What Are the 9 Operating Costs in Electric

Jul 24, 2025 · How Much Does It Cost To Operate An Electric Vehicle Battery Production? Setting up an electric vehicle battery production facility like

Lithium ion Battery Manufacturing Plant Cost Report

• What are the capital costs for setting up a lithium ion battery manufacturing plant? • What are the operating costs for setting up a lithium ion battery manufacturing plant? • What should be the

Lithium-Ion Battery Production Is Surging, but at What Cost?

Sep 20, 2017 · Lithium-Ion Battery Production Is Surging, but at What Cost? Gigafactories intended to scale the production of electric-vehicle batteries can exact a human toll.

Lithium-Ion Battery Manufacturing Plant: Setup

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

How much CO2 is emitted by manufacturing

Aug 8, 2025 · It depends exactly where and how the battery is made—but when it comes to clean technologies like electric cars and solar power, even the

Battery price per kwh 2025| Statista

Jun 21, 2025 · The cost of lithium-ion batteries per kWh decreased by 20 percent between 2023 and 2024. Lithium-ion battery price was about 115 U.S. dollars

Breakdown of raw materials in Tesla''s batteries

Nov 1, 2016 · It is estimated that there''s about 63 kg of lithium in a 70 kWh Tesla Model S battery pack, which weighs over 1,000 lbs (~453 kg). When asked if

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

How Much Does It Cost to Start Lithium-Ion

Apr 6, 2025 · On average, businesses can expect to spend anywhere from $100,000 to $500,000, with an average cost of around $300,000. Factors that

Lithium Battery Pack | Industrialist Wiki | Fandom

6 days ago · The Lithium Battery Pack is the final stage in Lithium production, which cannot be processed further and can be sold for $85,000. Ten Lithium

THE COST COMPONENTS OF A LITHIUM ION

Aug 17, 2025 · Cost components of a lithium-ion battery The material costs are by far the largest contributors — about 60% of the total cost. For lithium-ion

Visualized: What is the Cost of Electric Vehicle

Oct 14, 2023 · The price of an EV battery pack can be shaped by various factors such as raw material costs, production expenses, packaging complexities, and

Lithium ion battery materials?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost,

Lithium-Ion Battery Production Is Surging, but at What Cost?

Sep 20, 2017 · Though an explosion in EVs and energy storage will allow countries to rely on less carbon-intensive energy, the extraction of essential ingredients to make cost-effective lithium

Lithium Sector: Production Costs Outlook

The cost of producing concentrate at hard-rock lithium mines is generally lower than that of producing lithium chemical products from brines. In 2019, the

What Are the 9 Startup Costs for Battery Manufacturing in

Jul 24, 2025 · How Much Does It Cost To Start Battery Manufacturing For Electric Vehicles? Starting an EV battery manufacturing business, such as VoltCraft Innovations, requires careful

Why are Lithium Batteries so Expensive to

Aug 9, 2023 · While these prices are lower than back in 2008 ($1,355 kWh), lithium batteries have continually been the most expensive of battery

Electric Vehicle Battery Costs Soar

Apr 25, 2022 · Inside each electric vehicle battery pack are multiple interconnected modules made up of tens to hundreds of rechargeable Lithium

What Are the 2025 Startup Costs for Lithium Ion Battery

Jul 24, 2025 · How much does a lithium-ion battery manufacturing owner make, really? It''s a question many aspiring entrepreneurs ponder as they consider diving into this booming

Unveiling the Truth: The Real Cost to Build an

Dec 17, 2023 · Have you ever wondered how much it costs to produce an electric car battery? The rise of electric vehicles has caused a significant shift in the

FOTW #1272, January 9, 2023: Electric Vehicle

Jun 20, 2017 · The Department of Energy''s (DOE''s) Vehicle Technologies Office estimates the cost of an electric vehicle lithium-ion battery pack declined 89%

Lithium Ion Battery Manufacturing: Cost

Jul 12, 2025 · How Much Does it Cost to Operate a Lithium Ion Battery Manufacturing Business? Understanding your operating expenses is crucial

Breaking Down the Cost of an EV Battery Cell

Jan 6, 2025 · Inside each EV battery pack are multiple interconnected modules made up of tens to hundreds of rechargeable Li-ion cells. Collectively, these

How much energy is used in manufacturing a battery?

