Design and validate battery manufacturing

May 28, 2025 · Building a high-performing battery plant requires more than just equipment—it takes precise planning, optimized processes, and validated

Optimize Battery Assembly Line with Design and

4 days ago · Scaling your battery production for EVs and energy storage systems takes more than just equipment; it takes smart design and reliable automation.

Streamlining High-Volume Cabinet Production

Apr 26, 2006 · Streamlining High-Volume Cabinet Production Well-organized cabinetmakers share their secrets for labor time efficiency. April 26, 2006

Battery assembly solution

Aug 19, 2025 · The JOT battery assembly solution is made for high-grade battery assembly for electric vehicle, energy storage and other battery manufacturers.

Production line layout design for a battery

Jul 21, 2025 · Steps to Develop Ideal Block Layout: Founded in 1980, EFESO is a global management consultancy firm specialised in ensuring the perfect

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Automatic Prismatic lithium Battery Pack

The ACEY-XM230420 project is based on customer''s production process requirements and workshop layout, custom-made combined square shell

Design of Control System of Automated Production Line

Mar 30, 2023 · The purpose of this paper to study the production line control system is to design and optimize the automated production line control system through a deep understanding of

Battery Pack Automated Assembly Production Line

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique

Lion Energy to test lithium battery

Oct 8, 2024 · Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy storage cabinet assembly. The

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Optimal line configurations for agile production systems for battery

Jan 1, 2023 · Section 3 focuses on an approach on how to develop line configurations for a highly flexible production system for battery cells regarding different future scenarios (see Figure 1).

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

Battery Assembly Line Design, Build, and Scaling

We design and implement fully integrated battery assembly lines that streamline module and pack production, ensuring precision, consistency, and scalability.

Large and Small Cylindrical PACK Automated

Automated assembly line, cylindrical battery production, laser welding, energy storage. 2:Introduction: This production line is mainly used for the back-end

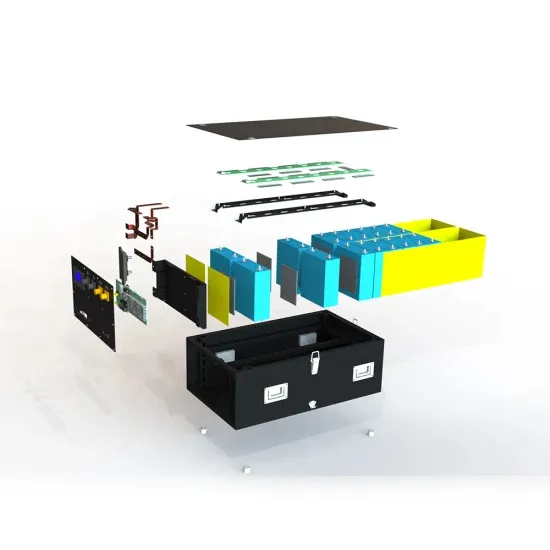

Design of cubic battery cabinet production line

in phases: production, assembly, and packaging. The pack is a complex system comprising battery packs, shunts, soft conn ctions, protective boards, outer packaging, This paper

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · BESS design IEC - 4.0 MWh system design — How should system designers lay out low-voltage power distribution and conversion for a battery energy storage system

Li-Ion battery assembly lines for energy storage

Aug 18, 2025 · BM-Rosendahl offers tailor-made assembly lines designed to streamline the production of ESS batteries. Our solutions are adaptable to

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Innovating battery assembly

Aug 13, 2025 · The battery tray assembly consists of several production steps. Depending on the battery design and manufacturing processes, manual tightening with bolt positioning and

Prismatic cell production line

Nov 1, 2024 · A prismatic cell production line is an integrated system designed for the efficient manufacturing of prismatic lithium-ion battery cells. These cells are favored in applications

Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

Prismatic Battery Pack Assembly Line

The Prismatic Battery Pack Assembly Line integrates a variety of automated equipment and technologies, mainly covering the entire process from module assembly to the final battery

Designing a Battery Pack?

Designing a battery pack ? One Place to Learn about batteries for electric vehicles: Cell Chemistry, benchmarking, Algorithms, Manufacturing.

Optimize Battery Assembly Line with Design and

4 days ago · Scaling your battery production for EVs and energy storage systems takes more than just equipment; it takes smart design and reliable automation. At Sedin Engineering, we

Battery module production | KUKA AG

The production line is divided into four main areas. In the first section the battery cells are tested and prepared for assembly. In the second plant section, a so

Automate battery production with robotics and proven

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

Industry Information

- Nigeria container energy storage system

- Basseterre Battery Energy Storage Cabinet

- Building Solar Air Conditioning System

- Which manufacturer of photovoltaic panels is good in Ireland

- Sanaa Energy Storage Container Procurement Bidding

- Huawei Tirana Energy Storage Power Plant

- 6kw inverter for low voltage cabinet

- Estonia container size wholesale

- Lithium iron phosphate chemical energy storage power station

- Cadmium oxide thin film photovoltaic glass

- Estonian energy storage cabinet fire protection system manufacturer

- How much is the price of outdoor power supply in Maldives

- Energy Storage Connectivity Solutions

- Lithium titanate batteries are assembled into battery packs

- Lithium battery pack voltage conversion 220v

- Cheap high voltage breaker for sale exporter

- Supercapacitor Price in Manama

- Photovoltaic power inverter photovoltaic power supply

- Communication base station solar photovoltaic power plant

- Photovoltaic power storage extended warranty

- Grid-connected inverter grid power outage

- European UPS uninterruptible power supply manufacturers

- Lithium battery energy storage cycle number

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.