

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

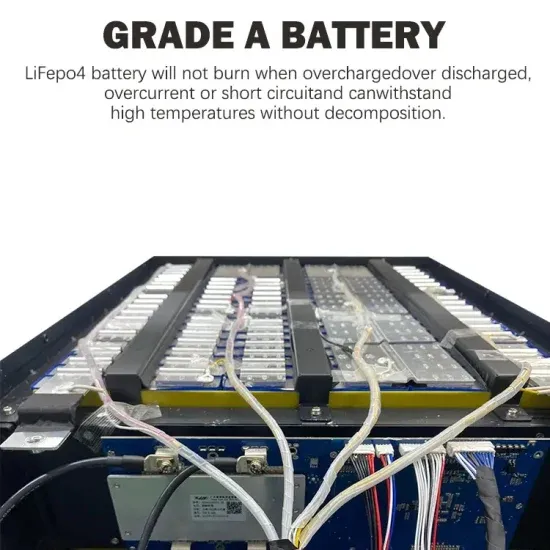

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.