Apr 17, 2018 · Basically to manufacture a 24 kWh Lithium ion battery requires 88.9 GigaJoules, so the cost per KWh comes down to just over 1,000 kWh As the typical lifetime of a lithium-ion

What Are the 9 Operating Costs of Lithium Ion

Jul 24, 2025 · Operating a lithium ion battery manufacturing facility like PowerPulse Energy Solutions involves detailed planning around several key

Battery Manufacturing Cost Breakdown: What to Expect

Jul 12, 2025 · Raw materials like lithium, cobalt, and nickel impact the overall battery manufacturing cost. Recurring software subscriptions, insurance, and maintenance keep the

How much does it cost to make a battery cell? And how do

May 8, 2023 · How much does it cost to make a battery cell? And how do new technologies affect production costs? We teardown an industrial battery cell production line of a giga-factory in

Why Are Lithium Batteries So Expensive To

Conclusion Currently, the design and production costs of lithium batteries are higher than those of other types of chemical batteries. However, with ongoing

NMC vs LFP Costs

Dec 10, 2024 · The Q4 2023 breakdown of NMC vs LFP costs is interesting as a point in time. Here we have a comparison pulled together by P3 Group GmbH.

Optimizing Production Efficiency and Reducing

6 days ago · Overview This article is part of a series that explores the Five Key Challenges to Widespread Adoption of Electric Vehicles (EVs). In this

The Shocking Truth Behind Electric Car Battery

Dec 16, 2023 · It''s common knowledge that the future of transportation is electric, but something people rarely consider is the cost of producing the batteries that

How Much Does It Cost to Start a Lithium Ion

Mar 29, 2025 · Understanding the main factors influencing startup costs can help you budget effectively for your lithium-ion battery manufacturing venture. Be

How To Estimate The Costs To Start A Lithium

Apr 17, 2025 · Key startup costs include initial investments such as land purchase or lease, factory construction, and machinery setup. Explore What Is the True

The True Costs of Lithium Extraction: A Grim

Jan 13, 2022 · Political turbulence in Afghanistan means the cost of lithium-ion batteries will skyrocket. The Taliban now controls one of the world''s largest

EV Battery Pack Costs Were Cut By 90% From

According to the Department of Energy''s (DOE''s) Vehicle Technologies Office, the average cost of a light-duty electric vehicle''s lithium-ion battery pack

Lithium-Ion Battery Costs: Manufacturing Prices,

Mar 16, 2025 · The cost to make lithium-ion batteries ranges from $40 to $140 per kWh. Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or

How Manufacturer Can Tell You About Cost of

Jun 6, 2024 · After learning about the process of battery production and the reason for the high cost of lithium batteries, you should know each piece of

Cost Of Lithium-ion Battery Manufacturing Plant & Machinery

The Indian automobile sector is one of the most prominent sectors in the country, accounting for about 7.1% of the national GDP. The Indian Lithium-ion battery market is expected to grow at

6 FAQs about [How much does it cost to produce a lithium battery pack in Monrovia]

How to start a lithium ion battery manufacturing business?

Starting a lithium ion battery manufacturing business requires a comprehensive understanding of the costs involved. From raw materials to labor, each component contributes to the overall manufacturing expenses. It’s essential to evaluate these costs meticulously to ensure profitability and sustainability in the competitive battery market.

Is lithium ion battery manufacturing a good investment?

This surge presents an incredible opportunity for entrepreneurs looking to dive into the battery manufacturing industry. Lithium Ion Battery Manufacturing Costs can be a significant barrier to entry, but understanding these costs can set you on the right path to success.

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

What is the lithium-ion battery manufacturing plant project report 2025?

IMARC Group’s report, titled “ Lithium-Ion Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up a lithium-ion battery manufacturing plant.

Are lithium-ion batteries the future of electric vehicles?

Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even more significant cost reductions is vital to making battery electric vehicles (BEVs) widespread and competitive with internal combustion engine vehicles (ICEVs).

What is a lithium-ion battery manufacturing plant?

A lithium-ion battery manufacturing plant is a facility designed for the large-scale production of rechargeable battery cells used in various modern technologies. These plants carry out a series of precision-driven processes, including electrode preparation, cell assembly, electrolyte filling, formation, and quality testing.

Industry Information

- 12Inverter Installation

- What is energy storage system integration

- Generators for refrigerated containers

- Cyprus cylindrical lithium battery model

- Buenos Aires professional photovoltaic panel prices

- Valletta Communication Base Station Power Module Cost

- Price of zinc-iron liquid flow battery

- The whole process of energy storage battery container production

- Lead-acid colloidal energy storage battery for RV

- Cheap 5kwh hybrid inverter in China distributor

- Outdoor power supply 250wh

- Norway rack-mounted UPS uninterruptible power supply

- Huawei Azerbaijan UPS Uninterruptible Power Supply

- Can the introduction of D2D communication in cellular networks reduce the burden on base stations

- Western European photovoltaic panel manufacturers

- Inverter open loop grid connection

- Is the Basseterre all black kit suitable for the field

- Cyprus capacitor energy storage solution

- Gaborone inverter R

- Can photovoltaic inverters use batteries

- Belgian battery pack lithium battery container

- Nepal photovoltaic energy storage

- New outdoor power supply in Osaka Japan

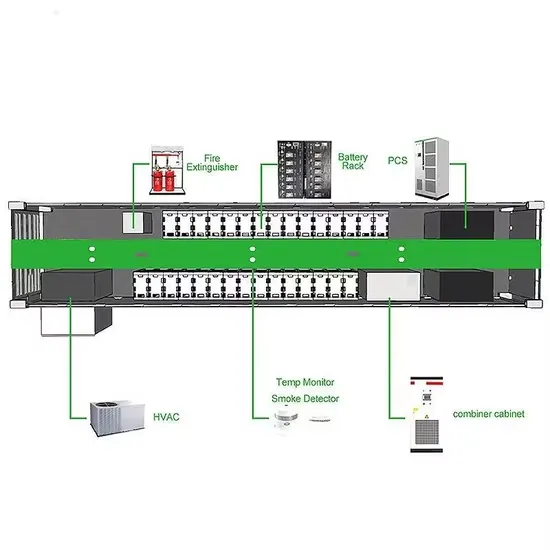

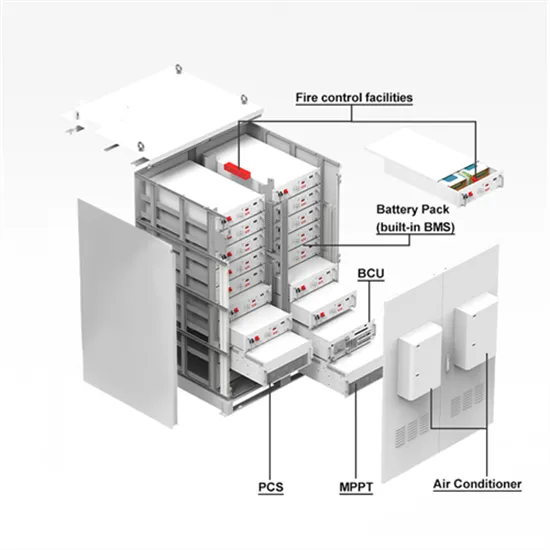

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

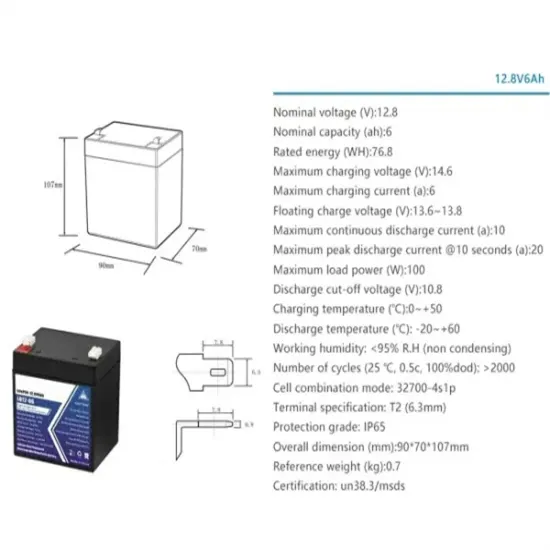

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.